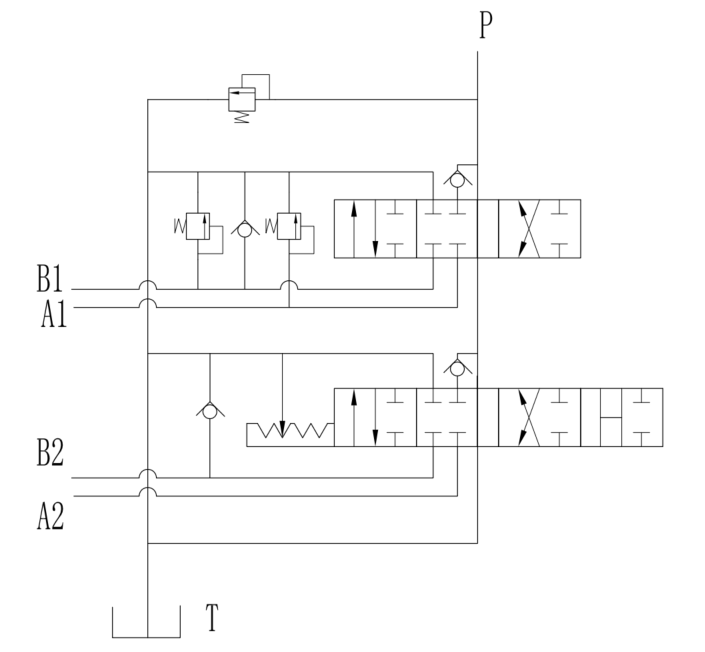

Compared with the traditional DF32 Monoblock Directional Valve, the DF32H.2 oil filling Monoblock Directional Valve adds two separate one-way oil supply valves on the valve body, which simplifies the structure of the original overload valve and improves its reliability.

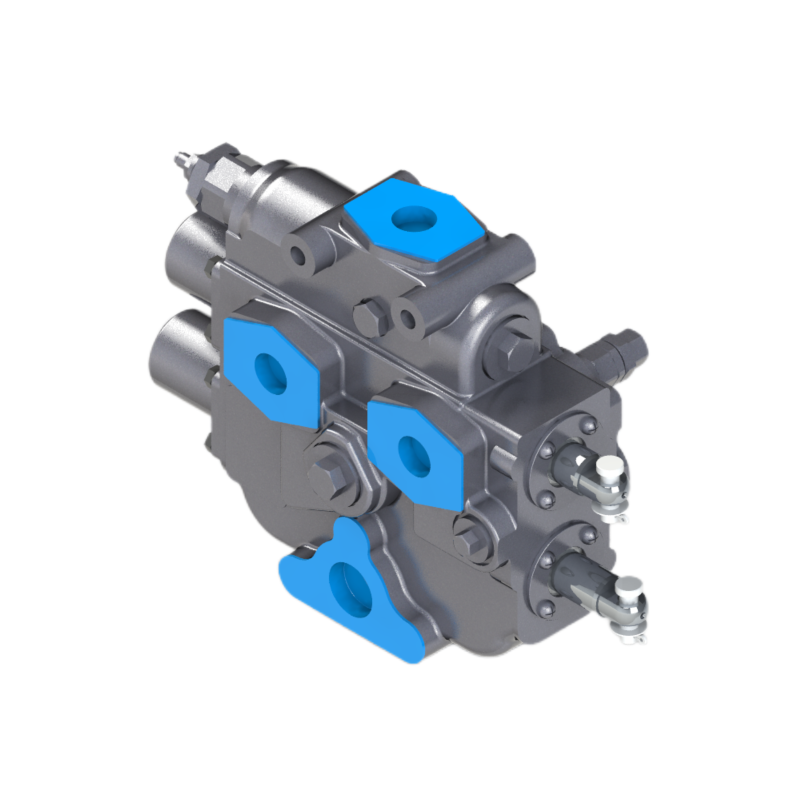

250L/min 2 Bank Manual Oil Filling Monoblock Directional Valve

MODEL:DF32H.2 Monoblock Directional Valve

Prouduct Features:

Compared with the traditional DF32 Monoblock Directional Valve, the DF32H.2 oil filling Monoblock Directional Valve adds two separate one-way oil replenishment valves on the valve body, which simplifies the structure of the original overload valve and improves its reliability. The added bucket oil replenishment valve increases the diameter, making its oil replenishment capacity sufficient and reliable, better protecting the bucket oil cylinder, and making up for the problems of the original overload oil replenishment valve used in the DF32 Monoblock Directional Valve bucket small cavity, such as complex structure, high oil replenishment opening pressure, small diameter and weak oil replenishment capacity. The main function of the added boom oil replenishment valve is to ensure that the hydraulic system can provide sufficient oil replenishment flow during the boom descent process, thereby preventing the boom from dropping too fast due to its own weight. The pressure fluctuation and impact of the system.

Hydraulic Schematic Diagram:

Specifications:

| oil filling Monoblock Directional Valve | ||

Oil Port Connection Mod | Flanged Connection | |

Control Mod | Pressure Control | |

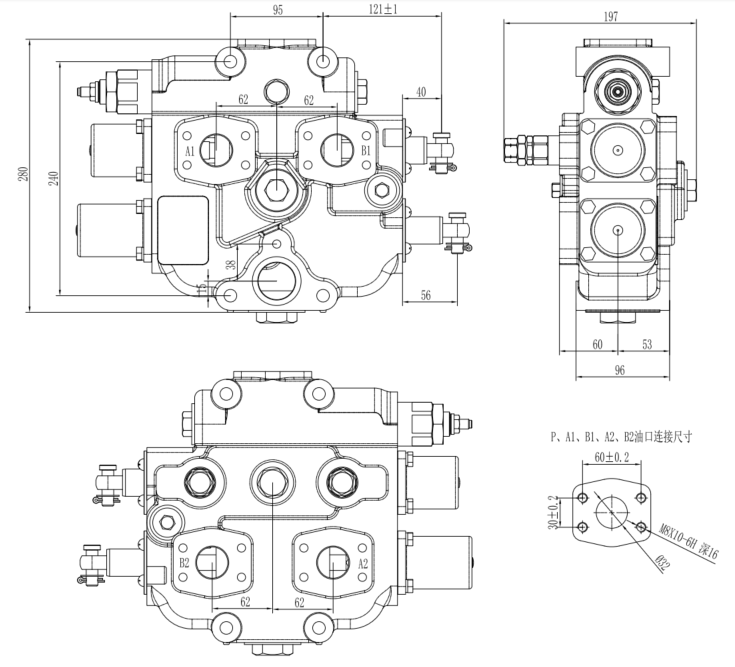

Installation Mode | See Outline Drawing | |

latus Rectum | mm | 32 |

| Hydraulic Pressure | ||

| Nominal Flow Rate | L/min | 250 |

| Maximum Pressure | bar | 280 |

Maximum Allowable Oil Return Back Pressure | bar | 15 |

| Hydraulic Oil Temperature Range | ℃ | -20~100 |

| Viscosity Range | ㎡/s | 10~460 |

| Permissible Pollution Level of Oil | -/19/16(ISO4406:1999) | |

| Machinery | ||

| Weight | kg | 36 |

Maximum Operating Force Allowed By Valve Cor | N | 300 |

Product Outline Drawing:

Typical Application Scenarios:

Engineering machinery: boom/bucket control of excavators and loaders.

Agricultural equipment: hydraulic lifting system of tractors, steering mechanism of harvesters.

Industrial equipment: direction and pressure control of injection molding machines and hydraulic presses.

Shipbuilding and heavy industry: multi-actuator collaborative operation of deck machinery and cranes.

FAQ:

What is the working principle of the oil replenishment check valve?

Structural features:

It is usually a spring-loaded one-way valve, installed on the low-pressure side or return oil circuit of the multi-way valve, and connected to the oil tank or the oil replenishment pipeline.

Working logic:

1.When the pressure on the low-pressure side of the system is lower than the opening pressure of the replenishment valve (such as 0.3~0.5MPa), the valve core is pushed open by the spring, and the oil flows into the system from the replenishment pipeline.

2.When the system pressure returns to the normal range, the replenishment valve automatically closes to prevent oil backflow.