DCV20 Series Monoblock Valve are a high-performance product with a wide range of applications in construction machinery , sanitation machinery and drilling machinery.DCV20 Series Monoblock Valves are characterized hy high working pressure , compact structure , good opening and closing characteristics of safety and overload valves , and good versatility.

DCV20 Series Monoblock Directional Valve

MODEL:DCV20 Monoblock Directional Valve

APPLICATIONS & FEATURES:

DCV20 Series Monoblock Valves are simple,compact and heavy duty designed sectional valve from 1 to 8 sections for open and closed center hydralic systems.

Spool function options:O,P,Y,A and etc.

Lever side control options:manual,pneumatic,electric and pneumatic control,hadralic and electric control,hydralic control and remote control.

Compact structure, modular design, easy to integrate.

DCV20 series Monoblock Valve are widely used in hydraulic systems of engineering machinery, sanitation machinery, mining machinery and other machinery.

SPECIFICATIONS:

| Nominal Flow | 20 L/min |

| Viscosity Range | 12-75 CST |

| Max.Pressure | 350 bar |

| Internal Leakage | 15cc/min at 160 bar,50℃ |

| Ambient Temp | -40~80℃ |

| Valve structure | Sectional Valve |

| Valve surface | Phosphating treating |

| Valve Sections | 8 Sections |

| Rustproof Level | Neutral salt Spray test,48 hours |

If you need more detailed information or have other requirements, please contact us

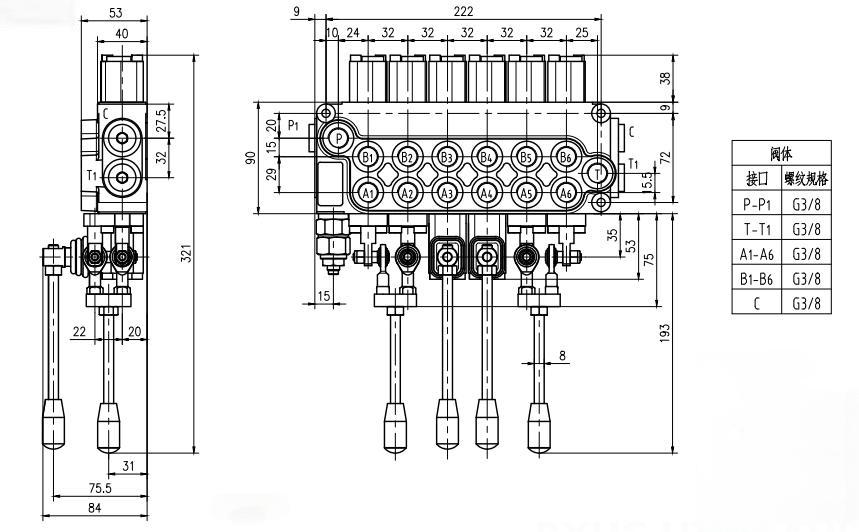

DCV20 SERIES MONOBLOCK VALVE DIMENSIONS DATA:

Application Areas:

Engineering machinery: such as loaders, excavators, cranes, etc., used to control the actions of working devices, such as digging, loading, lifting and other operations.

Sanitation machinery: such as garbage trucks, sweepers, etc., to achieve garbage loading and unloading, compression and motion control of cleaning devices.

Agricultural machinery: such as tractors, harvesters, etc., can control the lifting and turning of agricultural tools to improve agricultural production efficiency.

Other fields: It can also be used in the hydraulic systems of drilling machinery, industrial vehicles and other equipment to achieve various hydraulic control functions.

Installation and Maintenance:

Installation: During installation, attention should be paid to the installation direction of the valve and the correctness of the oil port connection to ensure smooth oil flow; at the same time, the installation position should be easy to operate and repair.

Maintenance: Regularly check the sealing performance of the valve to prevent oil leakage; clean the hydraulic oil filter to maintain the cleanliness of the hydraulic oil to prevent impurities from entering the valve and causing valve core jamming and other faults; check the wear of the valve core, and replace it in time if it is severely worn.

FAQ:

What are the categories of multi-way valves?

There are two types of multi-way reversing valves: integral type and segmented type; according to the oil circuit connection method, multi-way valves can be divided into parallel, series, series-parallel and composite oil circuits; there are two unloading methods: mid-position unloading and safety valve unloading.