The Needle Restrictor Free Reverse Flow Control Valve is a compact fluid control element that integrates the functions of a one-way valve and a throttle valve. It is designed specifically for liquid systems and is suitable for scenarios where space is limited and stable one-way flow control is required.

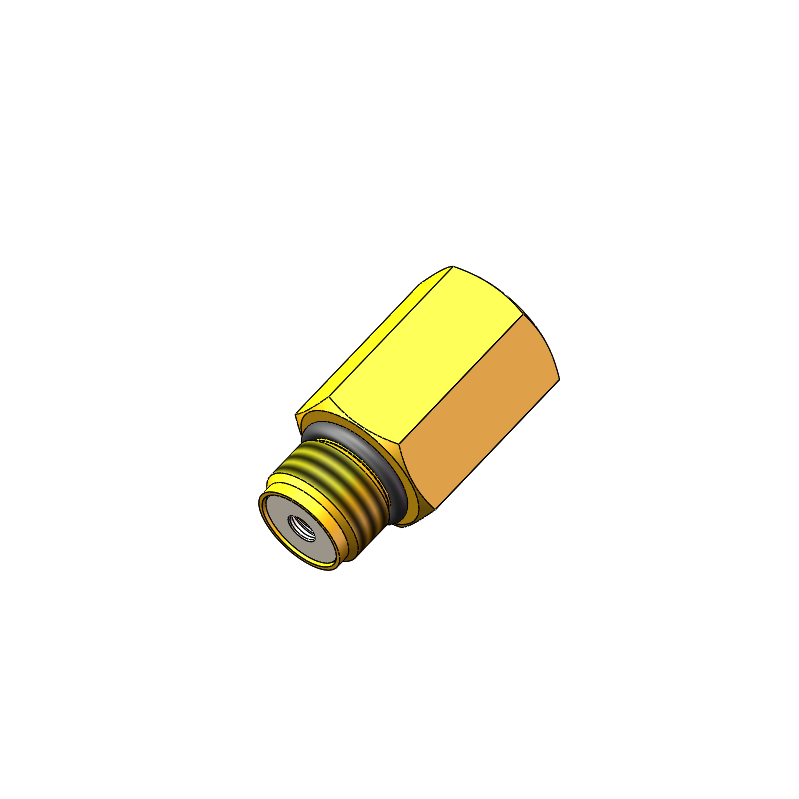

DN10 Needle Restrictor Free Reverse Flow Control Valve

JCN10-01

Product introduction:

The Needle Restrictor Free Reverse Flow Control Valve is a compact fluid control element that integrates the functions of a one-way valve and a throttle valve. It is designed specifically for liquid systems and is suitable for scenarios where space is limited and stable one-way flow control is required.

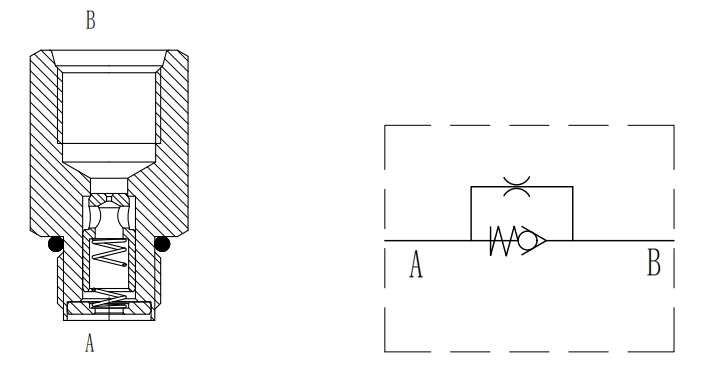

OPERATION:

Forward flow (A→B): The fluid passes through a fixed throttle hole, and the flow rate is determined by the hole size and the pressure difference, achieving stable speed control.

Reverse flow (B→A): The fluid pressure pushes the one-way valve core open and passes directly through the bypass channel with almost no resistance.

FEATURES:

Spool and seat hardened for durability and low leakage.

Small volume

Quickly close in place.

Industrial conventional valve hole.

SPECIFICATIONS:

Max.Working Pressure:315bar(4568psi)

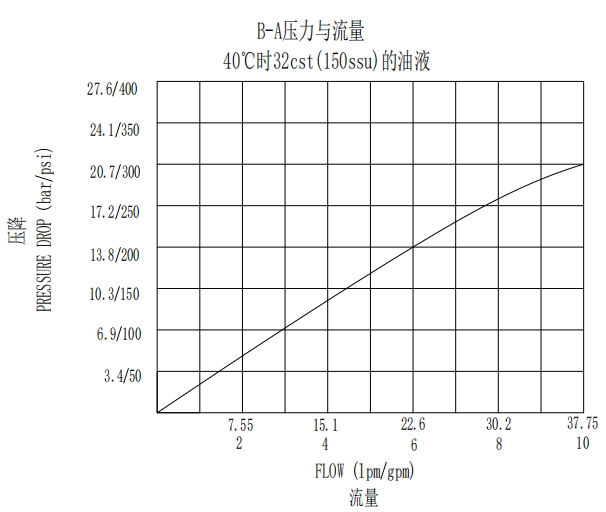

Flow:See performance curve.

Constant Flow: At a pressure of 20bar(290psi):

Orifice Flow

1.0 mm 2300~2750 ml/min

0.9 mm 1830~2130 ml/min

0.8 mm 1420~1680 ml/min

Filtering Accuracy: 25 μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

CHARACTERISTIC:

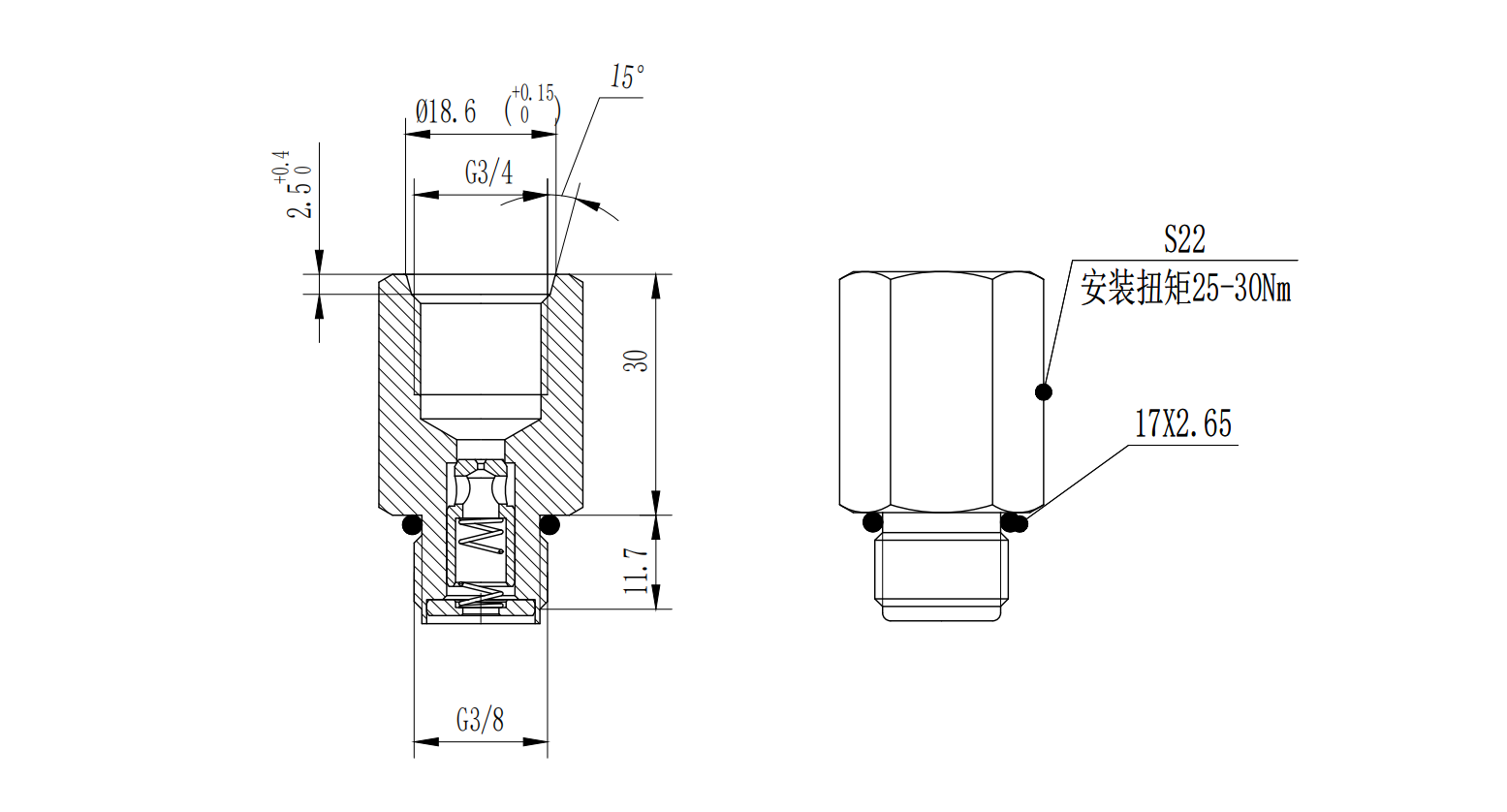

DIMENSIONS:

Application Areas Of Needle Restrictor Free Reverse Flow Control Valve:

Engineering machinery: In the control of the boom, dipper and bucket cylinder of the excavator, it is used to accurately control the movement speed of the cylinder, achieve smooth operation, and improve work efficiency and operation accuracy.

Machine tool equipment: In the hydraulic feed system of CNC machine tools, the feed speed of the tool is accurately controlled to ensure processing accuracy and surface quality.

Automated production line: In the pneumatic control system of material transportation, assembly and other links, the movement speed of the cylinder is controlled to ensure the stability and efficiency of the production process.

The Needle Restrictor Free Reverse Flow Control Valve has the core advantages of high integration, maintenance-free, and high pressure resistance. It is an economical solution for achieving one-way precise speed control in hydraulic/pneumatic systems. It is suitable for industrial scenarios with fixed flow demand, compact space and high reliability requirements (such as engineering machinery and metallurgical equipment). When selecting, it is necessary to focus on aperture matching and system cleanliness management to extend service life.