The CDB-F15 series Manual Sectional Directional Valve and a multi-way reversing valve, so that the vehicle's steering system and the oil cylinder working system share a common oil pump, reducing the complexity of the system structure and facilitating installation and maintenance. The valve is also equipped with a self-locking valve stem to prevent the forklift mast from vibrating due to the negative pressure inside the tilt cylinder, and locks the tilt cylinder when the engine is turned off to prevent the forklift mast from tilting forward and backward due to malfunction, which could cause safety hazards.

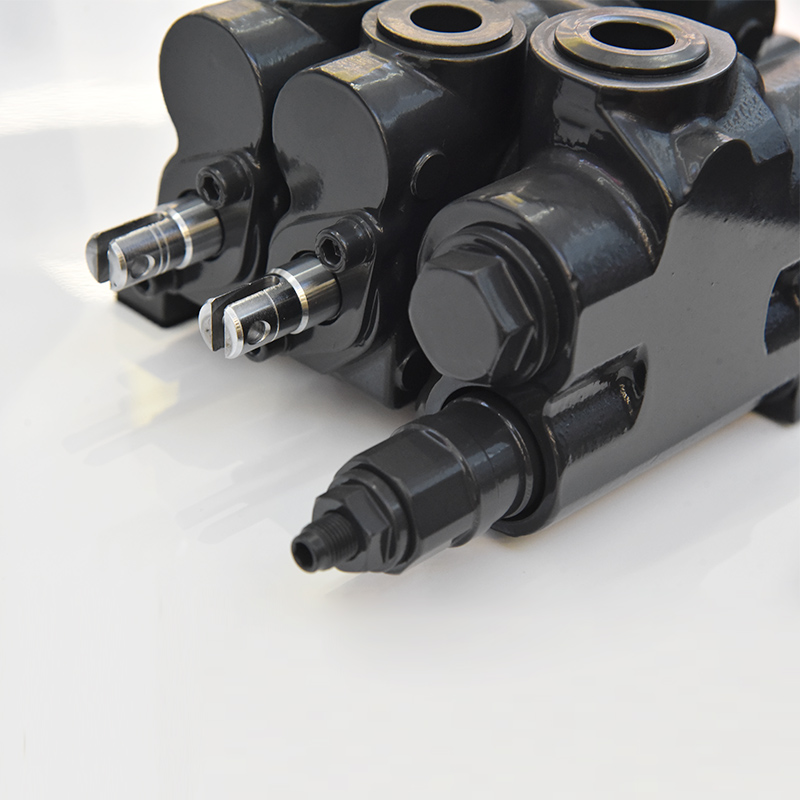

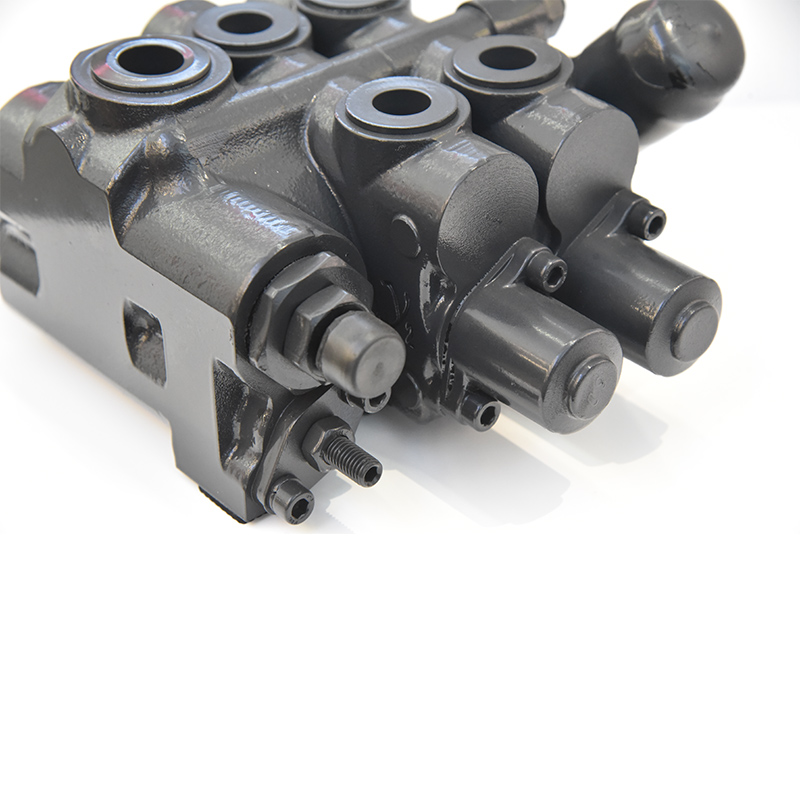

63L/min 2 Bank Manual Sectional Directional Valve

MODEL:CDB-F15 Sectional Directional Valve

Prouduct Features:

CDB2-F15 series multi-way valve is a typical 15-diameter multi-way valve. The oil inlet of the valve stably diverts a part of the flow to supply the steering system; the tilting link has a forward self-locking function. When the forward tilt handle is mistakenly operated after the vehicle is turned off, the mast will not tilt forward, which improves the safety of the operation. This series of multi-way valves has a compact overall structure and is widely used in various engineering vehicles such as 1-3.5T small forklifts and forklifts.

Sectional design: It is composed of multiple independent valve slices. The number of valve slices can be increased or decreased according to demand, and the passages can be flexibly configured.

Parallel and series-parallel systems can be combined in one multi-way valve

The slide valve functions include A, O, O2, Y type, etc. for selection and combination

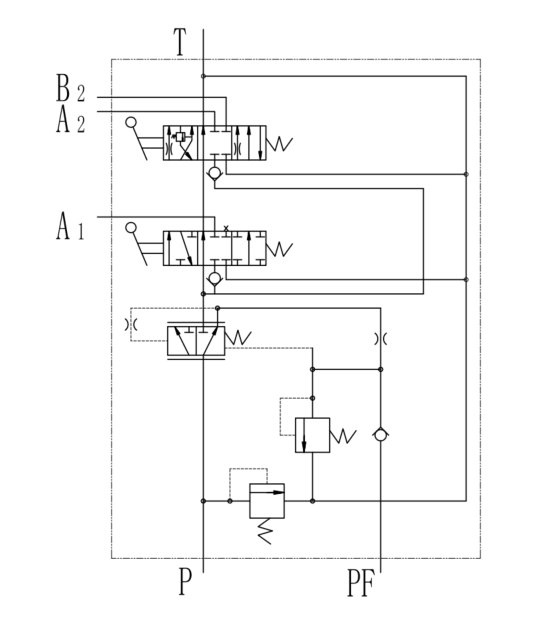

With constant diversion, for steering system selection

The valve core is equipped with a forward brake valve to prevent the danger of cargo tipping caused by misoperation, so as to improve the safety of operation

Since the gap between the valve core and the valve body is extremely small, the internal leakage is very small

The valve core has a variety of positioning and reset mechanisms

Operation mode: mechanical, hydraulic control

Each valve chip is equipped with a one-way valve to prevent oil backflow and overcome the "nodding" phenomenon of the actuator

Built-in plug-in secondary relief valve and oil replenishment valve for users to choose. Regardless of whether the auxiliary valve is installed, the height of the entire valve remains unchanged

The flow and pressure have a wide range of fine control, with excellent fine-tuning characteristics, to achieve smooth and convenient speed control of the actuator

Hydraulic Schematic Diagram:

Specifications:

| Manual Sectional Directional Valve | ||

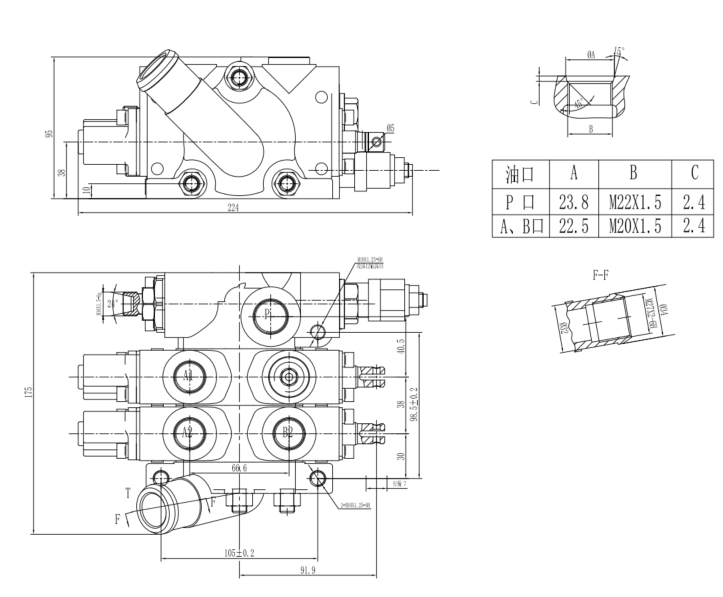

Oil Port Connection Mod | Flanged Connection | |

Control Mod | Pressure Control | |

Installation Mode | See Outline Drawing | |

latus Rectum | mm | 15 |

| Hydraulic Pressure | ||

| Nominal Flow Rate | L/min | 80 |

| Maximum Pressure | bar | 280 |

Maximum Allowable Oil Return Back Pressure | bar | 15 |

| Hydraulic Oil Temperature Range | ℃ | -20~100 |

| Viscosity Range | ㎡/s | 10~460 |

| Permissible Pollution Level of Oil | -/19/16(ISO4406:1999) | |

| Machinery | ||

| Weight | kg | 7.5 |

Maximum Operating Force Allowed By Valve Cor | N | 300 |

(For applications beyond the following parameters, please contact us)

Product Outline Drawing:

Application Areas:

CDB-F15 Manual Sectional Directional Valve is widely used in forklifts, excavators, agricultural machinery, drilling rigs, rotary drilling rigs, logistics handling machinery, mining machinery and other construction machinery.