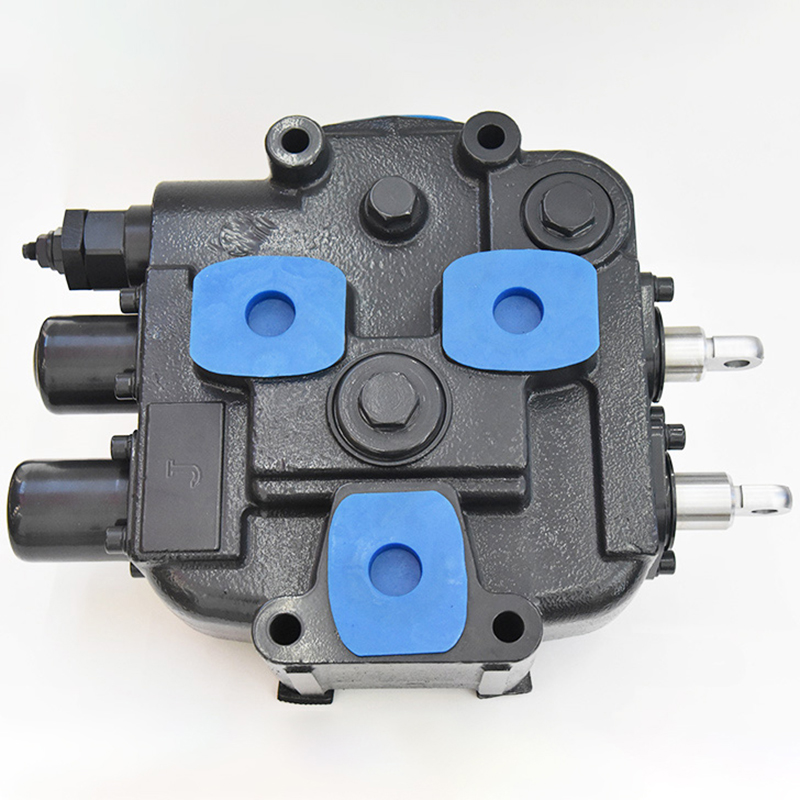

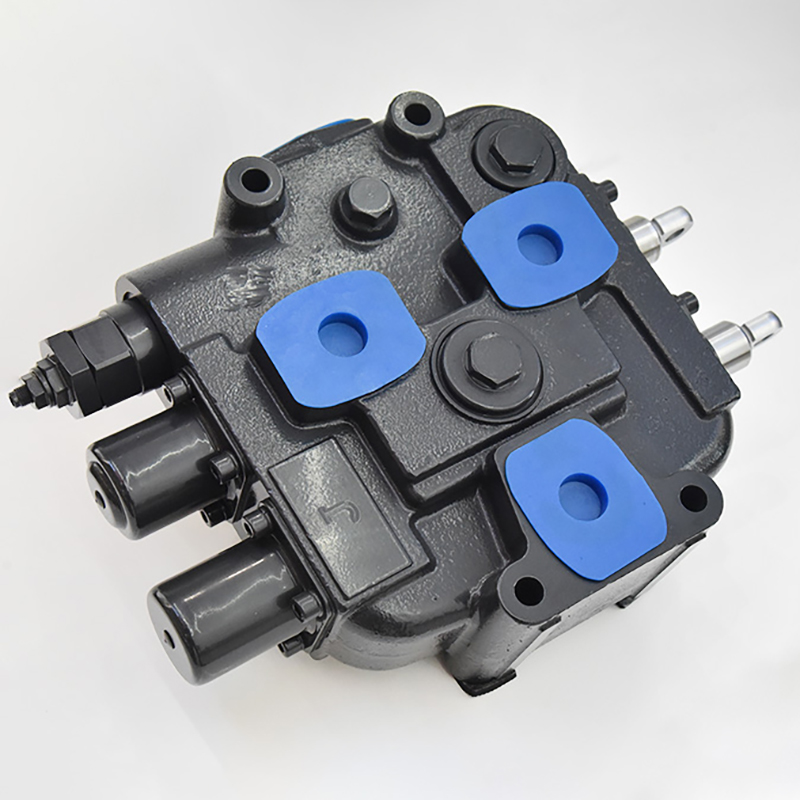

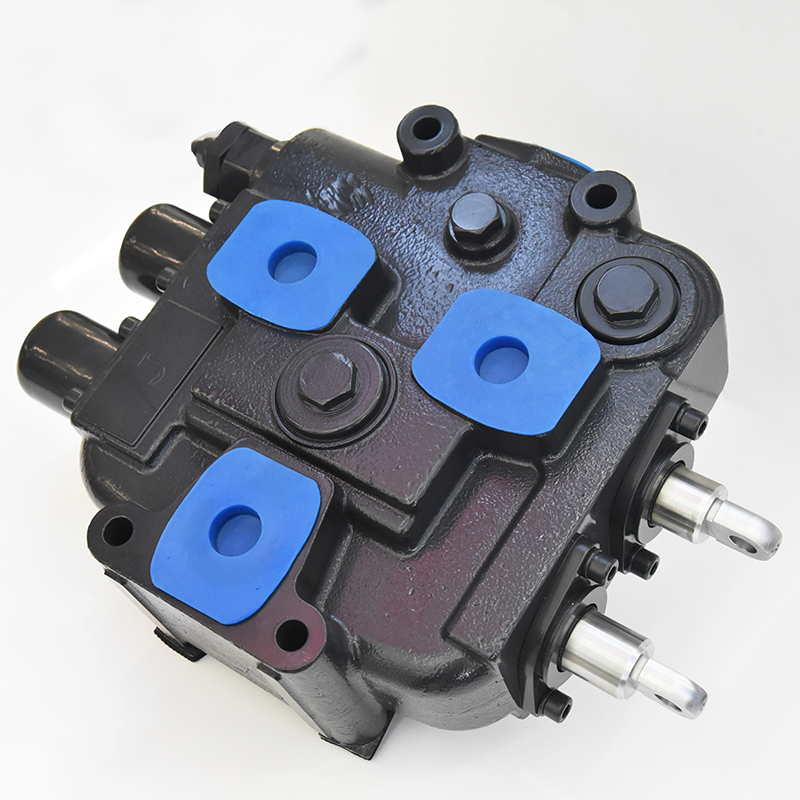

DF25 series 2 Bank Monoblock Directional Valve is an integral structure, the oil circuit is in series, the operation mode is a manual slide valve 2 Bank Monoblock Directional Valve, each working oil port can be equipped with a superimposed structure of the overload valve and the oil replenishment valve, the position of which can be flexibly combined according to user requirements.

160L/min 2 Bank Manual Monoblock Directional Valve

MODEL:DF25L.2 Monoblock Directional Valve

Prouduct Features:

DF25 series 2 Bank Monoblock Directional Valve is an integral structure, the oil circuit is in series, the operation mode is a manual slide valve 2 Bank Monoblock Directional Valve, each working oil port can be equipped with a superimposed structure of the overload valve and the oil replenishment valve, the position of which can be flexibly combined according to user requirements. The 2 Bank Monoblock Directional Valve has the characteristics of high pressure, large flow, small pressure loss, good micro-motion, complete additional valves, small operating force, compact structure, reliable operation, easy maintenance, etc. It is suitable for the hydraulic system of large and medium-sized engineering machinery such as loaders and bulldozers to realize the centralized work of multiple working mechanisms.

Operation:

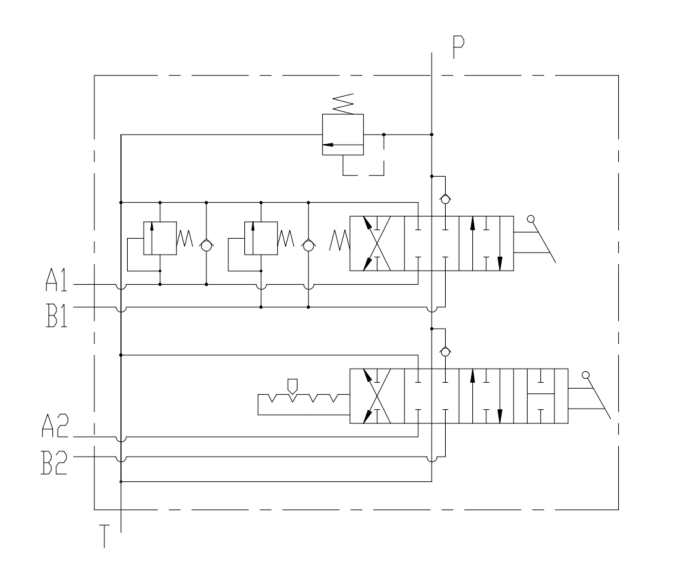

DF25 series Monoblock Directional Valve mainly changes the flow direction and on-off of hydraulic oil by moving the valve core in the valve body, thereby realizing the control of multiple actuators. When the control handle or hydraulic control signal acts on the multi-way valve, the valve core will produce corresponding displacement, so that the oil inlet is connected or disconnected with different working oil ports, thereby controlling the extension and retraction of the hydraulic cylinder, the rotation of the hydraulic motor and other actions to meet the action requirements of different working parts of equipment such as construction machinery.

Hydraulic Schematic Diagram:

Specifications:

| 2 Bank Monoblock Directional Valve | ||

Oil Port Connection Mod | Flanged Connection | |

Control Mod | Pressure Control | |

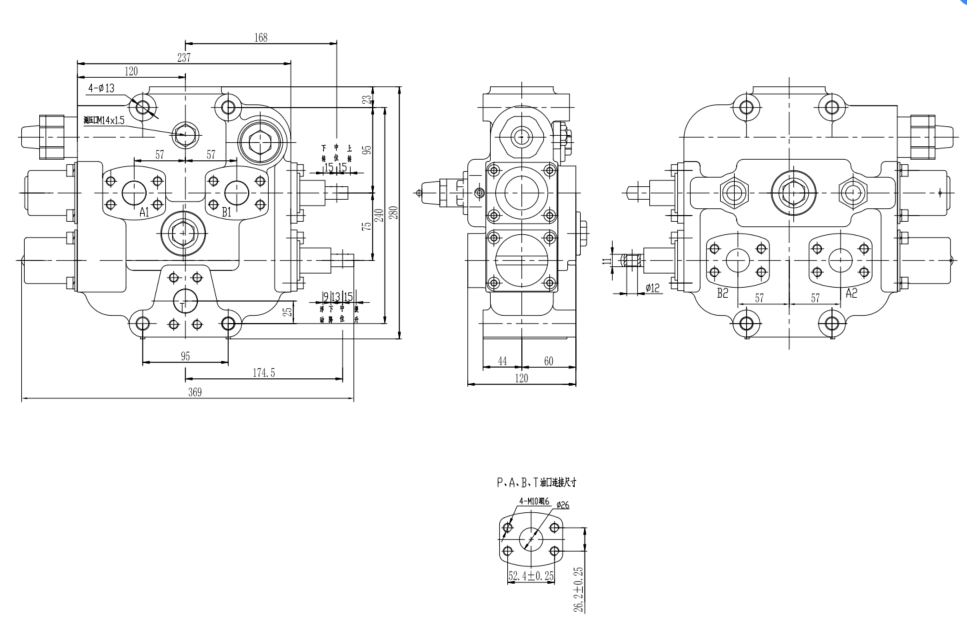

Installation Mode | See Outline Drawing | |

latus Rectum | mm | 25 |

| Hydraulic Pressure | ||

| Nominal Flow Rate | L/min | 160 |

| Maximum Pressure | bar | 280 |

Maximum Allowable Oil Return Back Pressure | bar | 15 |

| Hydraulic Oil Temperature Range | ℃ | -20~100 |

| Viscosity Range | ㎡/s | 10~460 |

| Permissible Pollution Level of Oil | -/19/16(ISO4406:1999) | |

| Machinery | ||

| Weight | kg | 32 |

Maximum Operating Force Allowed By Valve Cor | N | 300 |

Product Outline Drawing:

Application Areas:

Engineering machinery: excavators, loaders, bulldozers, rollers, etc.

Agricultural machinery: tractors, combine harvesters, seed drills, etc.

Construction and municipal equipment: concrete pump trucks, aerial work platforms, garbage compactors

Mining and heavy-duty equipment: mining trucks, rock drills, underground mining equipment

Material handling equipment: forklifts, cranes, automated warehousing systems

Special vehicles and emergency equipment: fire trucks, tow trucks, emergency rescue vehicles