This 3 Spool Monoblock Directional Valve is a high-performance Monoblock Valve independently developed and designed by our company. This 3 Spool Monoblock Directional Valve is specially designed for small and medium-sized loaders. This Monoblock Valve With Floating Function. The boom control joint is equipped with a floating control position.

100L/min 3 Bank Manual Floating Monoblock Directional Valve

MODEL:DL20A.3FD Monoblock Valve With Floating Function

Prouduct Features:

This 3 Spool Monoblock Directional Valve is a high-performance Monoblock Valve independently developed and designed by our company. This 3 Spool Monoblock Directional Valve is specially designed for small and medium-sized loaders. This Monoblock Valve With Floating Function. The boom control joint is equipped with a floating control position.Move the Monoblock Directional Valve stem to the floating joint. At this time, the rodless chamber and the rod chamber of the boom cylinder are connected to the hydraulic oil tank at the same time, and the boom cylinder is in a free floating state with the ground and its own weight, thereby realizing the function of scraping the ground.

Monoblock Valve With Floating Function

Control Mode:Control Manually

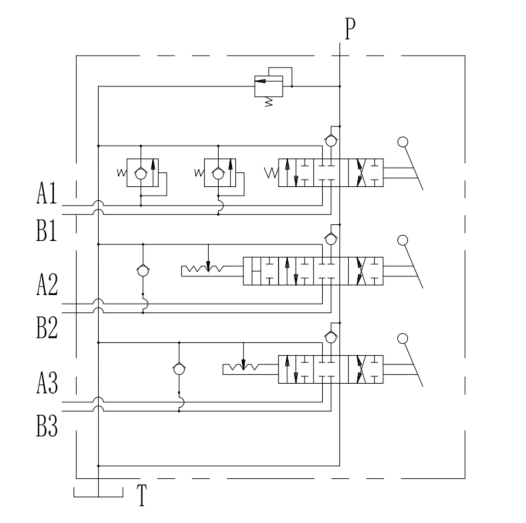

Loop Form:Series and parallel circuits

Float Detent: When the valve stem is in the float position, the two chambers of the actuator (such as a hydraulic cylinder) are connected to the tank and the external load can move freely (such as a tractor hanging implements with the terrain).

The valve body is a single casting with multiple control modules integrated. It is more compact, has a lower risk of leakage and is easy to install compared to split valves.

Hydraulic Schematic Diagram:

Specifications:

| Monoblock Valve With Floating Function | ||

Oil Port Connection Mod | Threaded Connection | |

Control Mod | Pressure Control | |

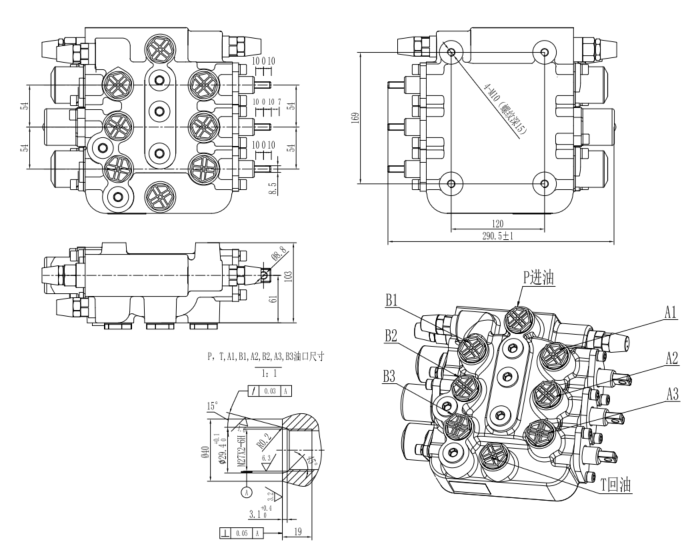

Installation Mode | See Outline Drawing | |

latus Rectum | mm | 20 |

| Hydraulic Pressure | ||

| Nominal Flow Rate | L/min | 100 |

| Maximum Pressure | bar | 280 |

Maximum Allowable Oil Return Back Pressure | bar | 15 |

| Hydraulic Oil Temperature Range | ℃ | -20~100 |

| Viscosity Range | ㎡/s | 10~460 |

| Permissible Pollution Level of Oil | -/19/16(ISO4406:1999) | |

| Machinery | ||

| Weight | kg | 20 |

Maximum Operating Force Allowed By Valve Cor | N | 300 |

Product Outline Drawing:

Typical Application Scenarios:

Agricultural machinery:

When a tractor is hanging agricultural implements (such as plows) on soft ground, the floating function allows the agricultural implements to rise and fall with the terrain to avoid damage caused by hard dragging.

Engineering machinery:

When the bulldozer blade is leveling the ground, the blade can automatically adjust the angle according to the height of the ground to improve the accuracy of the operation.

After the loader bucket is unloaded, the floating position is convenient for quick reset and reduces the number of operating steps.

Industrial equipment:

When people get on and off the hydraulic lifting platform, the floating function eliminates the hydraulic resistance and ensures that the platform is stable and docked.