Flow Divider or Combiner Valve. Maintains selected flow divider/combiner ratio regardless of system operating pressure.

DN10 Flow Divider Or Combiner Valve

JFD10-01

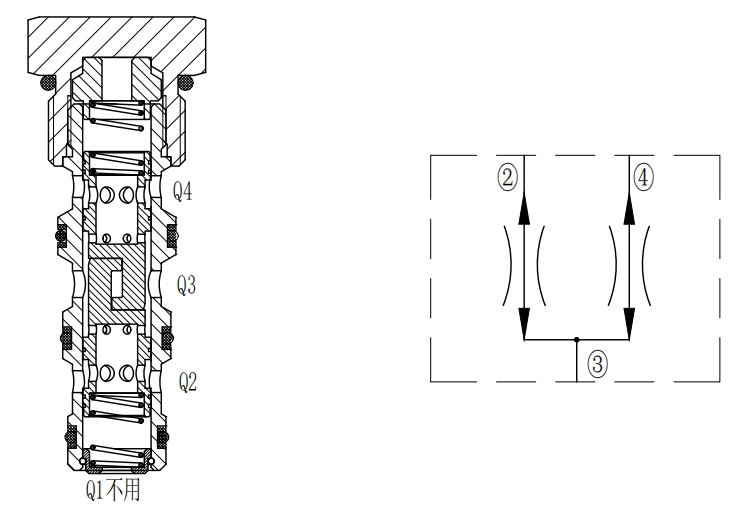

OPERATION OF Flow Divider or Combiner Valve:

Flow diversion principle: When in diversion mode, the input flow flows from port ③ to ports ② and ④ in a specified ratio, and is not affected by the working pressure. The valve uses a pressure compensation mechanism and a flow distribution valve core to accurately distribute the input flow to each output port according to the set ratio, thereby realizing the synchronous diversion operation of multiple actuators.

Flow collection principle: When the oil flows in the opposite direction, the flow of ports ② and ④ will be collected at port ③. During the flow collection process, the valve also uses internal pressure feedback and flow control mechanisms to ensure that the flow of each input port can be evenly collected at the output port, thereby realizing the synchronous flow collection function.

FEATURES:

Synchronization of diversion and collection.

The parts are hard to handle and durable.

Quiet and stable response.

Wide flow range.

Industrial conventional valve hole.

SPECIFICATIONS:

Working Pressure:210bar(3045psi)

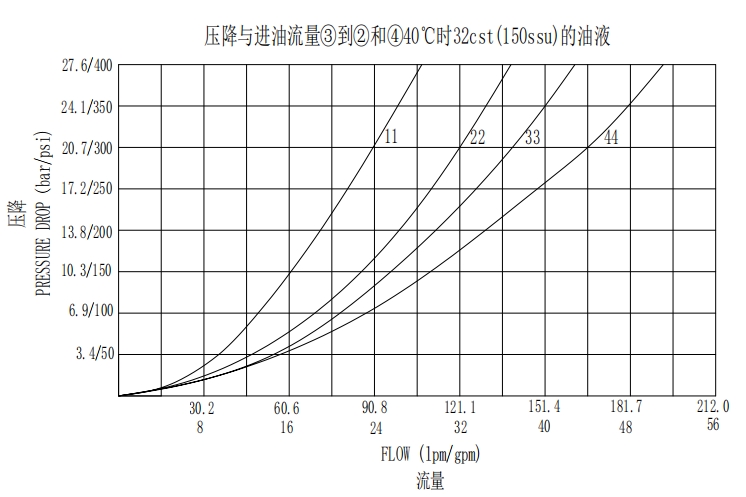

Flow Options:

Input Flow Ratio Model

98.4 lpm 50:50 11

128.7 lpm 50:50 22

167 lpm 50:50 33

197 lpm 50:50 44

Flow Maintenance Accuracy:10% (From 25 -100% of max. rated flow)

Filtering Accuracy: 25 μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

CHARACTERISTIC:

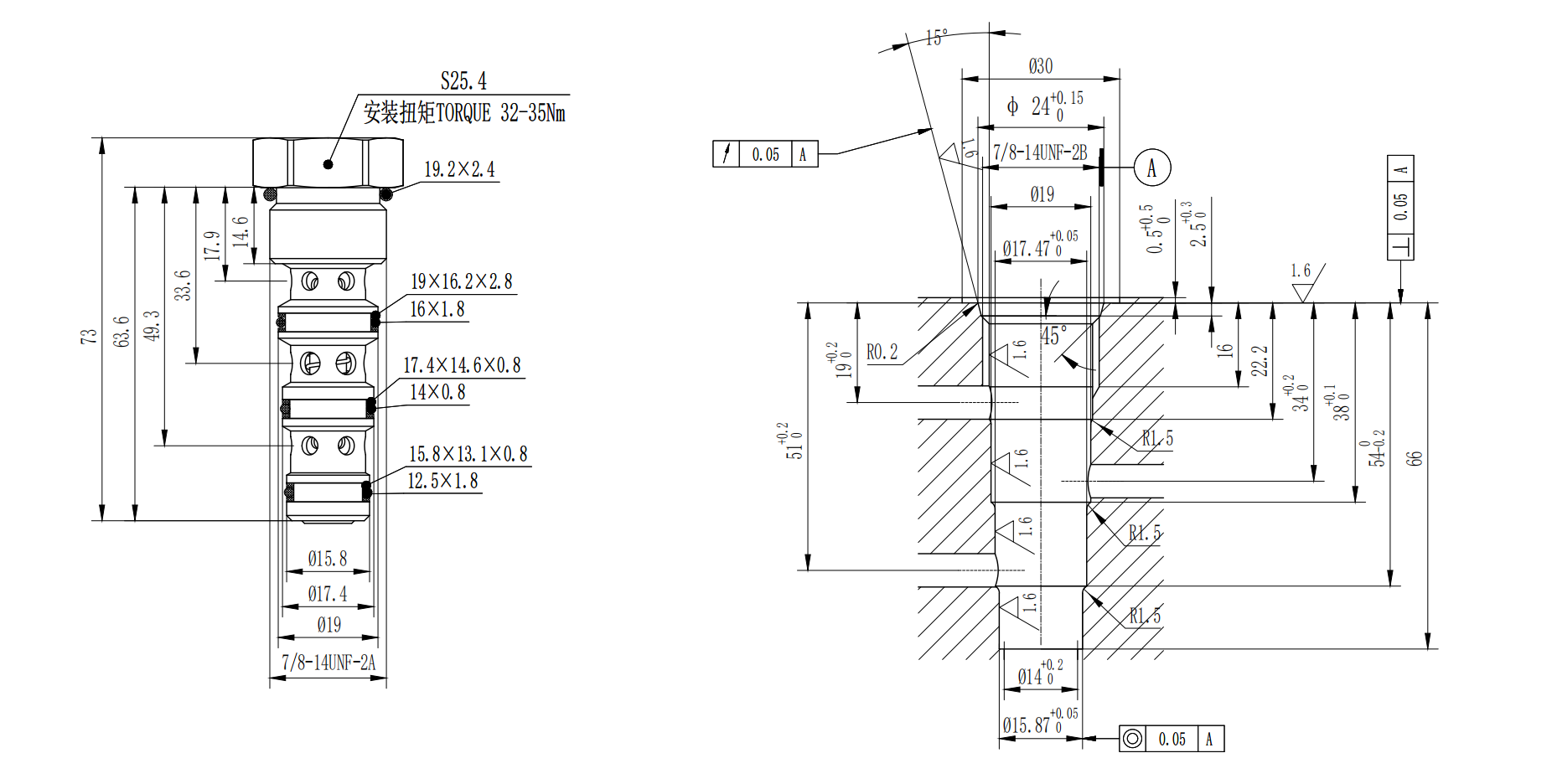

DIMENSIONS:

Application Areas Of Flow Divider or Combiner Valve:

Engineering machinery: such as the synchronous extension and retraction of multiple boom cylinders of cranes and the coordinated operation of multiple working device cylinders of excavators, which can ensure the smooth and coordinated movement of engineering machinery and improve work efficiency and safety.

Metallurgical equipment: used to control the synchronous movement of the roller lifting cylinder of the rolling mill and the crystallizer vibration cylinder of the continuous casting machine to ensure the stability of the steel production process and product quality.

Automobile manufacturing: It plays an important role in various hydraulic equipment on the automobile production line, such as the synchronous control of body welding fixtures and the motion control of automobile parts processing equipment, which helps to improve the degree of automation and product consistency of production.

Shipbuilding industry: It can be applied to the hydraulic system of the ship's steering gear and the synchronous control of multiple cylinders of the ship's cargo crane to ensure the reliable operation of ship equipment and the accuracy of operation.