Pilot Type One Way Cartridge Relief Valve is equipped in hydraulic unit as pressure reliefvalve and one-way check valve, it is low noise, sensitive pressure response and large flow rate, betterto replace modular valve in a compact desiqned valve block.

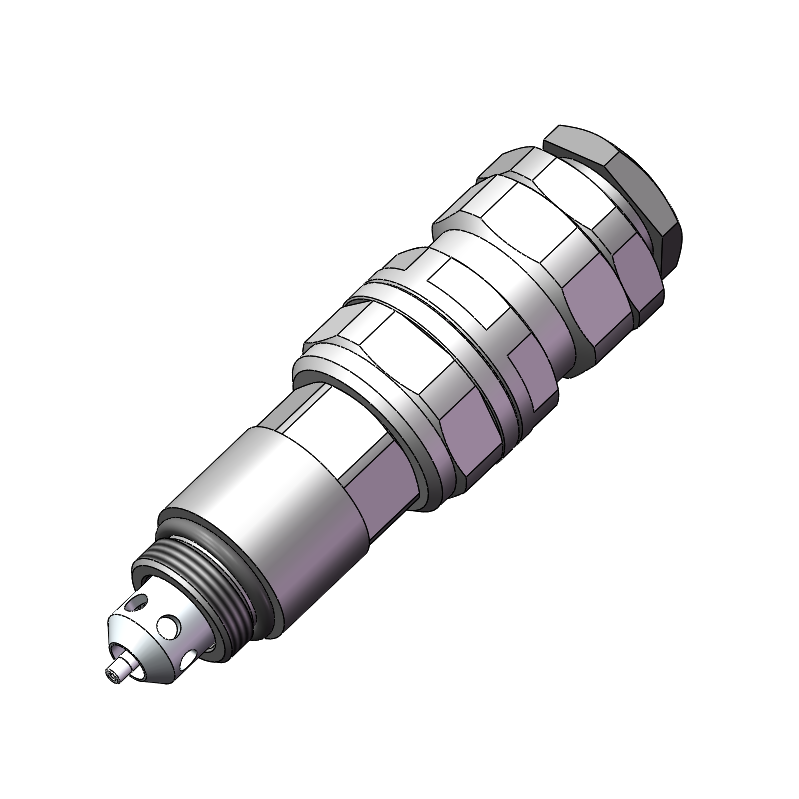

DN25 Pilot Operated Poppet Type Check Cartridge Relief Valve

JRPC25-02

PRODUCT INTRODUCTION:

The Pilot Type One Way Cartridge Relief Valve of pilot cartridge pressure reliefvalve combines pilot operated relief valve and a check valvefunction. The normal working condition of Pilot Type One Way Cartridge Relief Valve is closed (The flow in P port is not allowed flowing to Tport) while the working pressure at T port is below 90% pre-setting pressure of spring. The pilot cartridge pressure reliefvalve starts to flow from the P port to T port (Finally to the oiltank) until the system main pressure reaches to pressing limitedpressure.

The Pilot Type One Way Cartridge Relief Valve with muchsmooth and quiet operation, oil dirt-tolerant, quick to pressureresponse and easily adjustment.

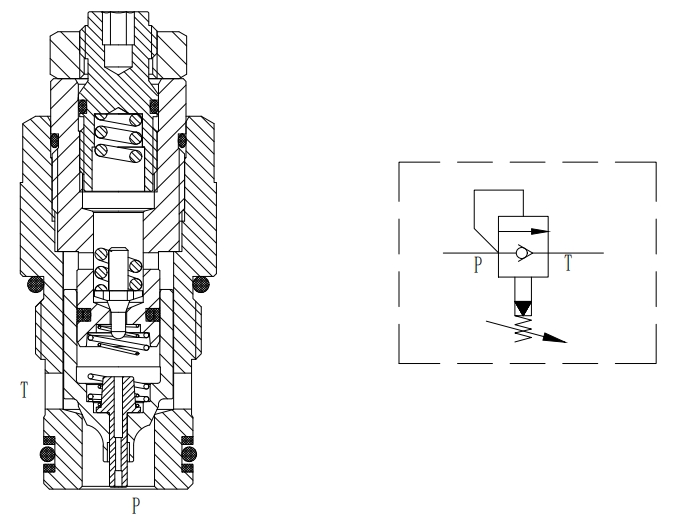

OPERATION:

When the pressure at the P-port does not reach 90% of the set pressure of the spring, P-to-T is blocked; when it exceeds 90% and the pressure continues to rise, P-to-T begins to overflow to the highest set pressure of the spring.

FEATURES:

The regulator ensures that the spring will not be compacted.

Threaded:M30×1.5

The valve core and valve sleeve are hard to handle and durable.

Industrial conventional valve hole.

Quick to pressureresponse and easily adjustment.

SPECIFICATIONS:

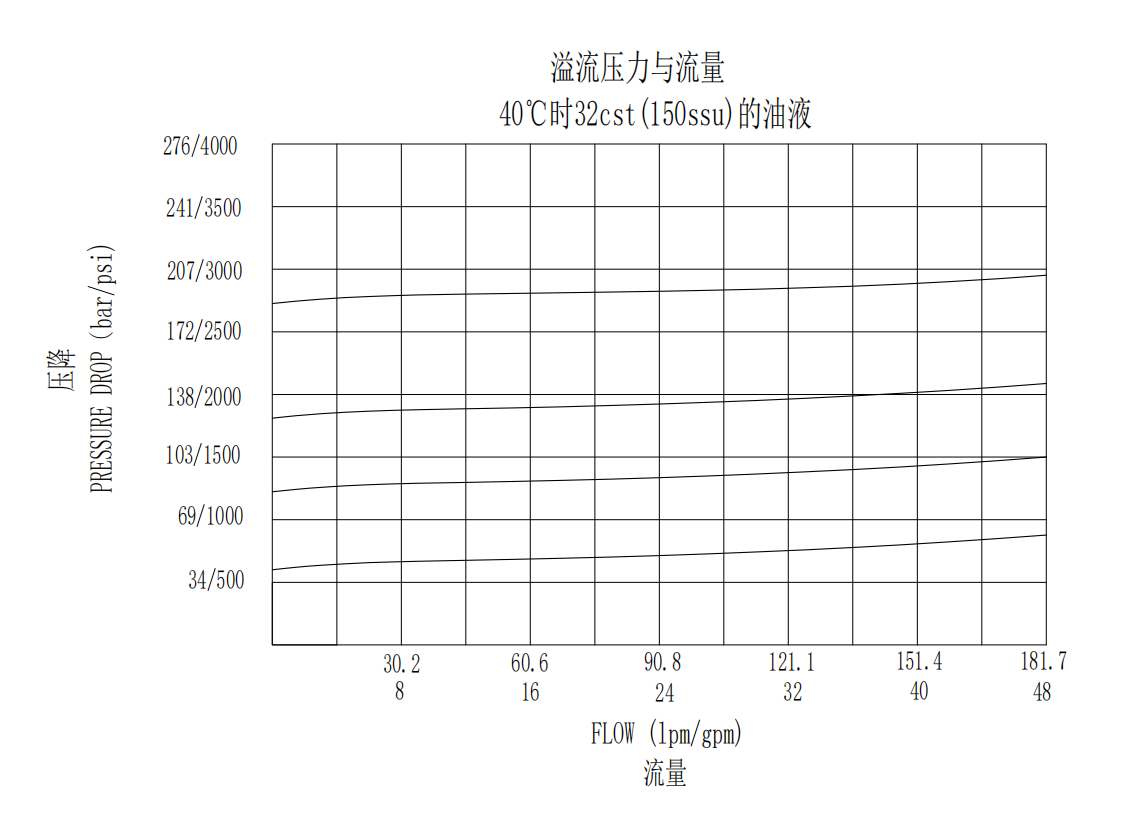

Max.Working Pressure:315bar(4568psi)

Flow:See performance curve.

Internal leakage:Under the opening pressure of 75%, the leakage is ≤3mL/min.

Opening Pressure Definition:Pressure measurement when the flow reaches 2.5% of the nominal flow.

Clossing Pressure:90% of opening pressure

Reverse Opening Pressure: ≤2bar(29psi)

Filtering Accuracy: 25 μ m.

Service Temperature:-40 ~ 120 (NBR),-26 ~ 204 (FKM)

Medium: mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

Standard Pressure Range: 10 ~ 60 bar (145 ~ 870 psi)

55 ~ 130 bar (798 ~ 1885 psi)

110 ~ 210 bar (1595 ~ 3045 psi)

160 ~ 315 bar (2320 ~ 4568 psi)

CHARACTERISTIC:

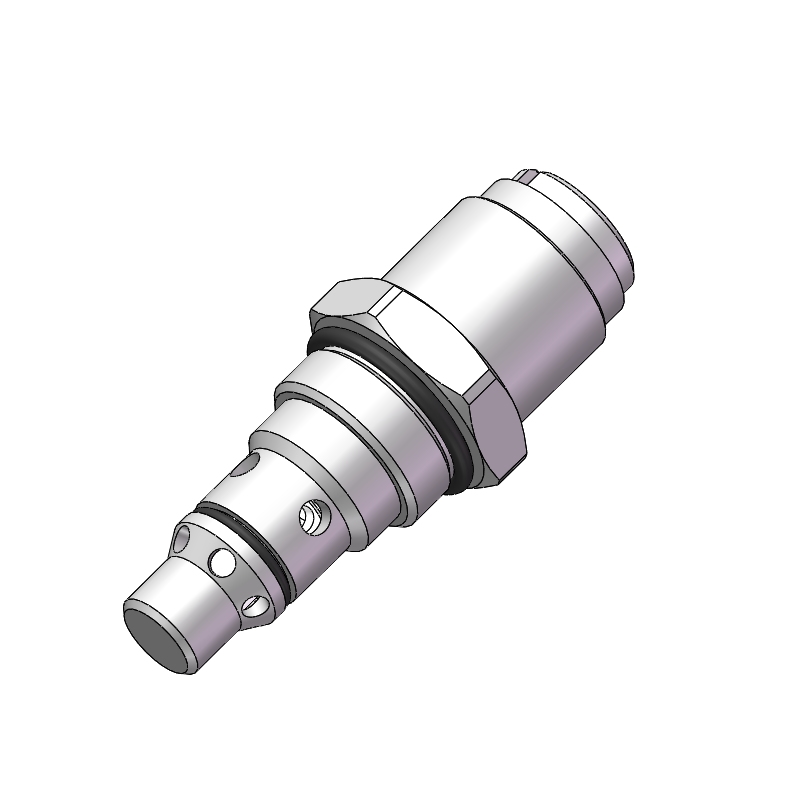

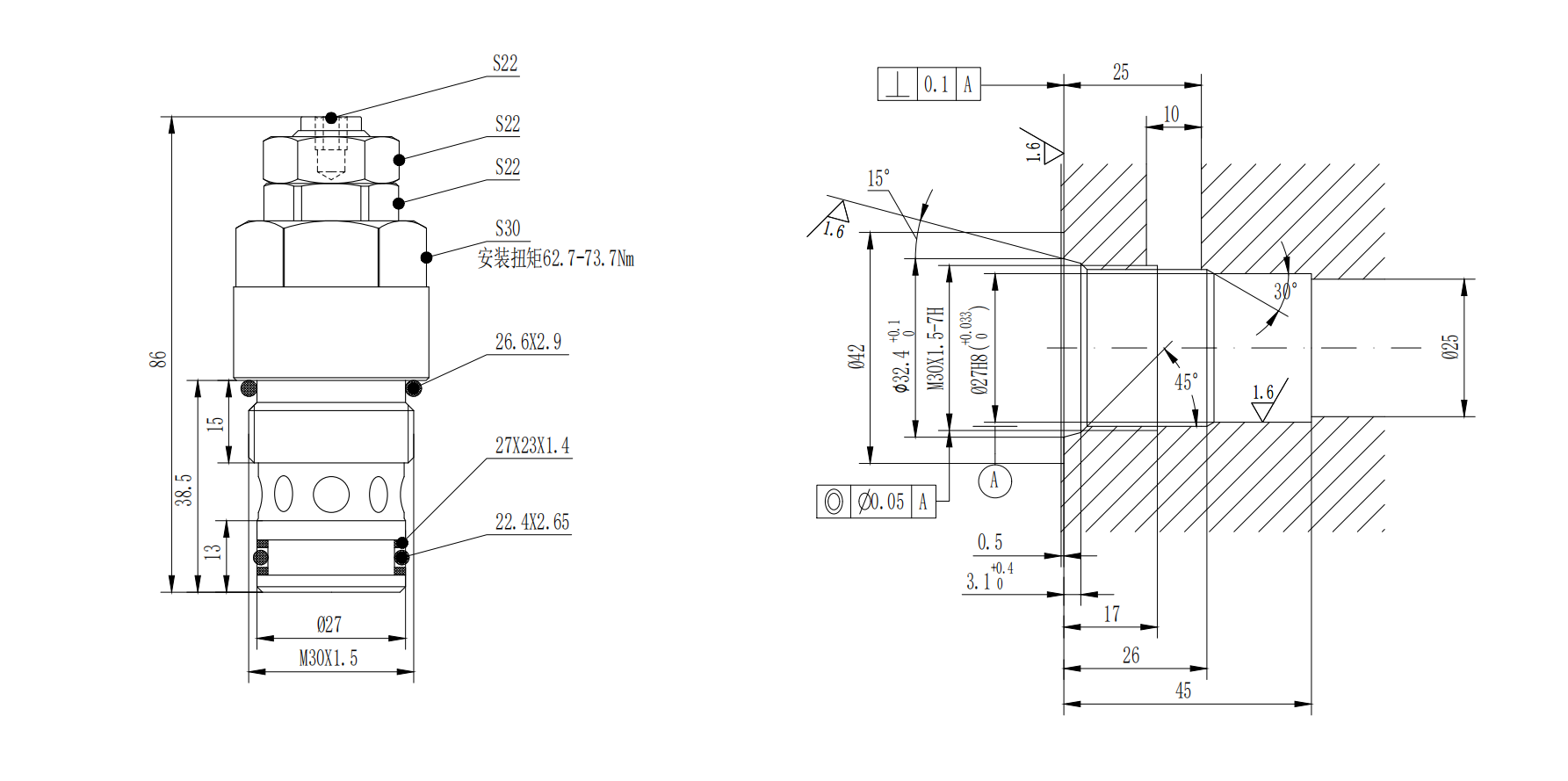

DIMENSIONS:

The core advantage of oil replenishment function:

Cavitation protection: Ensure that the hydraulic pump suction port is always full of oil, avoid cavitation in the pump due to insufficient vacuum, and extend the service life of the pump (can reduce the pump wear rate by more than 30%).

Improved synchronization: In a multi-cylinder synchronous system (such as a ship lifting mechanism), the oil replenishment function can quickly compensate for the difference in leakage of each cylinder and control the synchronization error within ±1mm/m stroke.

Energy-saving characteristics: The oil replenishment path and the overflow circuit are designed independently. There is no need to start the main pump when replenishing oil, which can reduce the system standby power consumption (energy saving of about 15%~20%).