- 锦荣

- 中国

- 30 days

The 2 Bank Manual Reverse Monoblock Valve is modified based on the DL20D.2 multi-way valve to meet special needs. We can customize the design of the integral multi-way valve according to the different needs of customers. Whether it is the number of oil circuits, interface form, or special requirements for flow and pressure control, our professional team can tailor the most suitable product for you to meet your diverse application scenarios.

100L/min 2 Bank Manual Reverse Monoblock Directional Valve

MODEL:DL20B.2 Reverse Monoblock Directional Valve

Prouduct Features:

The 2 Bank Manual Reverse Monoblock Valve is modified based on the DL20D.2 multi-way valve to meet special needs. We can customize the design of the integral multi-way valve according to the different needs of customers. Whether it is the number of oil circuits, interface form, or special requirements for flow and pressure control, our professional team can tailor the most suitable product for you to meet your diverse application scenarios.

Control Mode:Control Manually

Loop Form:Series Circuit

Good Sealing Performance

Overflow Valve And Overload Valve Adopt Plug-in Structure.

Compact Structure And Small Pressure Loss.

Good Universality And Easy Maintenance.

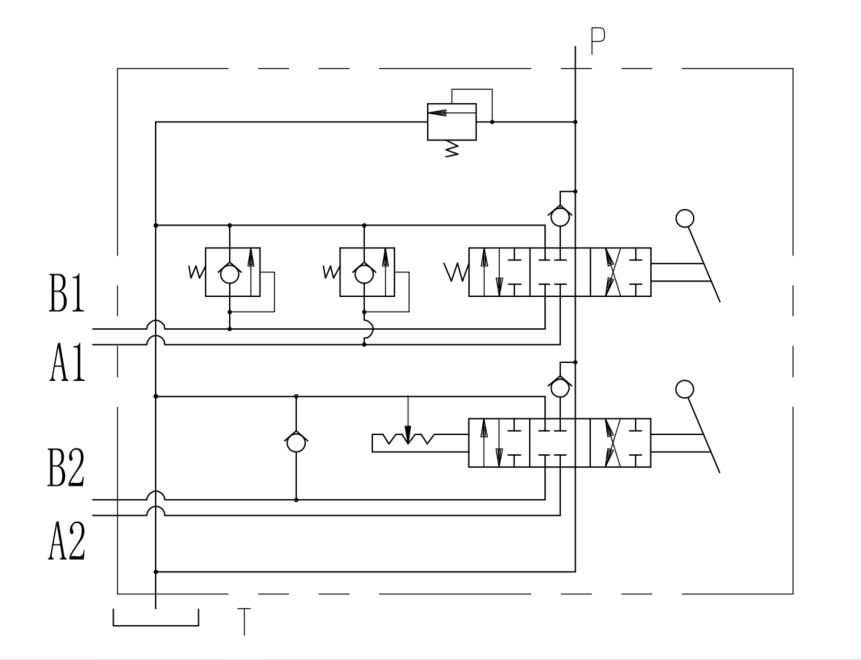

Hydraulic Schematic Diagram:

Specifications:

| Monoblock Directional Control Valve | ||

Oil Port Connection Mod | Threaded Connection | |

Control Mod | Pressure Control | |

Installation Mode | See Outline Drawing | |

latus Rectum | mm | 20 |

| Hydraulic Pressure | ||

| Nominal Flow Rate | L/min | 100 |

| Maximum Pressure | bar | 280 |

Maximum Allowable Oil Return Back Pressure | bar | 15 |

| Hydraulic Oil Temperature Range | ℃ | -20~100 |

| Viscosity Range | ㎡/s | 10~460 |

| Permissible Pollution Level of Oil | -/19/16(ISO4406:1999) | |

| Machinery | ||

| Weight | kg | 15 |

Maximum Operating Force Allowed By Valve Cor | N | 300 |

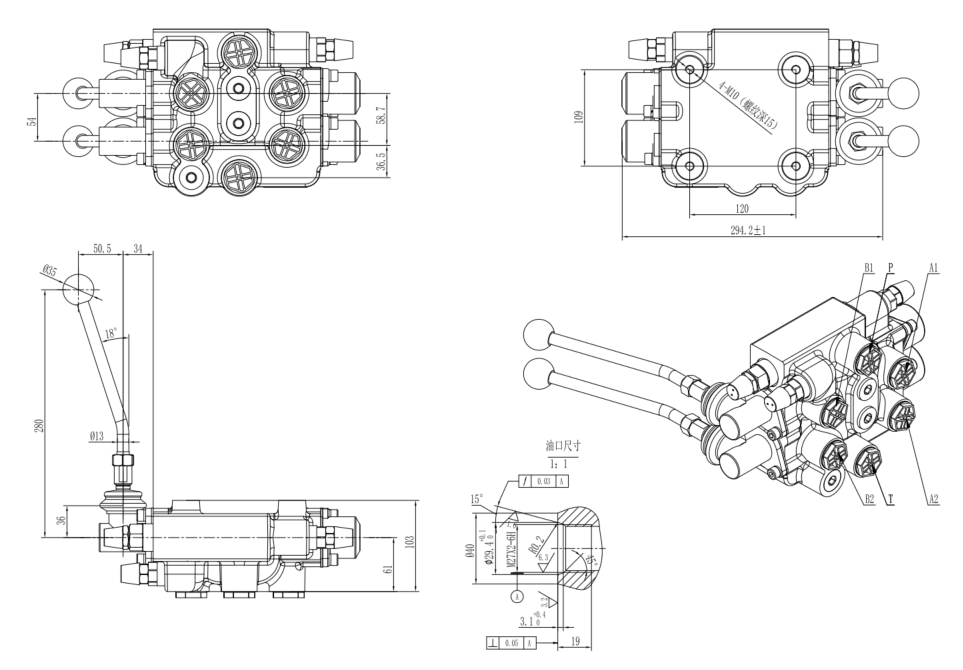

Product Outline Drawing:

Application Scenario:

Engineering machinery field

In engineering machinery such as excavators and loaders, the hydraulic system needs to frequently and accurately control the actions of multiple actuators. This Monoblock Valve can meet the stringent requirements of these equipment for hydraulic control under complex working conditions. For example, when an excavator is digging, it is necessary to accurately control the actions of the boom, dipper, bucket and other components. This Monoblock Valve can achieve fast and stable oil circuit switching to ensure smooth and efficient digging.

Agricultural machinery field

For agricultural machinery such as tractors and combine harvesters, their hydraulic systems not only need to control the lifting and flipping of agricultural implements, but also need to cope with the complex and changing working environment in the field. The compact structure and reliable performance of this Monoblock Valve enable it to adapt to the working characteristics of agricultural machinery. For example, when a tractor pulls agricultural implements for ploughing, the Monoblock Valve can accurately control the depth of the agricultural implements and the lifting height according to different soil conditions, thereby improving the quality and efficiency of the operation.

Industrial automation equipment field

On industrial automation production lines, various hydraulically driven actuators require high-precision and high-response speed control. This Monoblock Valve valve can quickly and accurately realize oil circuit reversal and flow regulation, meeting the needs of automated equipment for efficient and stable operation. For example, in automated assembly equipment, the Monoblock Valve can control the hydraulic manipulator to accurately grasp and transport parts, ensuring efficient and accurate production processes.