DN10 Direct Acting Differential Area Catridge Relief Valve,Used as a pressure limiting device to protect hydraulic circuits.

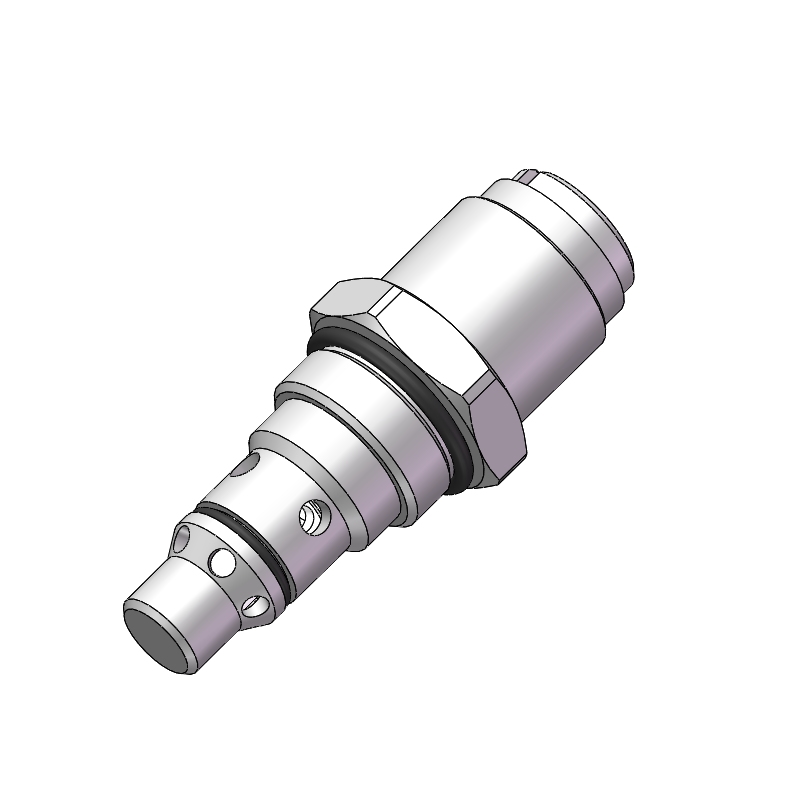

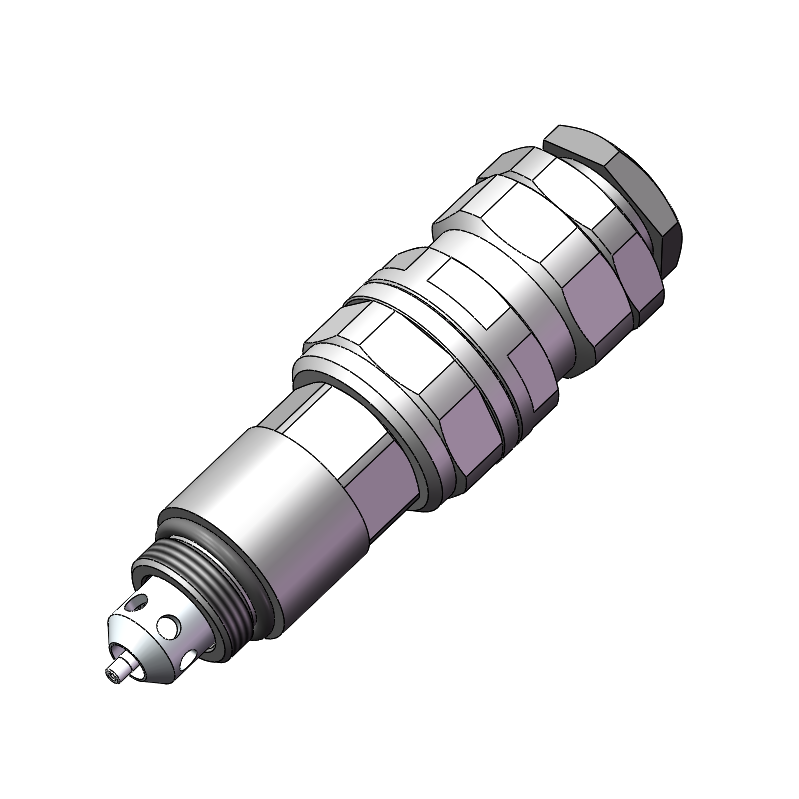

DN10 Direct Acting Differential Area Catridge Relief Valve

JRD10-01

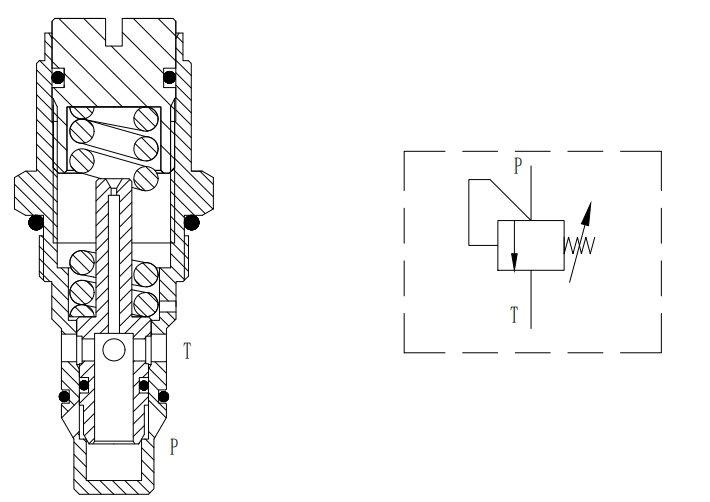

OPERATION:

There are two pressure-bearing surfaces of different areas on the valve core of the Differential Area catridge Relief Valve. The oil inlet pressure acts on these two surfaces, and the generated liquid pressure is balanced with the spring force. When the oil inlet pressure p is low, the spring force is greater than the liquid pressure, the valve core is in a closed state, and the valve port does not overflow. When the oil inlet pressure p rises to a certain value, the liquid pressure overcomes the spring force, the valve core begins to move up, the valve port opens, and the oil overflows back to the oil tank.

FEATURES:

The regulator ensures that the spring will not be compacted.

Miniaturized design: Compared with ordinary direct-acting relief valves, the overall volume is small, which is easy to install and integrate into the hydraulic system. hydraulic system.

The valve core and valve sleeve are hard to handle and durable.

Fast response to pressure change.

Industrial conventional valve hole.

SPECIFICATIONS:

Max.Working Pressure:250bar(3625psi)

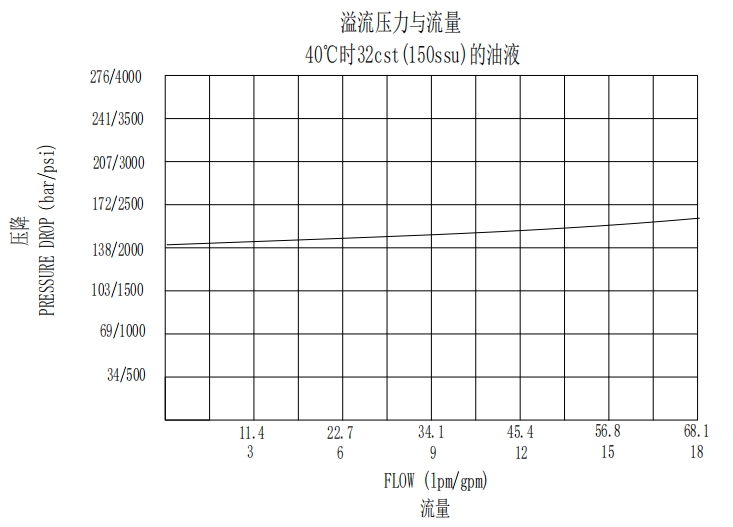

Flow:See performance curve.

Internal leakage:Under the opening pressure of 75%, the leakage is ≤10mL/min.

Opening Pressure Definition:Pressure measurement when the flow reaches 2.5% of the nominal flow.

Clossing Pressure:90% of opening pressure

Filtering Accuracy: 25 μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

Standard Pressure Range: 120 ~ 180 bar (1740 ~ 2610 psi)

CHARACTERISTIC:

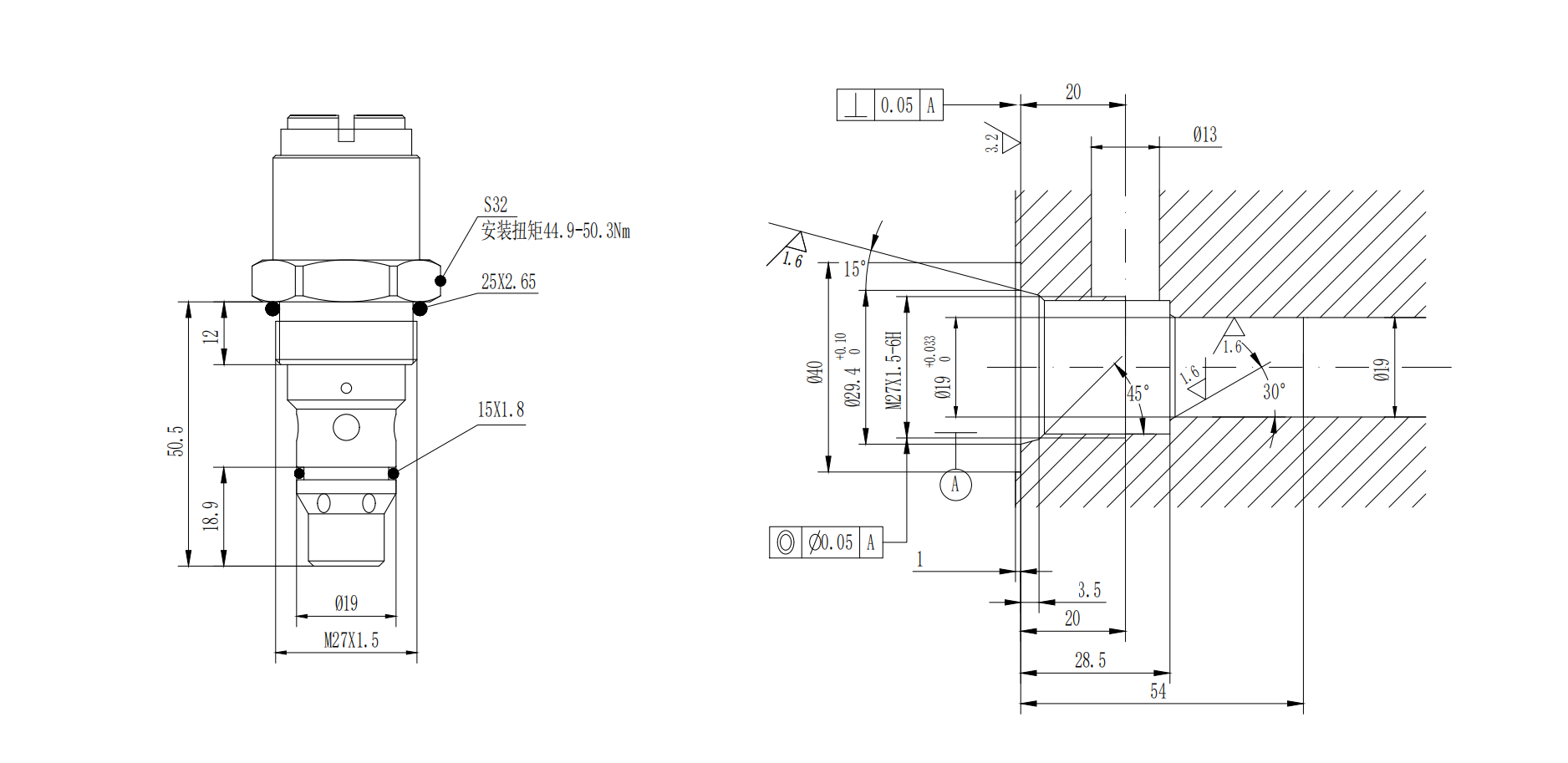

DIMENSIONS:

Application Scenario:

High-pressure and high-flow hydraulic systems: such as hydraulic systems of large engineering machinery, hydraulic presses, metallurgical equipment, etc., these equipment usually require higher pressure and larger flow to drive the actuator to work. The Differential Area catridge Relief Valve can stably control the system pressure under high-pressure and large-flow conditions, and protect the hydraulic system and components from damage by excessive pressure.

Systems with high pressure stability requirements: For example, the hydraulic systems of some precision processing equipment require precise pressure control to ensure processing accuracy; and some hydraulic systems in automated production lines require stable pressure to ensure the accuracy and consistency of each action. The Differential Area catridge Relief Valve can meet the strict requirements of these systems for pressure stability.

The differential relief valve solves the core problems of spring force requirements, pressure fluctuations, cavitation and leakage in high-pressure and high-flow systems through differential area design, flow channel optimization and seal enhancement, and has become a key component in the fields of engineering machinery, ship ballast, oil extraction, etc. Its comprehensive performance indicators (such as pressure stability and energy efficiency) are significantly better than those of direct-acting types, making it the preferred solution for complex hydraulic systems.