2 Bank Manual Floating Monoblock Directional Valve,With floating function,This floating principle allows the loader to automatically adjust its height according to the unevenness of the ground during operation, improving work efficiency and safety.

100L/min 2 Bank Manual Floating Monoblock Directional Valve

MODEL:DL20D.2FD Floating Monoblock Directional Valve

Prouduct Features:

This is an Floating Monoblock Directional Valve, designed for small and medium-sized hydraulic systems, suitable for engineering machinery, agricultural equipment or industrial scenarios that need to control multiple actuators (such as hydraulic cylinders, motors). Its core function is to change the direction of the fluid flow through manual operation to achieve reciprocating motion or stop of the actuator, and it has a Float Detent to meet special working conditions.

Two-link design

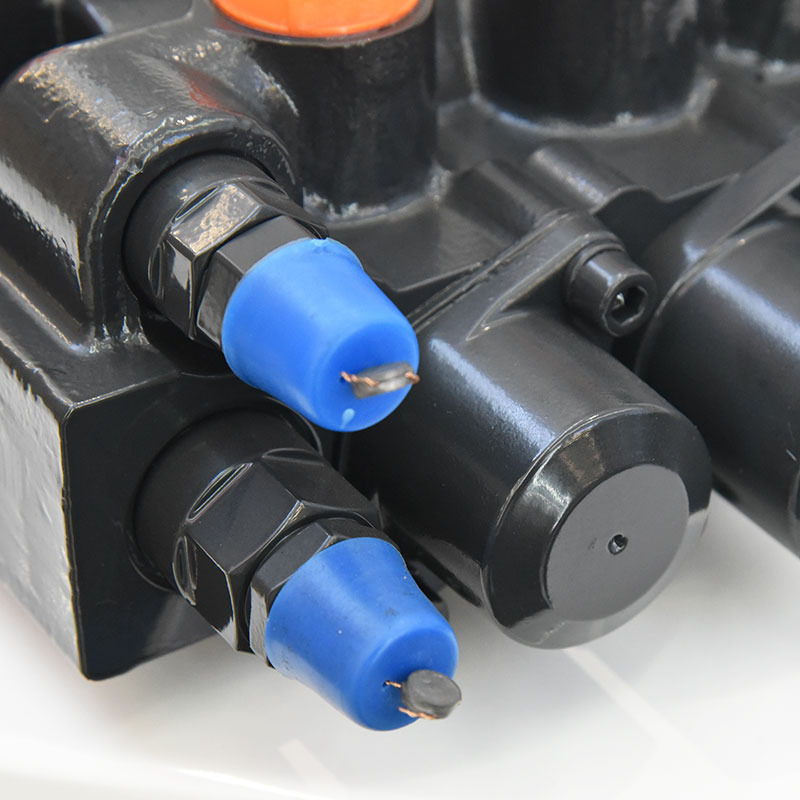

Float Detent: When the valve stem is in the float position, the two chambers of the actuator (such as a hydraulic cylinder) are connected to the tank and the external load can move freely (such as a tractor hanging implements with the terrain).

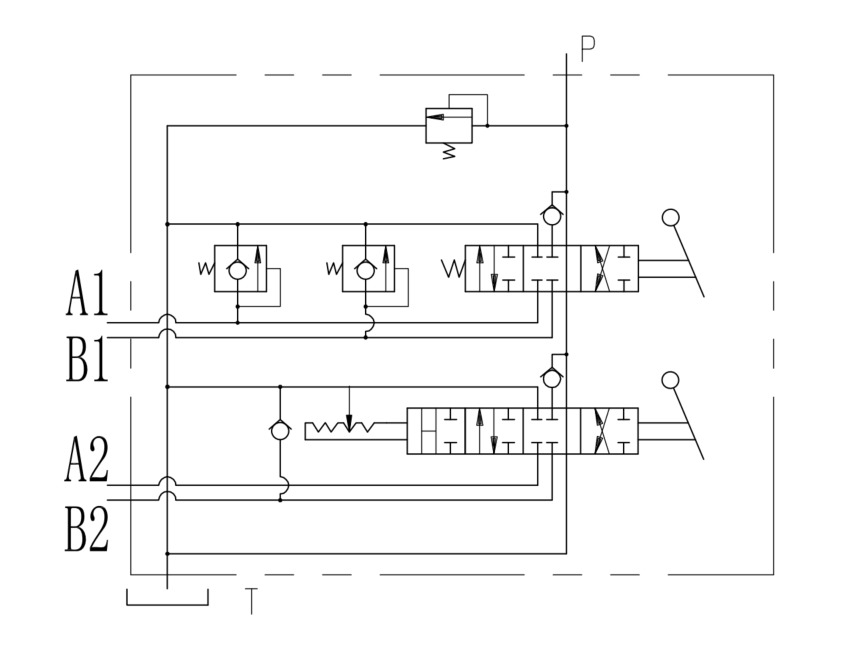

Circuit form: Series and parallel circuits

Manual operation: The valve core position is directly controlled by a mechanical lever or handle, without the need for electrical control or pilot pressure, suitable for power-free environments or simple systems.

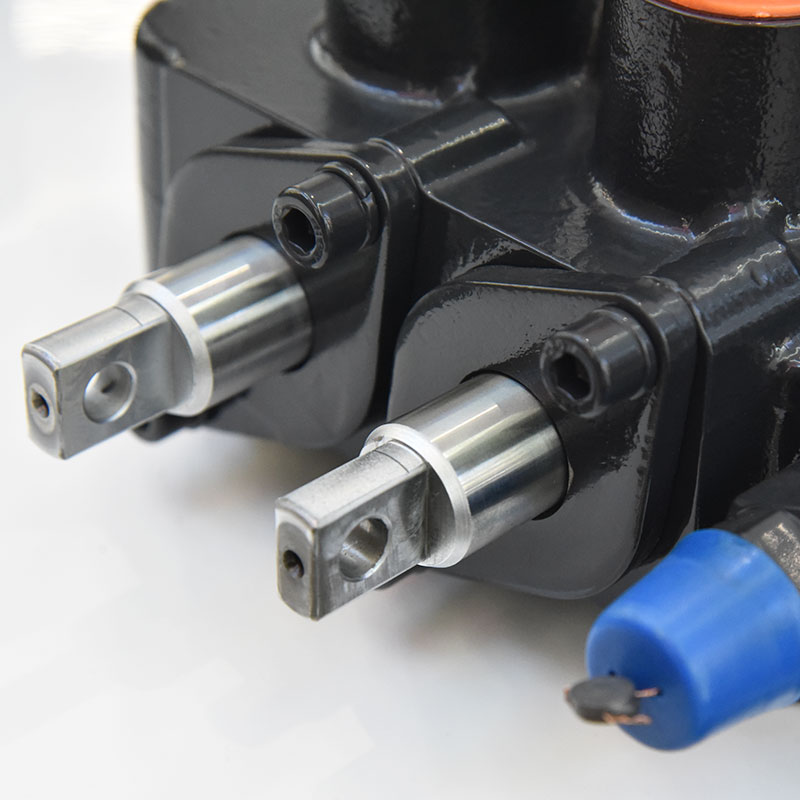

The valve body is a single casting with multiple control modules integrated. It is more compact, has a lower risk of leakage and is easy to install compared to split valves.

Compact structure, space saving, easy installation

Hydraulic Schematic Diagram:

Specifications:

| Floating Monoblock Directional Valve | ||

Oil Port Connection Mod | Threaded Connection | |

Control Mod | Pressure Control | |

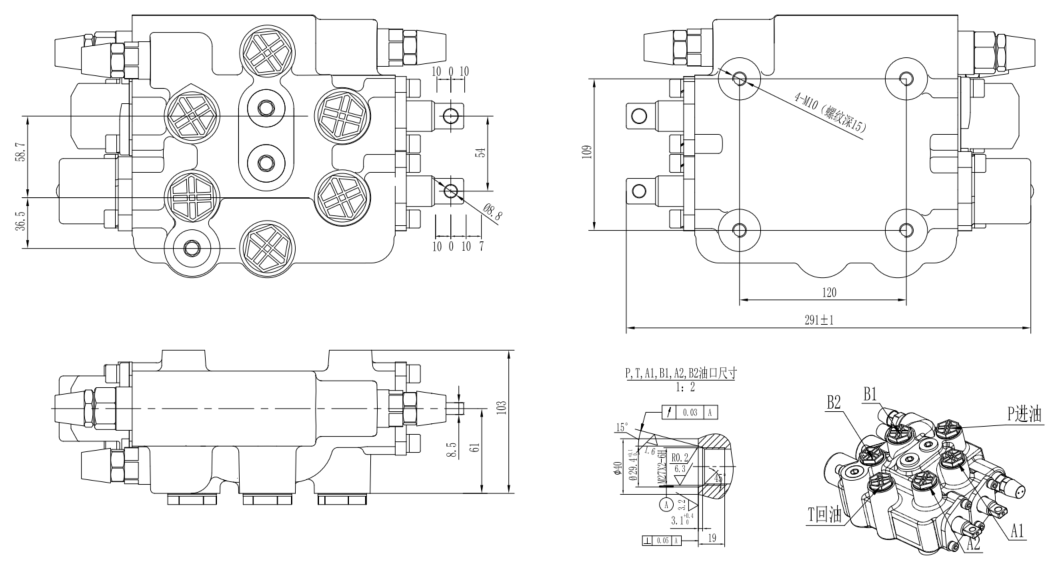

Installation Mode | See Outline Drawing | |

latus Rectum | mm | 20 |

| Hydraulic Pressure | ||

| Nominal Flow Rate | L/min | 100 |

| Maximum Pressure | bar | 280 |

Maximum Allowable Oil Return Back Pressure | bar | 15 |

| Hydraulic Oil Temperature Range | ℃ | -20~100 |

| Viscosity Range | ㎡/s | 10~460 |

| Permissible Pollution Level of Oil | -/19/16(ISO4406:1999) | |

| Machinery | ||

| Weight | kg | 15 |

Maximum Operating Force Allowed By Valve Cor | N | 300 |

Product Outline Drawing:

Application Areas:

Agricultural machinery: tractor suspension system, harvester hydraulic control.

Engineering machinery: small loader bucket lifting, bulldozer blade adjustment.

Industrial equipment: material handling platform, hydraulic clamp control.

Advantages Summary:

Compact structure saves installation space.

Dual module design supports independent control of multiple actuators.

Float Detent enhances equipment adaptability and reduces manual intervention.

Manual operation is reliable and suitable for low-cost systems without electronic control requirements.

FAQ

What is the purpose of the directional valve?

A directional control valve is used in hydraulic systems to precisely control the flow of hydraulic fluid. The valves allow directional control of the fluid by diverting the flow in different directions. Detour from a source to an actuator or from an actuator to the return line are possible.

What is the role of the Float Detent on the loader?

Float Detent Float Detent Float Detent Float Detent