For Hydraulic Cetop Manifold Block, we have large ultrasonic cleaning machines, high-pressure water cleaning machines, abrasive flow deburring machines, and a complete burr cleaning process for Subplate to ensure the cleanliness of the Subplate. We can design the equipment according to different uses and needs in different situations and according to customer requirements to meet specific performance and functions.

Hydraulic Cetop Manifold Block

Hydraulic Cetop Manifold Block

Core advantages: technology leadership, excellent quality

We have a research and development team composed of senior hydraulic engineers and mechanical design experts. With a deep understanding of fluid mechanics and material science, we continue to break through technical bottlenecks. We use the international cutting-edge CAD/CAM design software, combined with actual working conditions for precise simulation and optimization, to ensure that the internal flow channel design of the Manifold Block and Subplate is scientific and reasonable, the pressure loss is minimized, and the flow control is accurate and correct. In terms of material selection, we strictly select high-strength alloy steel, high-quality cast iron, etc. All raw materials have passed strict quality inspections to ensure product quality from the source.

Product features: customized services to meet diverse needs

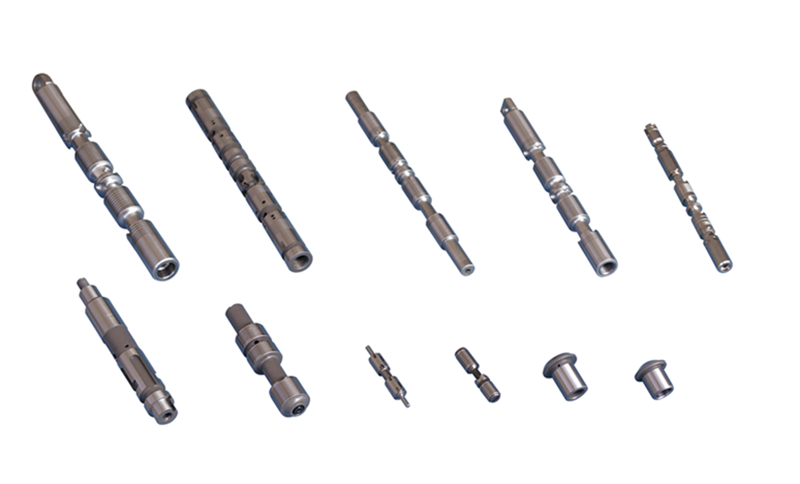

The hydraulic Manifold Blocks and Subplates we produce have excellent versatility and customization capabilities. Whether it is a standard specification product or a non-standard Manifold Block and Subplate designed for special working conditions and complex systems, Manifold Block and Subplate can be perfectly adapted. The surface of the Manifold Block and Subplate has undergone special anti-corrosion treatment, with excellent wear and corrosion resistance, and can operate stably in harsh environments such as high temperature, high pressure, and high humidity. The internal precision-machined valve holes and flow channels, combined with high-precision seals, effectively prevent leakage and ensure efficient operation of the system. At the same time, the Manifold Block and Subplate has a high degree of integration and can integrate multiple functional valves according to customer needs, simplify the system structure, and reduce installation and maintenance costs.

Production process: intelligent manufacturing, excellence

Relying on a modern production base, we have introduced internationally advanced five-axis linkage machining centers, high-precision CNC grinders and other equipment to achieve full process automation from blank processing to finished product assembly. During the production process, we strictly follow the ISO9001 quality management system standards, use online detection, non-destructive testing and other technologies, and monitor each process in real time to ensure that key indicators such as product dimensional accuracy and surface roughness reach the industry-leading level. By continuously optimizing the production process and continuously improving production efficiency, while ensuring Manifold Block and Subplate quality, we can shorten the delivery cycle for customers.

Subplate Subplate Subplate