The Directly with anti-cavitation Poppet Type Relief Valve combines in one compact insert cartridge the typical function of shock relief valve and anticavitation through the check valve.

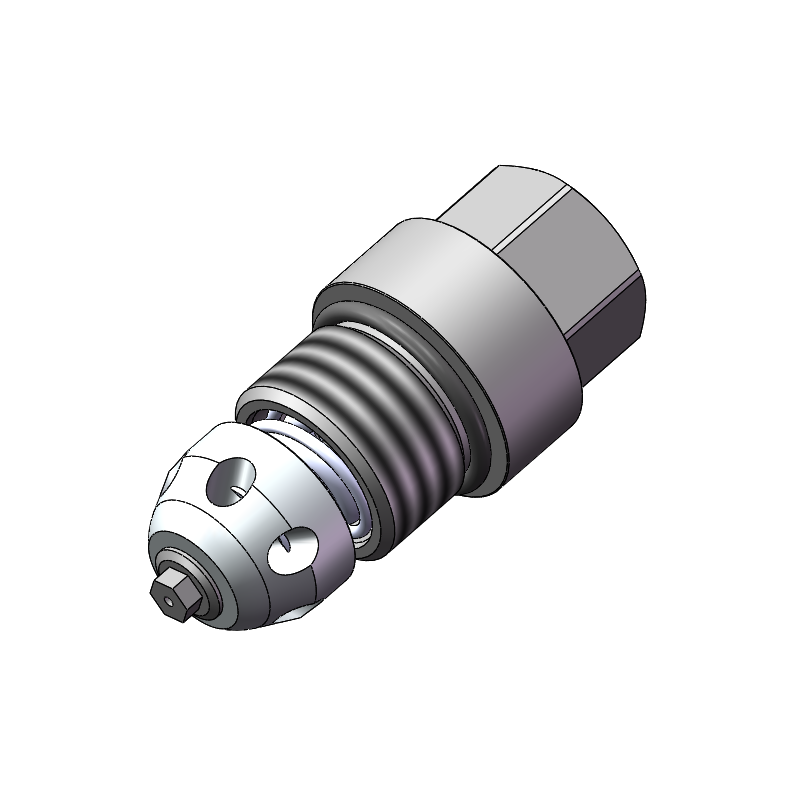

DN20 Direct Acting With Anti-cavitation Poppet Type Relief Valve

JRD20-01

Product Introduction:

The Directly with anti-cavitation Poppet Type Relief Valve with integrated overflow and oil-filling functions. Its direct-acting design directly senses the system pressure through the valve core, has a fast response speed, overflows and stabilizes the pressure when the positive overpressure occurs, and automatically replenishes oil when the reverse low pressure occurs, avoiding air suction or sudden pressure changes.

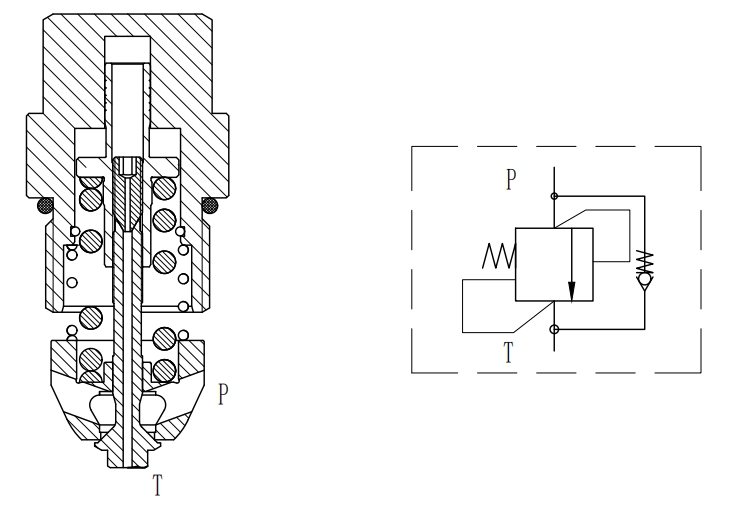

OPERATION:

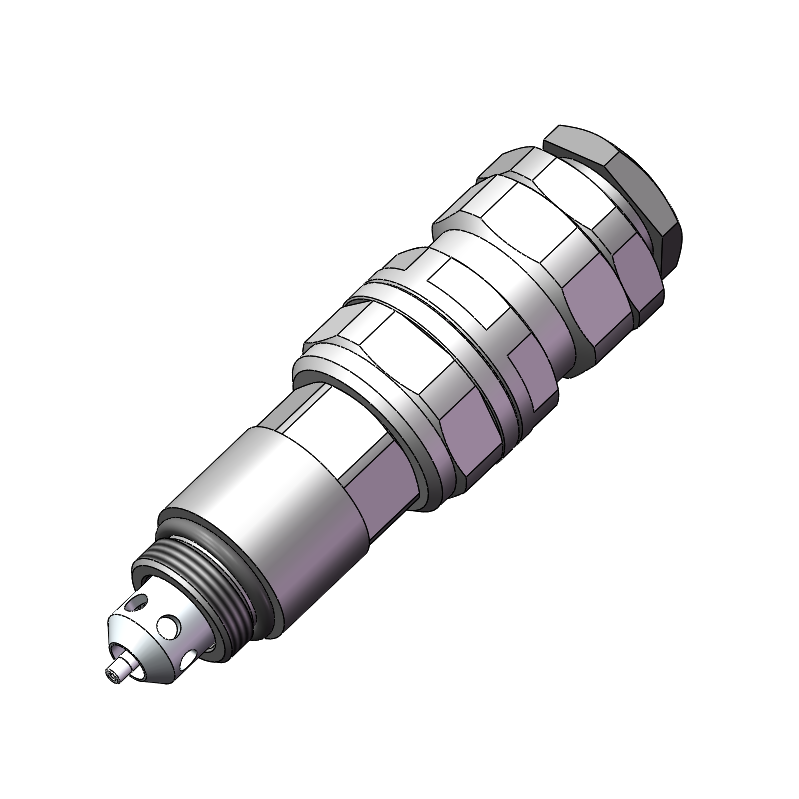

The Directly with anti-cavitation Poppet Type Relief Valve combines in one compact insert cartridge the typical function of shock relief valve and anticavitation through the check valve. In the pressure relief function it’s a side-in nose-exhaust valve, with very low pressure rise thanks to the smart deflector design. When the pressure at the high pressure inlet (P) reaches the valve setting, the valve starts to open to tank (T). In the free reverse flow function a very light bias spring allows for ease of flow passage from nose to side (T to P). High precision machining guarantees quick response to load changes, limited hysteresis and reduced internal and external leakage.

FEATURES:

Double protection: solves the overload pressure relief and oil replenishment needs at the same time, avoiding cavitation and cavitation.

Compact and efficient: the plug-in structure reduces pipeline connections and reduces the risk of leakage, suitable for highly integrated hydraulic systems.

Fast response: the direct-acting overflow design ensures millisecond pressure response, suitable for dynamic load scenarios.

Easy maintenance: the modular design supports quick replacement without disassembling the entire system.

SPECIFICATIONS:

Max.Working Pressure:470bar(6815psi)

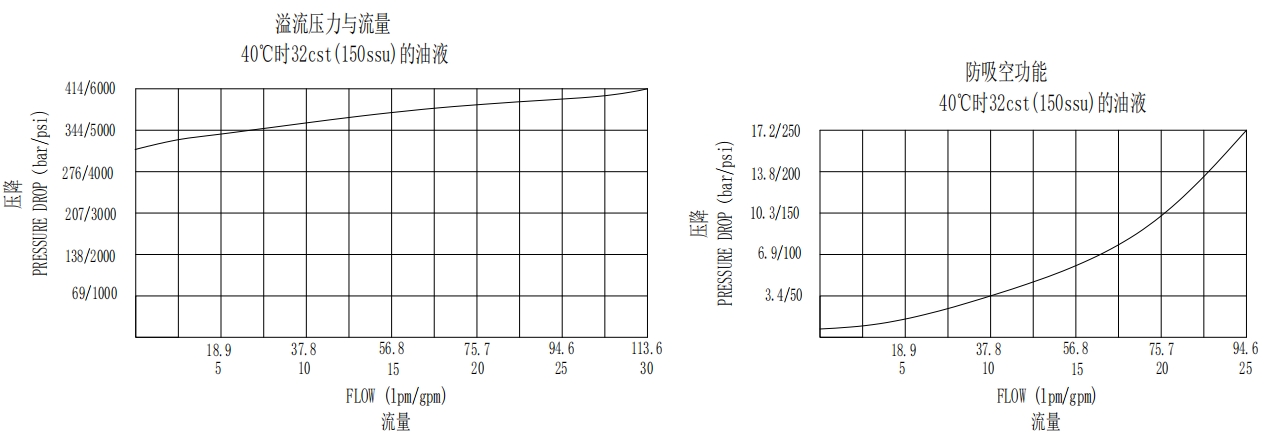

Flow:See performance curve.

Internal leakage:Under the opening pressure of 75%, the leakage is ≤10mL/min.

Opening Pressure Definition:Pressure measurement when the flow reaches 2.5% of the nominal flow.

Clossing Pressure:90% of opening pressure

Filtering Accuracy: 25 μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

Standard Pressure Range: 240 ~ 470 bar (3480 ~ 6815 psi)

CHARACTERISTIC:

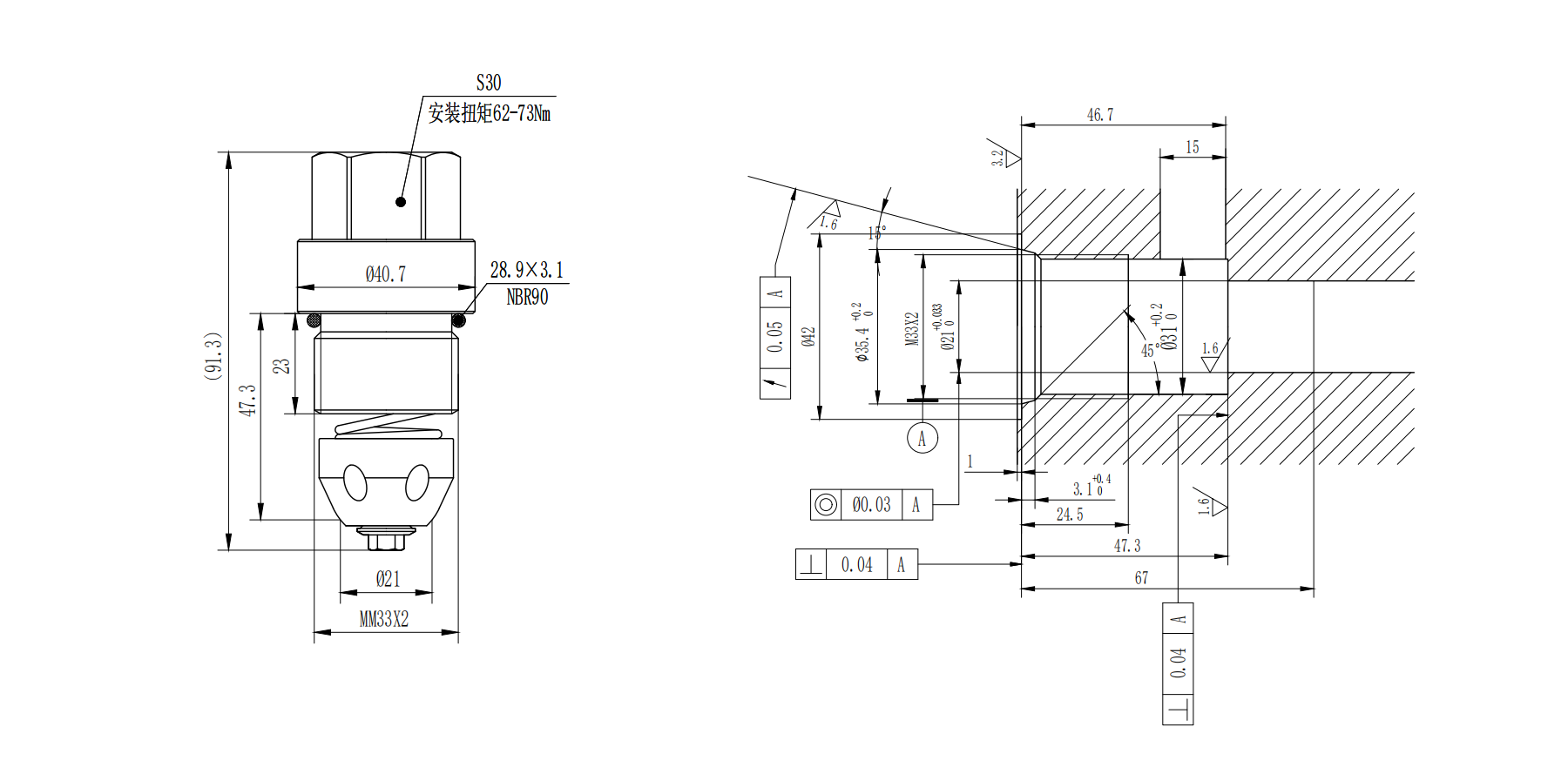

DIMENSIONS:

Typical Application Scenarios:

Engineering machinery: such as overload protection and oil replenishment of hydraulic cylinders of excavators and cranes.

Hydraulic presses and pressure equipment: prevent pressure shocks during stamping, bending and other actions.

Lifting platforms and hydraulic motors: balance system pressure when load changes suddenly.

Injection molding machines and die-casting machines: protect molds and hydraulic pumps from pressure peaks.

FAQ:

What is a poppet valve?

Shape: The valve core of the cone valve type is usually conical (or hemispherical), and cooperates with the conical valve seat on the valve body to form a sealing pair.

Sealing method: The sealing is achieved through the line contact between the conical surface of the valve core and the conical surface of the valve seat, and the sealing line width is extremely narrow (usually < 0.1mm).