DCV200 Series Sectional Valve are a high-performance product with a wide range of applications in construction machinery , sanitation machinery and drilling machinery.DCV200 Series Sectional Valves are characterized hy high working pressure , compact structure , good opening and closing characteristics of safety and overload valves , and good versatility.

DCV200 Series Sectional Directional Valve

MODEL:DCV200 Sectional Directional Valve

APPLICATIONS & FEATURES:

DCV200 Series Sectional Valves are simple,compact and heavy duty designed sectional valve from 1 to 12 sections for open and closed center hydralic systems.

Spool function options:O,P,Y,A and etc.

Lever side control options:manual,pneumatic,electric and pneumatic control,hadralic and electric control,hydralic control and remote control.

Compact structure, modular design, easy to integrate.

SD8 series Sectional Valve are widely used in hydraulic systems of engineering machinery, sanitation machinery, mining machinery and other machinery.

SPECIFICATIONS:

| Nominal Flow | 200 L/min |

| Viscosity Range | 12-75 CST |

| Max.Pressure | 350 bar |

| Internal Leakage | 15cc/min at 160 bar,50℃ |

| Ambient Temp | -40~80℃ |

| Valve structure | Sectional Valve |

| Valve surface | Phosphating treating |

| Valve Sections | 1-12 Sections |

| Rustproof Level | Neutral salt Spray test,48 hours |

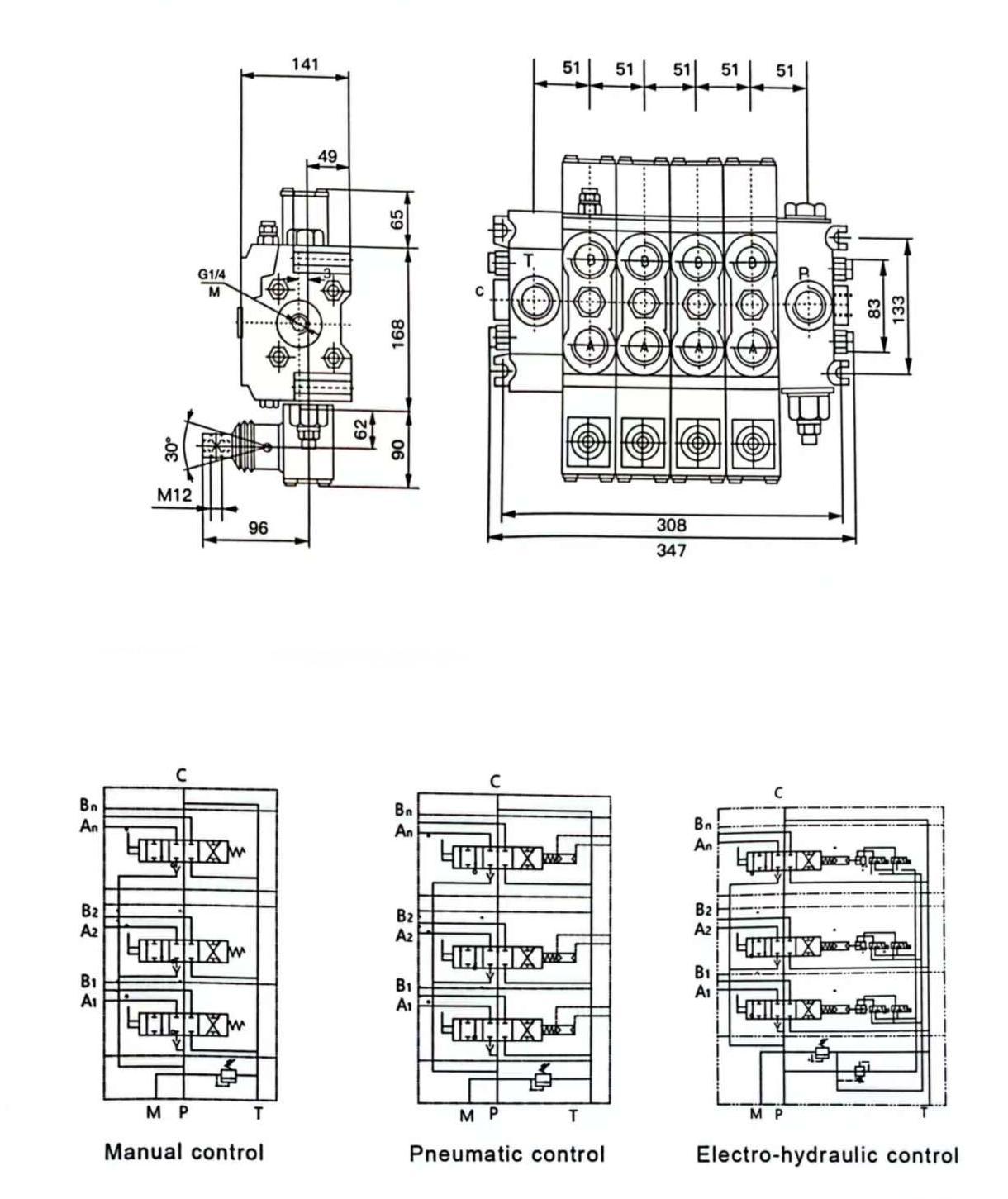

DCV200 SERIES SECTIONAL VALVE DIMENSIONS DATA:

Application Scenario:

Engineering machinery: such as excavators, cranes, forklifts, etc., used to control the actions of actuators such as booms and buckets.

Mining equipment: realize centralized control of multiple actuators in equipment such as drilling rigs and conveyors.

Sanitation machinery: suitable for hydraulic systems such as tow trucks and sanitation vehicles.

Structural Features:

Sliced modular design: It is composed of modules such as the oil inlet valve body, control valve body and oil return valve body. Users can flexibly choose the number of valve slices according to their needs to improve versatility and scalability.

High pressure and large flow: It supports a maximum working pressure of 31.5MPa and a rated flow of up to 200L/min, suitable for high-pressure systems.

Integrated safety protection: Built-in overflow valve and check valve to prevent overload and oil backflow, and enhance system reliability.

Product Benefits:

Versatility: It can realize various complex control functions in the hydraulic system. Through different combinations of sliding valve functions and configurations of additional valves, it can meet the motion control requirements of various actuators, such as reversing, speed regulation, synchronization, etc.

Flexible reliability: Flexible control, multiple combinations and adjustments can be made according to actual working conditions; at the same time, its structural design and manufacturing process ensure the reliability of the product, and it can work stably in various harsh environments and working conditions.

Easy maintenance: The segmented structure makes disassembly, cleaning and maintenance easier. When a reversing valve unit or component fails, only the corresponding part needs to be replaced, without the need to replace the multi-way valve as a whole, which reduces the maintenance cost and time cost.