DCV60 Series Sectional Valves are a high-performance product with a wide range of applications in construction machinery , sanitation machinery and drilling machinery.DCV60 Series Sectional Valves are characterized hy high working pressure , compact structure , good opening and closing characteristics of safety and overload valves , and good versatility.

DCV60 Series Sectional Directional Valve

MODEL:DCV60 Sectional Directional Valve

APPLICATIONS & FEATURES:

DCV60 Series Sectional Valves are simple,compact and heavy duty designed sectional valve from 1 to 12 sections for open and closed center hydralic systems.

Spool function options:O,P,Y,A and etc.

Lever side control options:manual,pneumatic,electric and pneumatic control,hadralic and electric control,hydralic control and remote control.

Compact structure, modular design, easy to integrate.

DCV60 series Sectional Valve are widely used in hydraulic systems of engineering machinery, sanitation machinery, mining machinery and other machinery.

SPECIFICATIONS:

| Nominal Flow | 60 L/min |

| Viscosity Range | 12-75 CST |

| Max.Pressure | 350 bar |

| Internal Leakage | 15cc/min at 160 bar,50℃ |

| Ambient Temp | -40~80℃ |

| Valve structure | Sectional Valve |

| Valve surface | Phosphating treating |

| Valve Sections | 1-12 Sections |

| Rustproof Level | Neutral salt Spray test,48 hours |

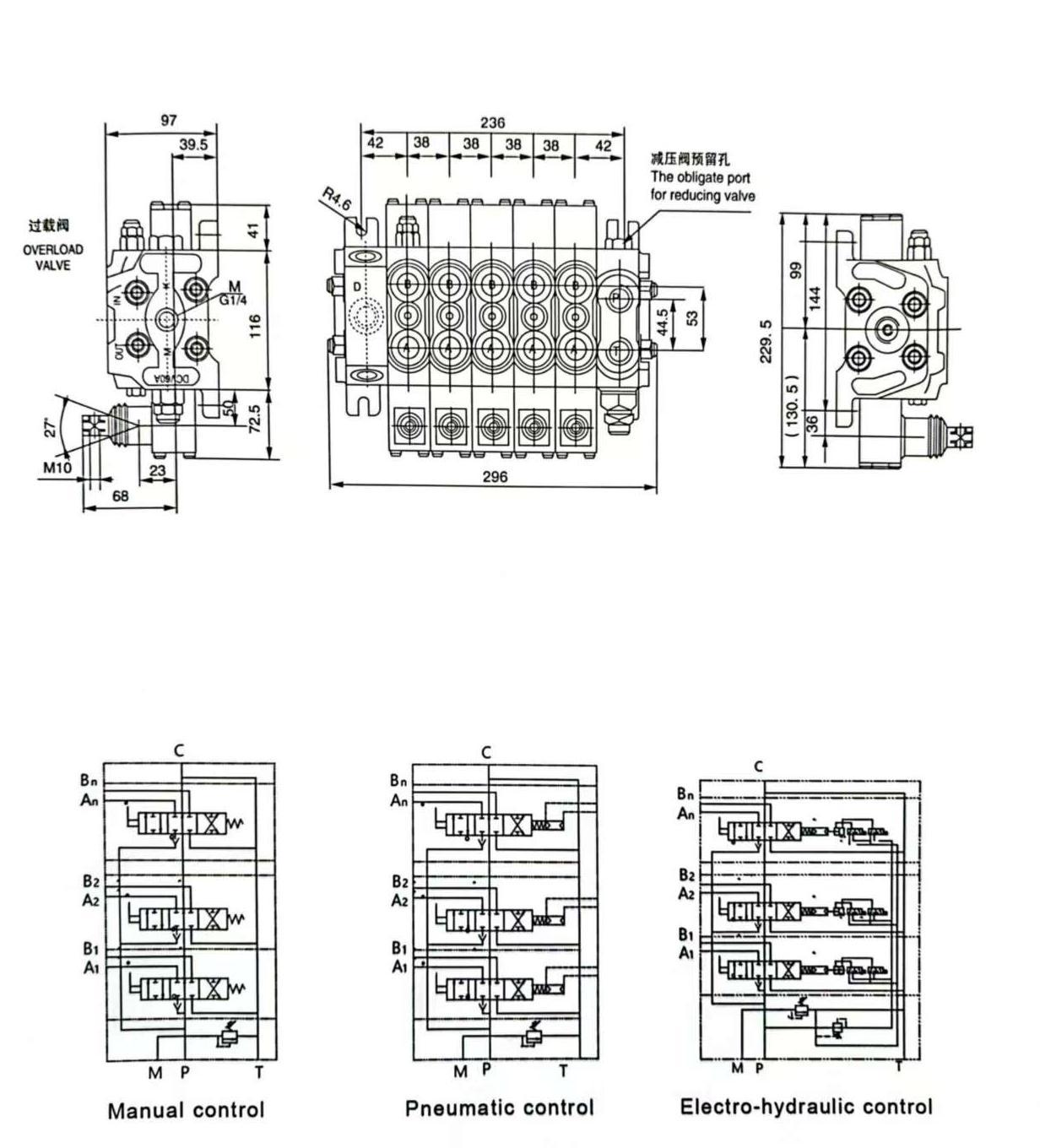

DCV60 SERIES SECTIONAL VALVE DIMENSIONS DATA:

Application Areas:

Engineering machinery: excavators, loaders, cranes, etc., used to control walking, rotation, and cylinder movements.

Special vehicles: sanitation vehicles (garbage trucks, sprinkler trucks), truck cranes, etc., adapted to steering, leveling, and outrigger hydraulic systems.

Mining equipment: drilling rig propulsion systems, breaker hammers, etc., supporting high-pressure and high-flow conditions.

Selection Points:

Flow demand: Select the appropriate DCV60 multi-way valve according to the flow demand of the actuator in the hydraulic system to ensure that its rated flow can meet the working requirements of the system and avoid the situation of slow action or malfunction caused by insufficient flow.

Pressure level: Consider the working pressure of the system and select a DCV60 multi-way valve that can withstand the corresponding pressure to ensure safe and reliable operation under high-pressure environment and prevent problems such as leakage or valve body damage.

Control mode: Select the appropriate control mode according to the actual operation requirements and system control requirements. For example, manual control is suitable for simple operation scenarios, and electro-hydraulic control is suitable for systems that require precise control and high degree of automation.

Valve core function: According to the action requirements of the actuator and the working cycle of the hydraulic system, select a multi-way valve with a suitable valve core function to achieve the required oil circuit switching and action control.

Number of valve plates: According to the number of actuators in the hydraulic system and the complexity of the action, determine the required number of valve plates to ensure that the multi-way valve can meet the control requirements of the system and avoid waste and cost increase caused by too many valve plates.