The DN20 Pilot Operated Pressure Multiplier Port Check Cartridge Relief Valve are used as pressure limiting devices in hydraulic circuits requiring fast response and low hysteresis.

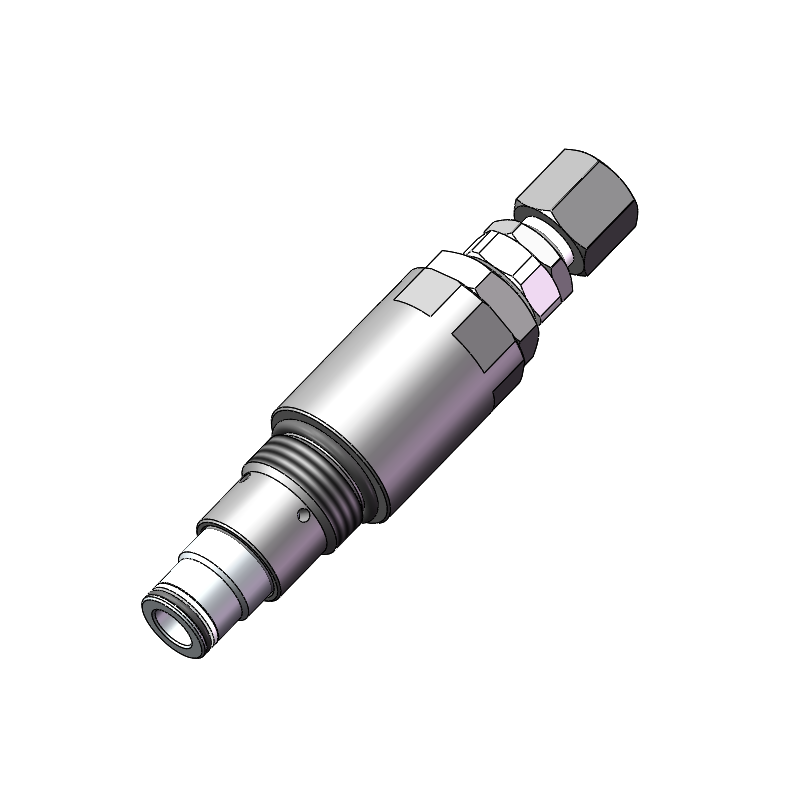

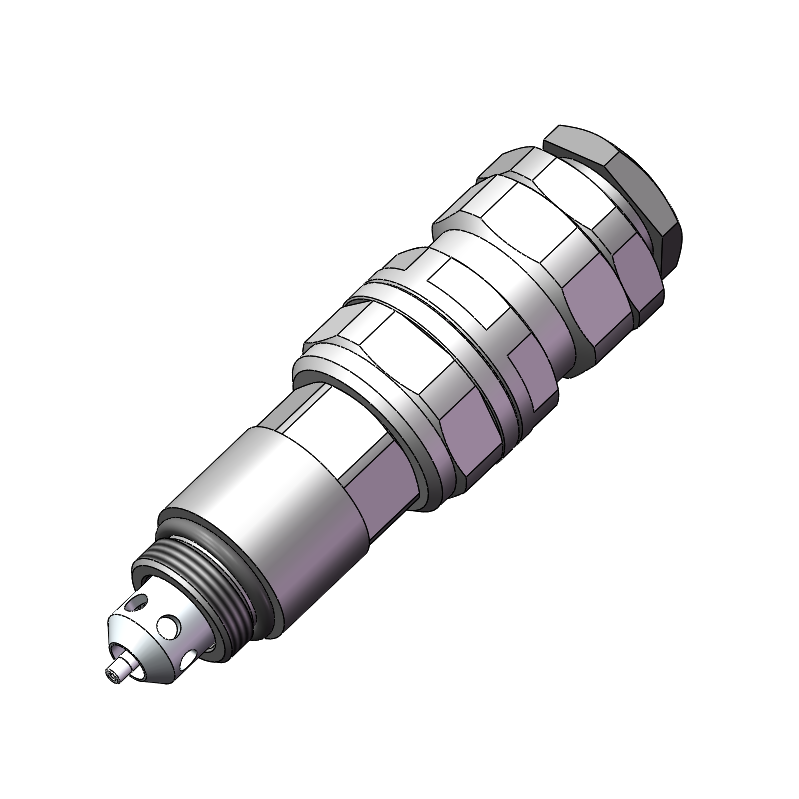

DN20 Pilot Operated Pressure Multiplier Port Check Cartridge Relief Valve

JRPC20-08

Product Introduction:

The Pilot Operated Pressure Multiplier Port Check Cartridge Relief Valve is a hydraulic valve that combines pilot control, oil-filling function and pressure regulation characteristics. It is suitable for scenarios such as mobile hydraulic systems that have high requirements for pressure stability, dynamic response and load adaptability.

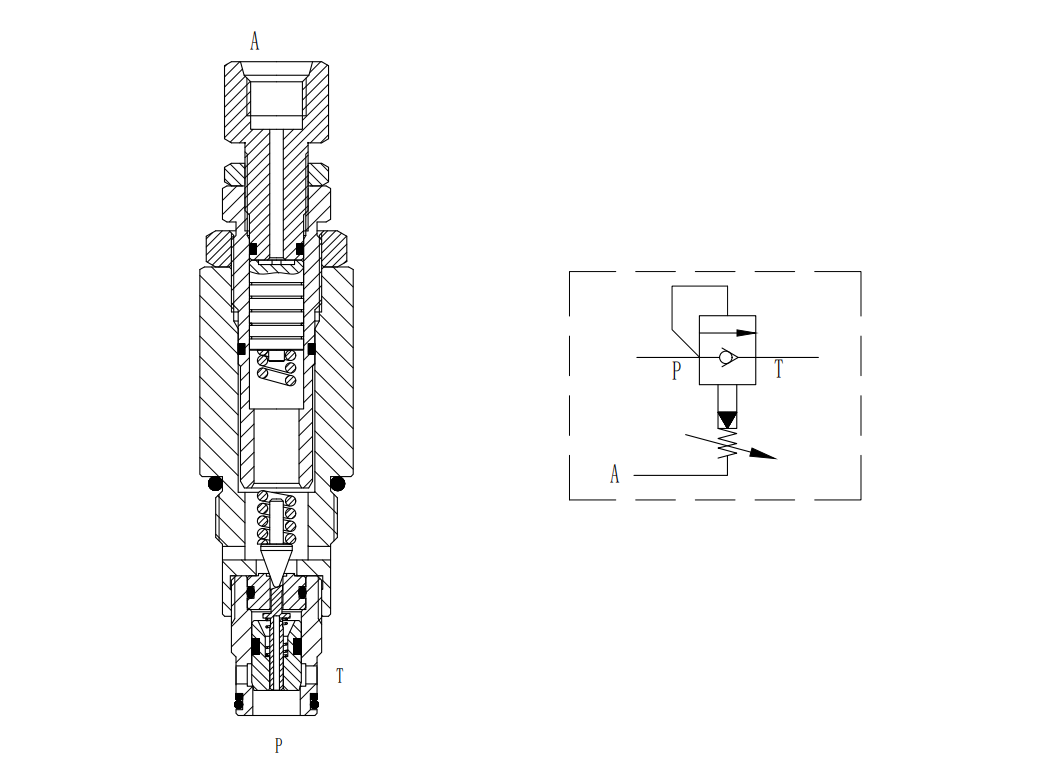

OPERATION:

Normal overflow operation: When the system pressure rises to the set pressure of the pilot valve, the pilot valve opens, and the oil flows to the pilot valve through the damping hole on the main valve core and flows back to the oil tank. Due to the effect of the damping hole, a pressure difference is generated between the upper and lower ends of the main valve core, causing the main valve core to open, and the oil flows from the oil inlet to the oil outlet to achieve overflow, thereby stabilizing the system pressure below the set value of the pilot valve.

Oil replenishment operation: When the pressure of the oil in the system drops due to leakage, movement of the actuator, etc., the oil replenishment device starts to work. The oil replenishment check valve opens under the action of the pressure difference, and the oil enters the system from the oil replenishment source through the oil replenishment pipeline to replenish the amount of oil in the system, maintain the system pressure, and prevent the system from failing to work normally due to too low pressure.

Pressure multiplication operation: When the system requires higher pressure, additional high-pressure oil is introduced through the Pressure multiplier port. The high-pressure oil is superimposed on the pressure in the system at a specific location, so that the system pressure increases, achieving the effect of pressure multiplication, so as to meet the actuator's demand for high pressure under special working conditions.

FEATURES:

The valve core and valve sleeve are hard to handle and durable.

Industrial conventional valve hole.

Respond to pressure changes quickly and smoothly.

SPECIFICATIONS:

Max.Working Pressure:315bar(4568psi)

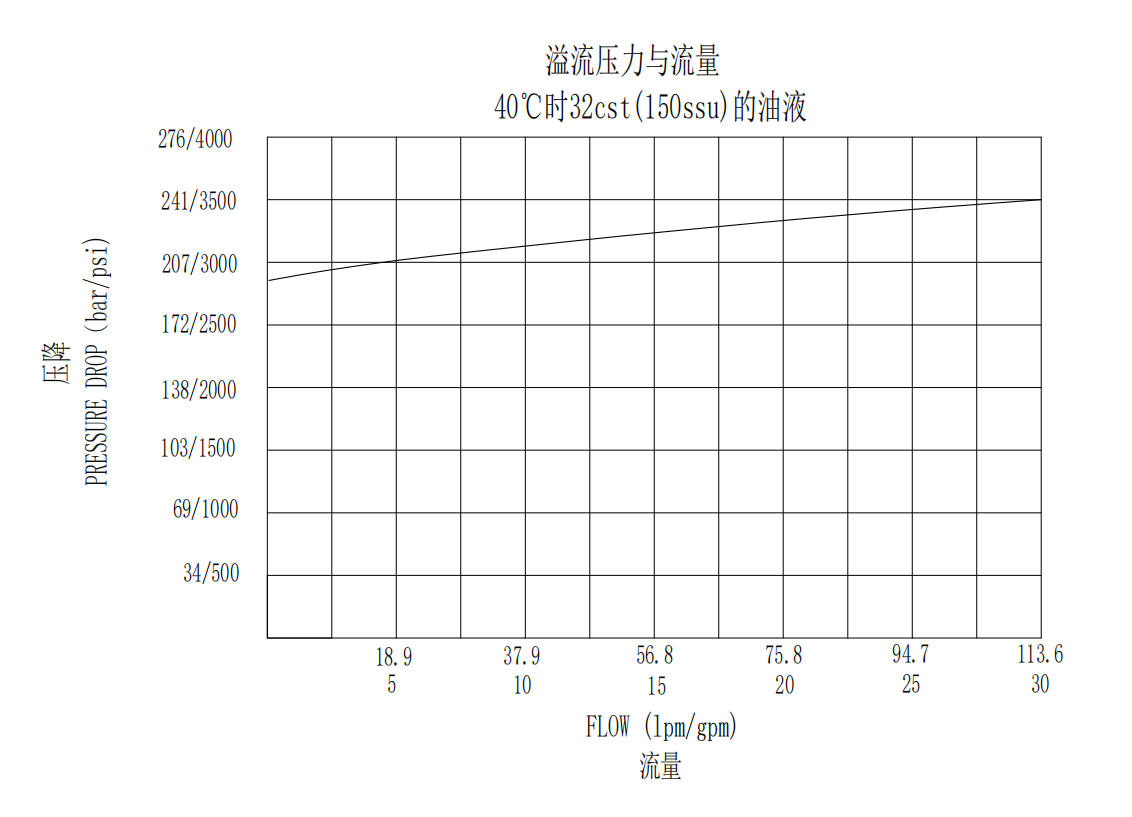

Flow:See performance curve.

Internal leakage:Under the opening pressure of 75%, the leakage is ≤3mL/min.

Opening Pressure Definition:Pressure measurement when the flow reaches 2.5% of the nominal flow.

Clossing Pressure:90% of opening pressure

Reverse Opening Pressure: ≤2bar(29psi)

Filtering Accuracy: 25 μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

Standard Pressure Range: 160 ~ 315 bar (2230 ~ 4568 psi)

CHARACTERISTIC:

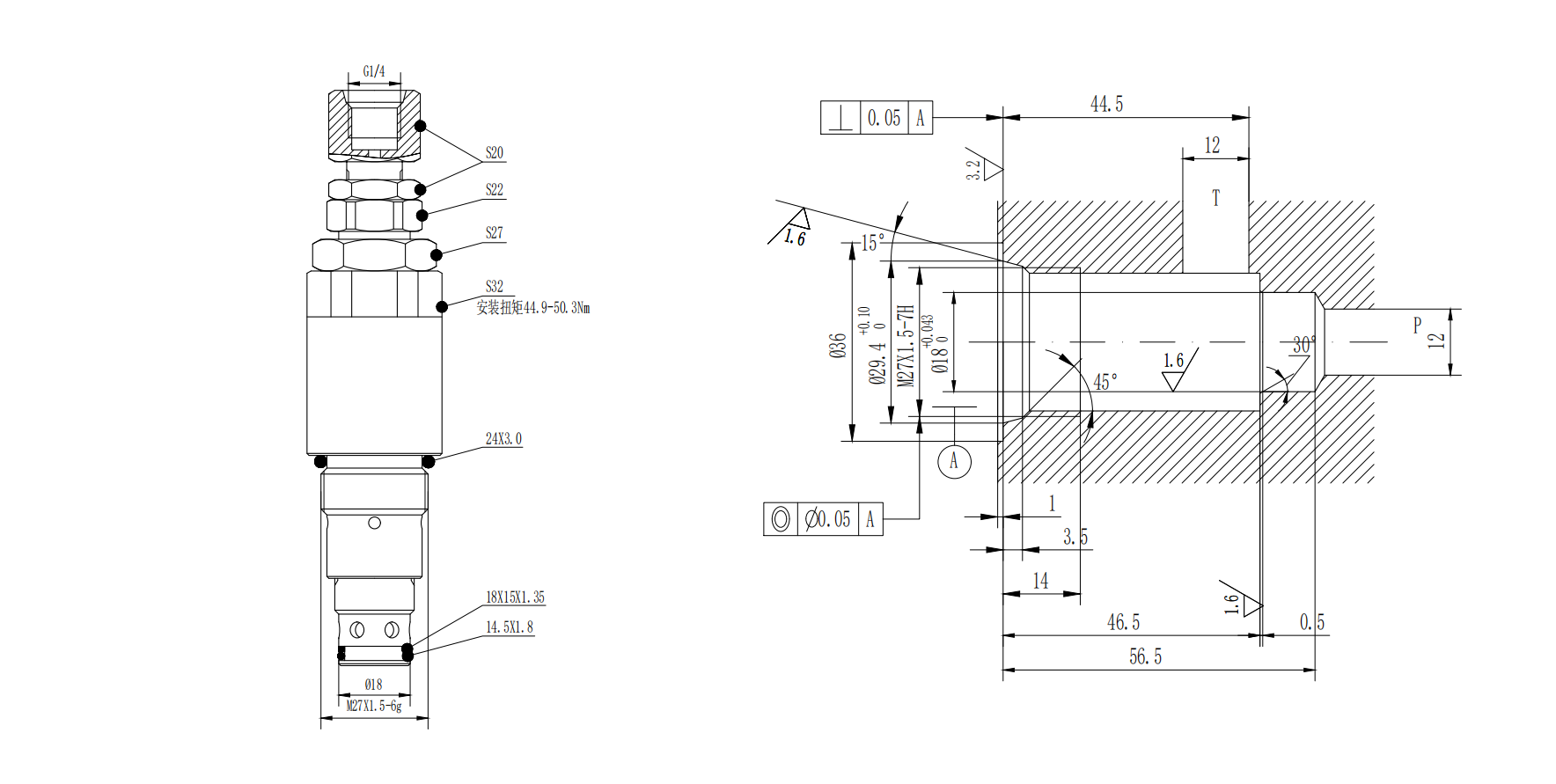

DIMENSIONS:

Application Scenario:

The Pressure multiplier port Cartridge Relief Valve is suitable for systems with severe load fluctuations (such as construction machinery). It can adapt to short-term high-pressure demands without increasing energy power, thereby improving the economy of the equipment.

FAQ:

What are the advantages of a Pressure multiplier port Cartridge Relief Valve compared to an ordinary relief valve?

The Pressure multiplier port Cartridge Relief Valve can conveniently adjust the system pressure through the pressure multiplier port according to actual work needs to adapt to different work tasks and working conditions.