DCV140 Series Sectional Valve are a high-performance product with a wide range of applications in construction machinery , sanitation machinery and drilling machinery.DCV140 Series Sectional Valves are characterized hy high working pressure , compact structure , good opening and closing characteristics of safety and overload valves , and good versatility.

DCV140 Series Sectional Directional Valve

MODEL:DCV140 Sectional Directional Valve

APPLICATIONS & FEATURES:

The DCV60 multi-way directional valve is a medium- and high-pressure Sectional Directional Valve.

The valve can be equipped with overflow valves, overload valves, check valves, oil replenishment valves, etc. according to customer requirements. The overflow valve can adjust the system pressure, the overload valve controls the working pressure of a single oil chamber, and the check valve prevents oil backflow.

The valve adopts parallel oil circuits.

The directional valve slide valve functions include A, o, Y, P, etc., which can be combined arbitrarily

The pressure output port is designed to connect with other hydraulic components to provide power source.

The specially designed sealing method makes the valve have excellent sealing performance.

The reversing handle has two installation forms to facilitate operation in different directions

The valve is widely used in the hydraulic systems of engineering machinery such as forklifts, sanitation vehicles, and small loaders.

SPECIFICATIONS:

| Nominal Flow | 140 L/min |

| Viscosity Range | 12-75 CST |

| Max.Pressure | 350 bar |

| Internal Leakage | 15cc/min at 160 bar,50℃ |

| Ambient Temp | -40~80℃ |

| Valve structure | Sectional Valve |

| Valve surface | Phosphating treating |

| Valve Sections | 1-12 Sections |

| Rustproof Level | Neutral salt Spray test,48 hours |

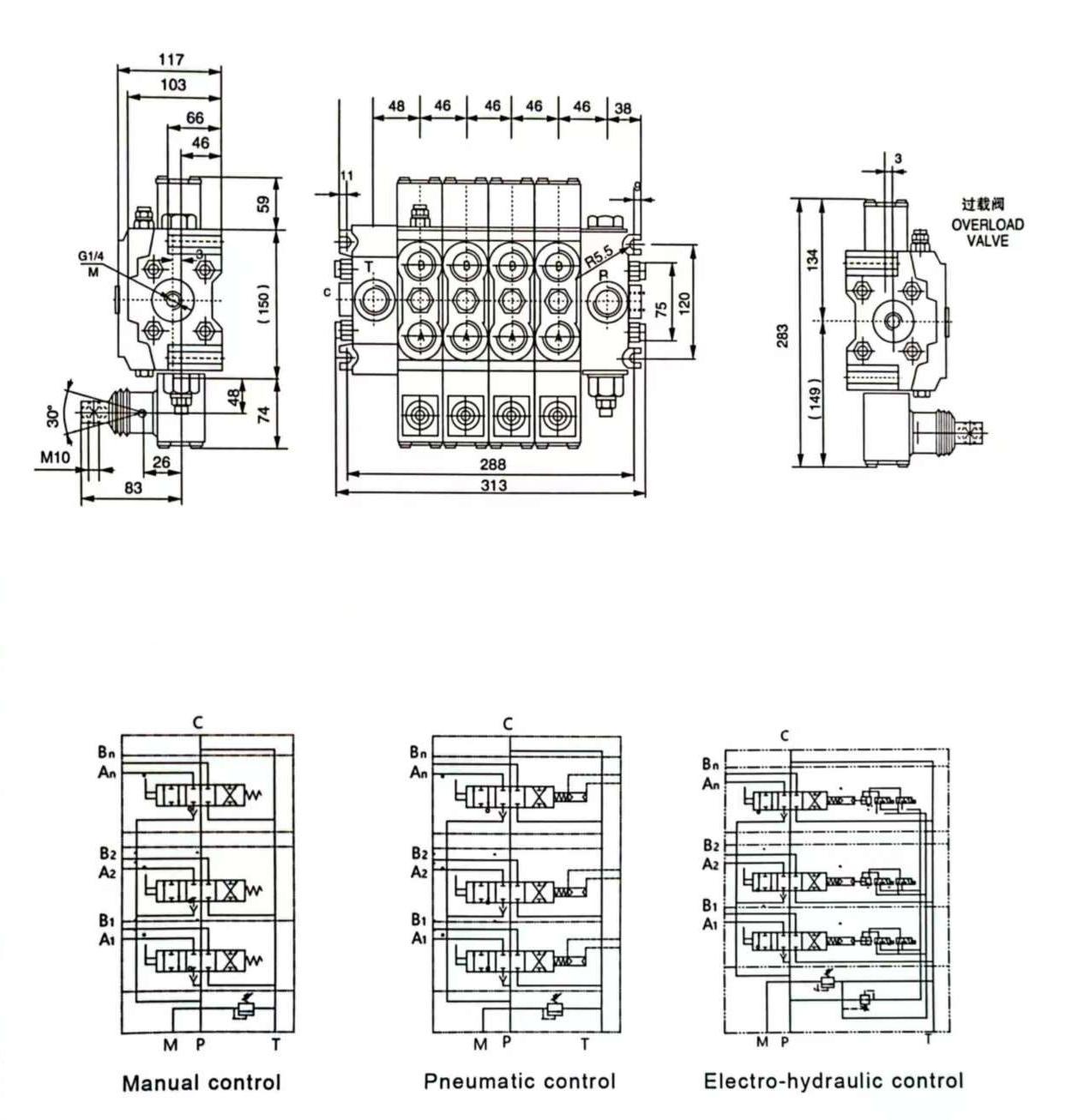

DCV140 SERIES SECTIONAL VALVE DIMENSIONS DATA:

Precautions For Use:

Prevent pollution: The cleanliness of hydraulic oil is crucial to the normal operation of the DCV140 Series Sectional Valve. The hydraulic oil and filter should be replaced regularly to prevent impurities and particles in the oil from entering the valve, causing valve core jamming, wear and other faults.

Correct installation: When installing the DCV140 Series Sectional Valve, it should be installed correctly according to the requirements of the instructions to ensure that the installation is firm and the connecting pipeline is leak-free to avoid system failures caused by improper installation.

Reasonable use: The operator should be familiar with the operation method and control function of the DCV140 Series Sectional Valve, operate it according to the operating procedures, and avoid equipment damage or safety accidents caused by misoperation.

Regular maintenance: Regularly inspect and maintain the DCV140 Series Sectional Valve, check the wear of the valve core, valve seat, spring and other components, and replace damaged components in time to ensure the performance and reliability of the Sectional Directional Valve.