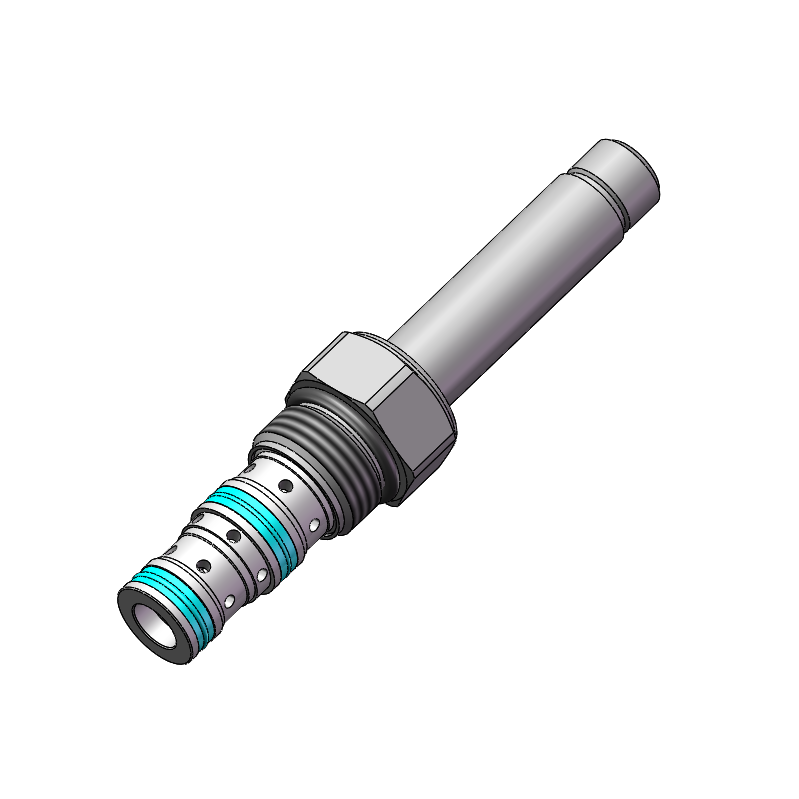

2 Way 2 Position Normally Closed Bi-Directional Cartridge Solenoid Valve designed for load holding applications requiring low leakage.

DN6 2 Way 2 Position Normally Closed Bi-Directional Cartridge Solenoid Valve

JSD06-01

Product Introduction:

A solenoid valve operated, 2-way 2-positions, normally closed, direct acting poppet type, bi-directional blocking, screwin cartridge valve. Special design for low leakage in load holding applications. When the coil is de-energized, the Solenoid Valve blocks flow in both directions. Once the coil is energized, the valve’s poppet opens and allows free flow from 1 to 2 and from 2 to 1. The rigid design using a 1-piece body contributes to minimize the effect of eccentricities in cavity and provides great reliability. Low pressure drop thanks to optimized flow path.

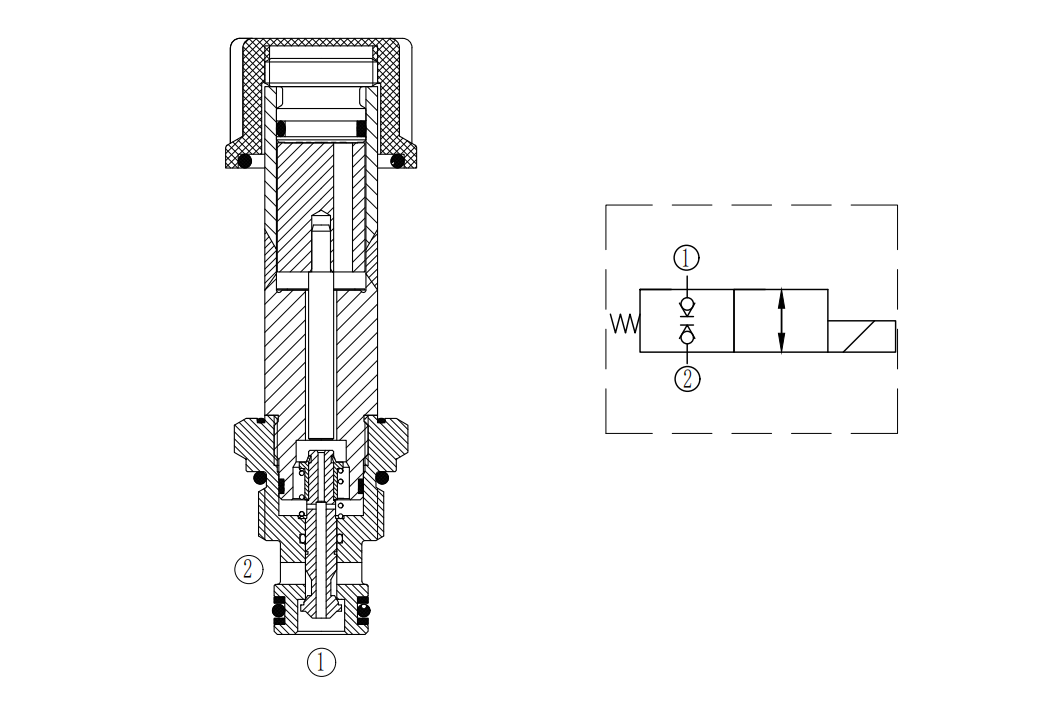

OPERATION:

When the electromagnet is not energized, the bidirectional flow of oil is cut off.

When the electromagnet is energized, the spool opens, allowing oil to flow from 2 to 1 and from 1 to 2.

FEATURES:

Rated electric coils are suitable for continuous operation.

Optional coil voltage and terminal.

All oil ports can be fully pressurized.

Efficient wet armature structure.

Coil integral molded design.

The valve core and valve sleeve are hard to handle and durable.

Industrial universal jack.

Compact structure

SPECIFICATIONS:

Max.Working Pressure:350bar(5075psi)

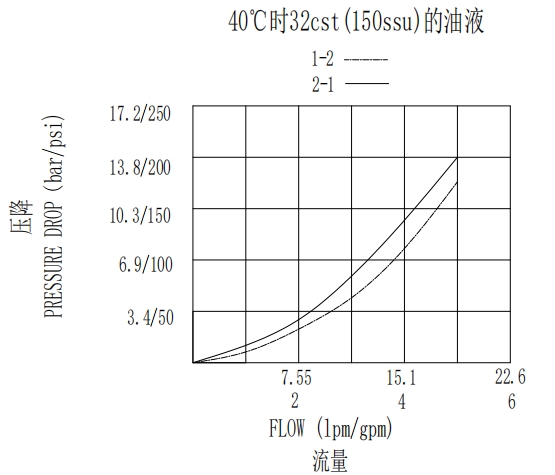

Flow:See performance curve.

Internal leakage:At 350bar, the leakage is ≤1mL/min.

Working Voltage: 12VDC, 24VDC, 110VAC, 220VAC.

Minimum Working Voltage: 85% of normal voltage.

Filtering Accuracy: 20μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

CHARACTERISTIC:

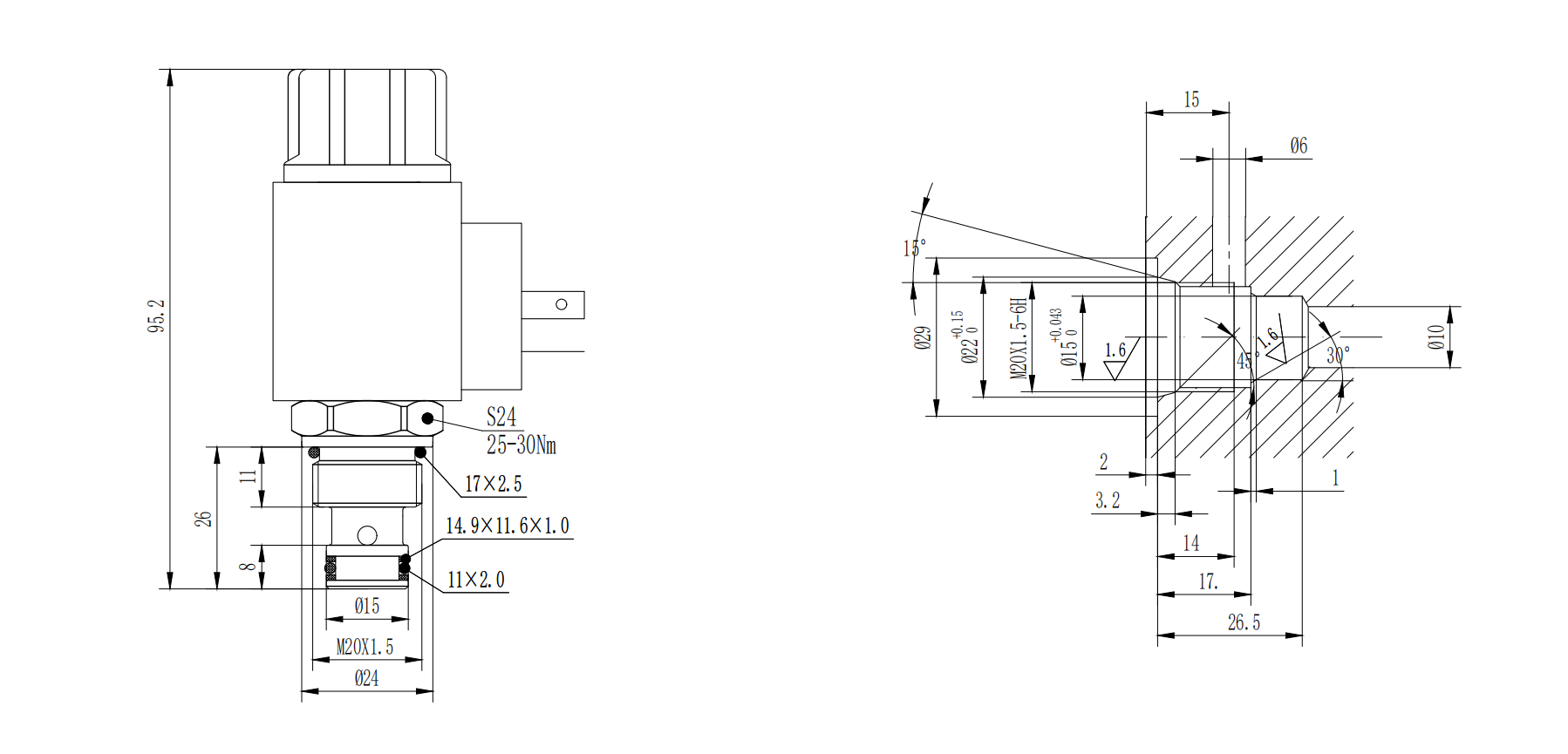

DIMENSIONS:

Application Scenario:

Hydraulic system: In the hydraulic system of engineering machinery, machine tools and other equipment, it is used to control the on and off of hydraulic oil to realize the motion control of actuators (such as hydraulic cylinders and hydraulic motors). For example, in the process of mold closing and mold opening of the injection molding machine, the flow of hydraulic oil is controlled by the solenoid valve to drive the opening and closing of the mold.

Fluid control system: In the fluid transportation and control systems of some chemical, pharmaceutical and other industries, various liquid or gas media are accurately controlled on and off to ensure the stability and safety of the production process. For example, in a chemical reactor, the addition and discharge of reaction raw materials are controlled by the solenoid valve.

FAQ:

What does two-position two-way in a solenoid valve mean?

"Two-position" means that the solenoid valve has two working positions: open and closed. "Two-way" means that the solenoid valve has two channel ports, generally an inlet and an outlet, and the medium is controlled to be on and off between the two channels through the switching action of the solenoid valve.

What is a solenoid cartridge valve?

The solenoid cartridge valve is a hydraulic valve controlled by electromagnetic force. It adopts a cartridge structure (the valve body is embedded in the mounting hole) and consists of a solenoid pilot valve and a main valve.