P40 Series Monoblock Valve with middle-high pressure monoblock directional valve is developed based on Europe technology.

P40 Series Monoblock Directional Valve

MODEL:P40 Monoblock Directional Valve

APPLICATIONS & FEATURES:

P40 Series Monoblock Valve with middle-high pressure monoblock directional valve is developed based on Europe technology.

Inner check valve:The check valve inside the valve body is to insure the hydraulic oil will not be returned.

Inner relief valve: The relief valve inside the valve body is able to adjust the hydraulic system working pressure.

Oil way: Parallel cicuit, power beyond option

Control Way: Manual control, pneumatic control, electric and pneumatic control,hydraulic and electriccontrol and etc.

Valve construction:monoblock construction, 1-7 levers.

Spool Function: A,O,Y.

Option: Hydraulic lock is available to be added A and B port.

P40 Series Monoblock Valve are widely used in the hydraulic systems of forklifts, sanitation vehicles, and small loaders.

One-piece casting valve body with internal integrated oil channel reduces external pipeline connections and reduces leakage risks

Reset mechanism: Spring automatic reset or steel ball positioning to ensure switching stability

SPECIFICATIONS:

Nom.Pressure(MPa) | Max.pressure(MPa) | Nom.Flow rate(L/min) | Max.Flow rate(L/min) | Back pressure(MPa) | Hydraulic oil | ||

Tem.rang (℃) | Visc.rang(mm²/S) | Filtrating accuracy(μm) | |||||

| 20 | 31.5 | 40 | 50 | ≤1 | -20~+80 | 10~400 | ≤10 |

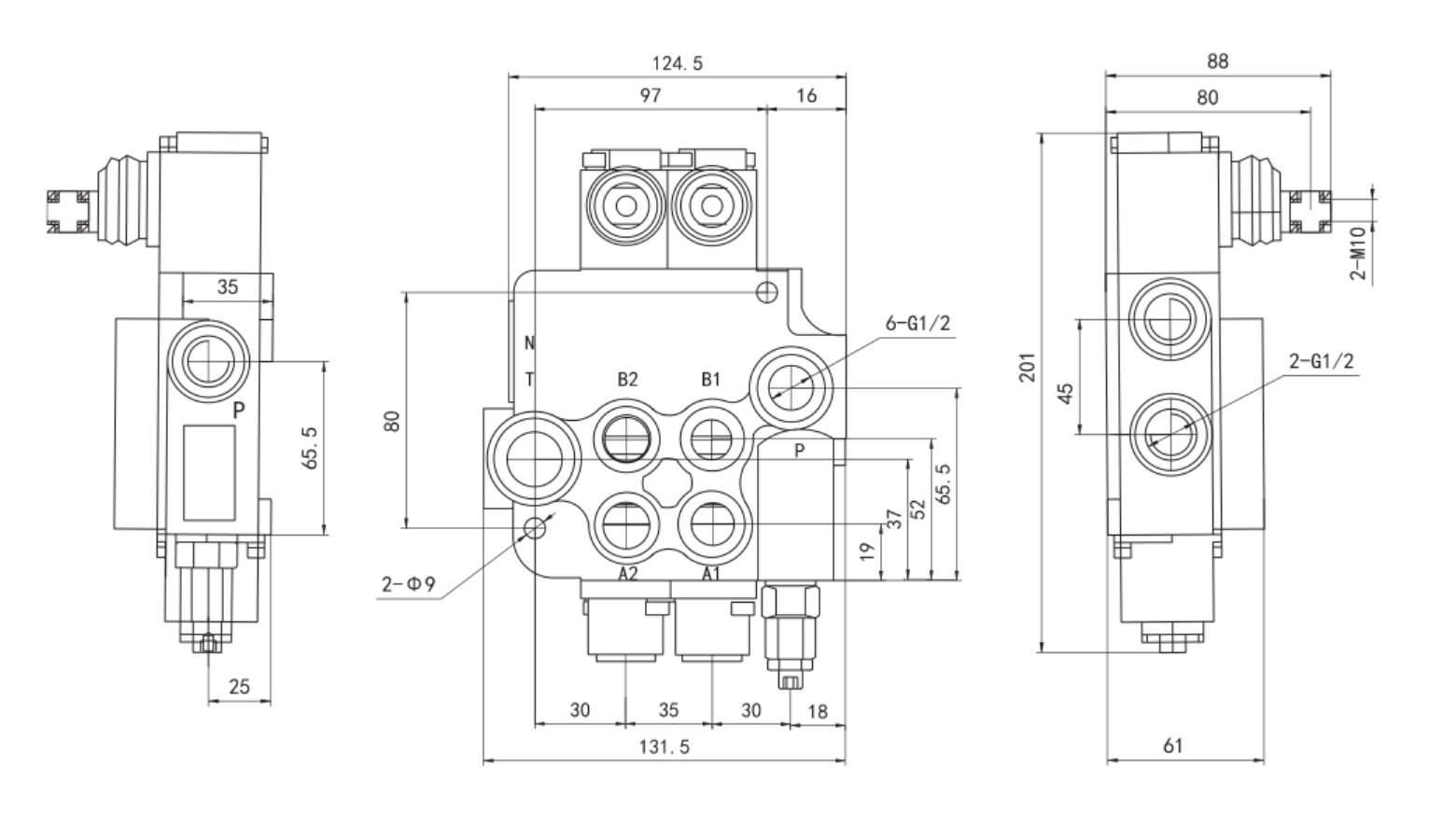

P40 SERIES MONOBLOCK VALVE DIMENSIONS DATA:

Application Areas:

Engineering machinery:

Such as excavators, loaders, bulldozers, forklifts, etc., used to control the actions of various working devices, such as digging, loading, bulldozing, lifting, tilting, etc., to realize various operating functions of engineering machinery.

Sanitation vehicles:

Such as garbage trucks, sprinkler trucks, road sweepers, etc., used to control garbage loading and unloading, opening and closing of sprinkler nozzles, lifting and rotating of road sweepers, etc., to improve the efficiency and quality of sanitation operations.

Drilling machinery:

In drilling equipment, it is used to control the drilling, lifting, rotation and other actions of the drilling rig, as well as the start and stop and flow control of the mud pump to ensure the smooth progress of drilling work.

Selection and maintenance recommendations:

Selection points:

Select the number of links according to the equipment flow requirements, working pressure and number of actuators 3

Installation and Maintenance:

During installation, ensure that the valve body is flat and the bolts are tightened evenly in diagonal order to avoid seal failure. The oil cleanliness is recommended to be below NAS 1638 level 8. Replace the filter element regularly to prevent the valve core from getting stuck