Three-port Counterbalance Cartridge Valve are mainly used to control moving loads to prevent them from running at high speeds, lock the loads in any position, and provide thermal expansion overflow for the oil.

DN10 Counterbalance Cartridge Valve

JBP10-01

Product Introduction:

The Counterbalance Cartridge Valve is a key control element in the hydraulic system. Its core function is to balance the load pressure and prevent the actuator (such as hydraulic cylinder, motor) from moving out of control due to gravity or external force. It dynamically adjusts the flow of oil to ensure that the system remains stable when the load changes suddenly. It is widely used in equipment that requires precise control of lifting, moving or hovering.

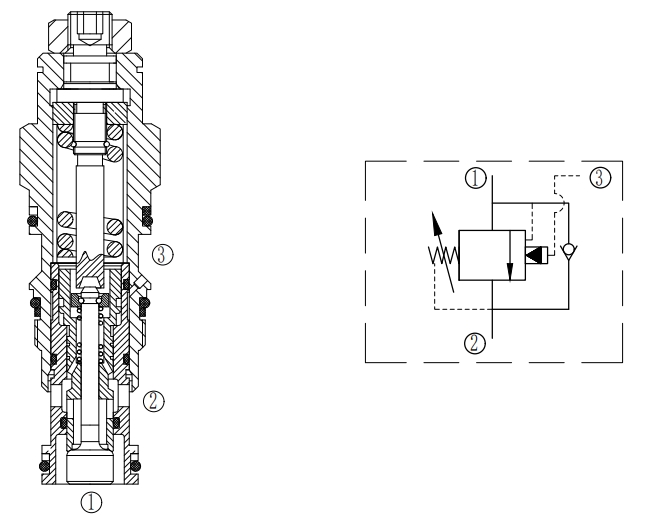

OPERATION:

This valve allows the liquid flow to flow freely from ② to ①, while preventing the reverse flow. If the pressure at the pilot port ③ increases in proportion, the flow from ① to ② will also increase in proportion.

FEATURES:

High-precision pressure regulation, adaptable to various working conditions.

Fast dynamic response, effectively suppressing pressure shock and vibration.

Low internal leakage design: extremely small leakage in the locked state, ensuring long-term stable suspension of the load.

Modular installation: plug-in structure is easy to integrate and reduce pipeline complexity.

Strong pollution resistance: the valve core structure adapts to tiny particles in the hydraulic oil and reduces the failure rate.

SPECIFICATIONS:

Max.Working Pressure:280bar(3118psi)

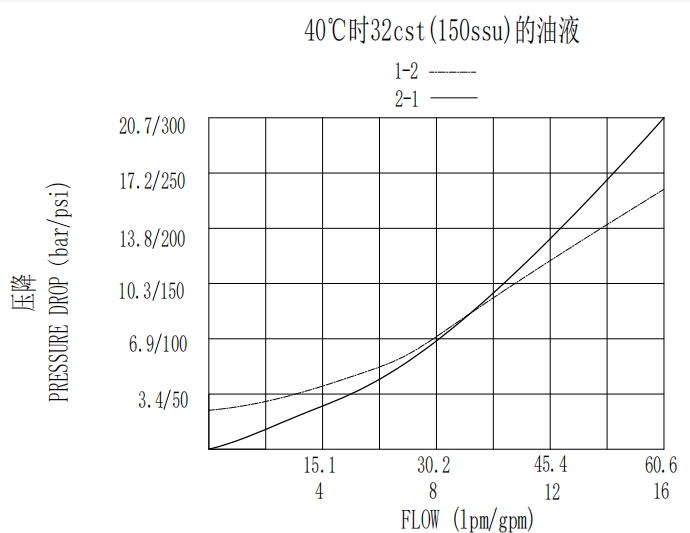

Flow:See performance curve.

Internal leakage:≤0.4mL/min

Pilot Ratio:3:1

Featuresf:The overflow pressure is set to 1.3 times the load value (i.e. the working pressure),② mouth can't bear the total pressure, otherwise it will affect the set pressure.

Filtering Accuracy: 25 μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

Standard Pressure Range: 30~105bar(435~1523psi),75~280bar(1088~4060psi)

CHARACTERISTIC:

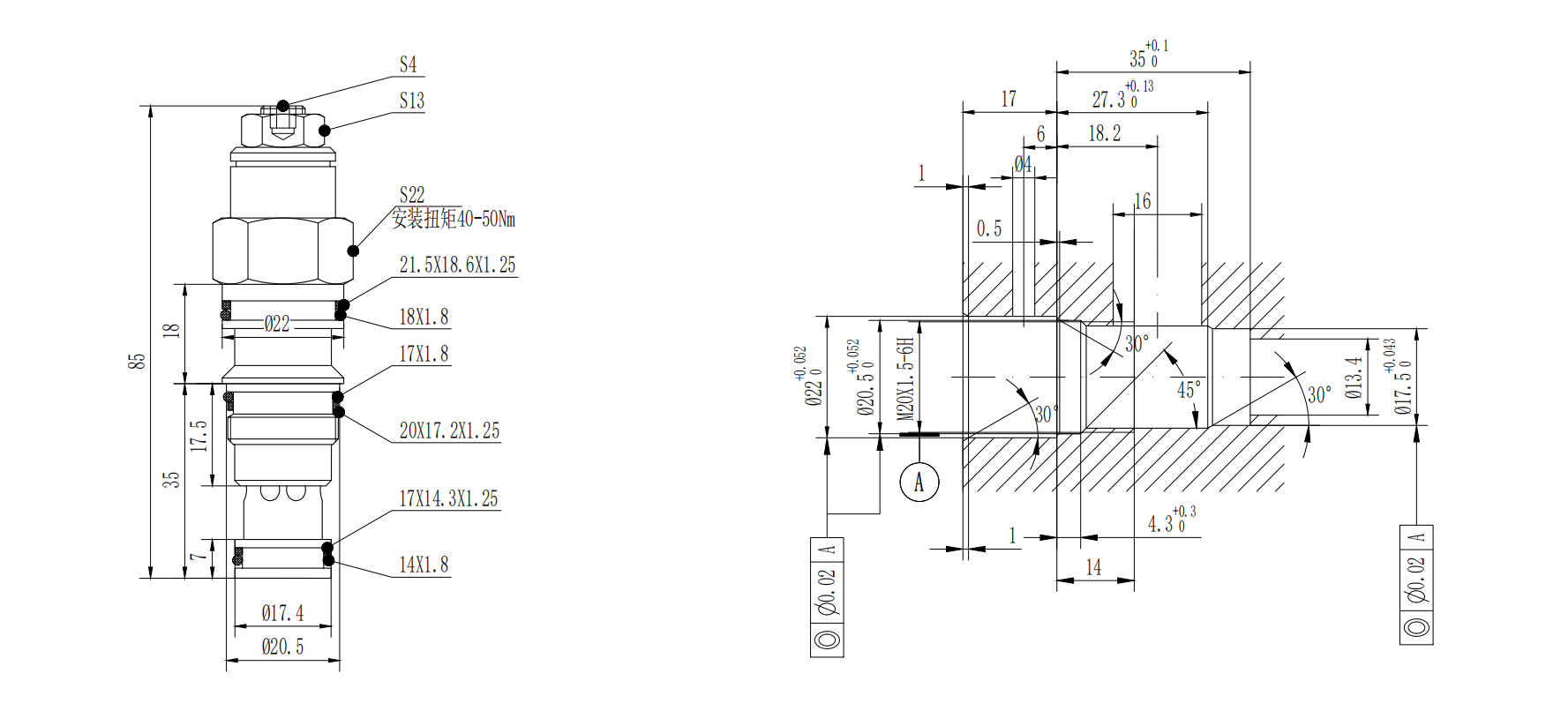

DIMENSIONS:

Application Areas:

Counterbalance Cartridge Valves are widely used in various hydraulic systems, such as construction machinery (such as cranes, excavators, loaders, etc.), mining machinery, metallurgical equipment, marine machinery, and industrial automation production lines. Counterbalance Cartridge Valves are indispensable in any occasion where effective support and precise motion control of the load are required.

FAQ:

What is the function of the Counterbalance Cartridge Valve?

Prevent load from falling: It can prevent load from falling or drifting due to hose or pipe failure, directional control valve core leakage, and provide reliable support for the load when the hydraulic system is abnormal.

Control smooth movement: When the load is in a falling or out-of-control state, and the directional control valve is suddenly closed, smooth and adjustable movement control can be achieved to ensure smooth system operation and reduce shock and vibration.