The Pilot Operated Check Relief Valve are used as pressure limiting devices in hydraulic circuits requiring fast response and low hysteresis.

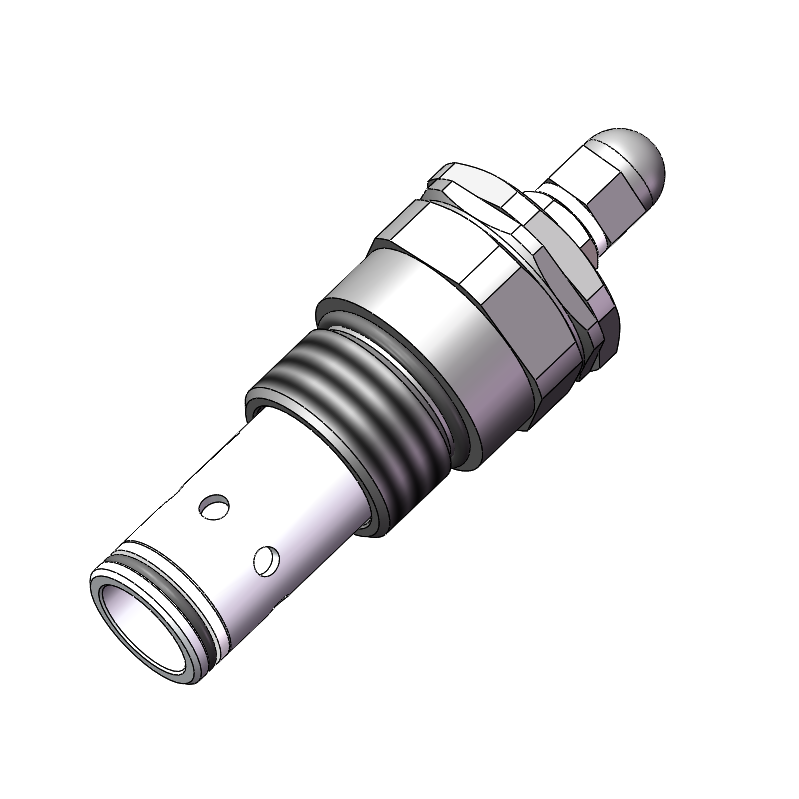

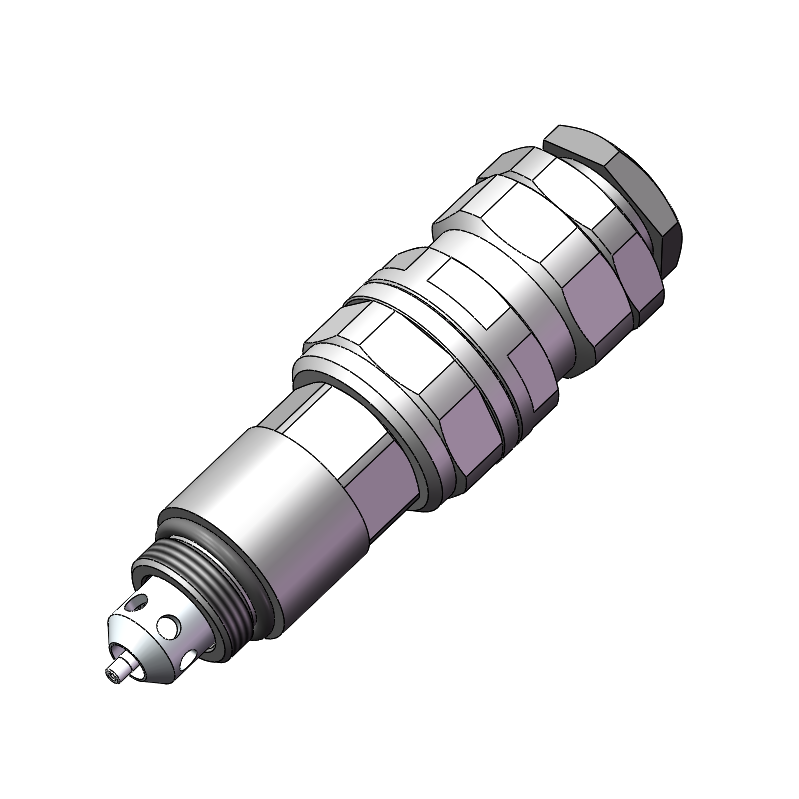

DN32 Pilot Operated Poppet Type Check Cartridge Relief Valve

JRPC32-01

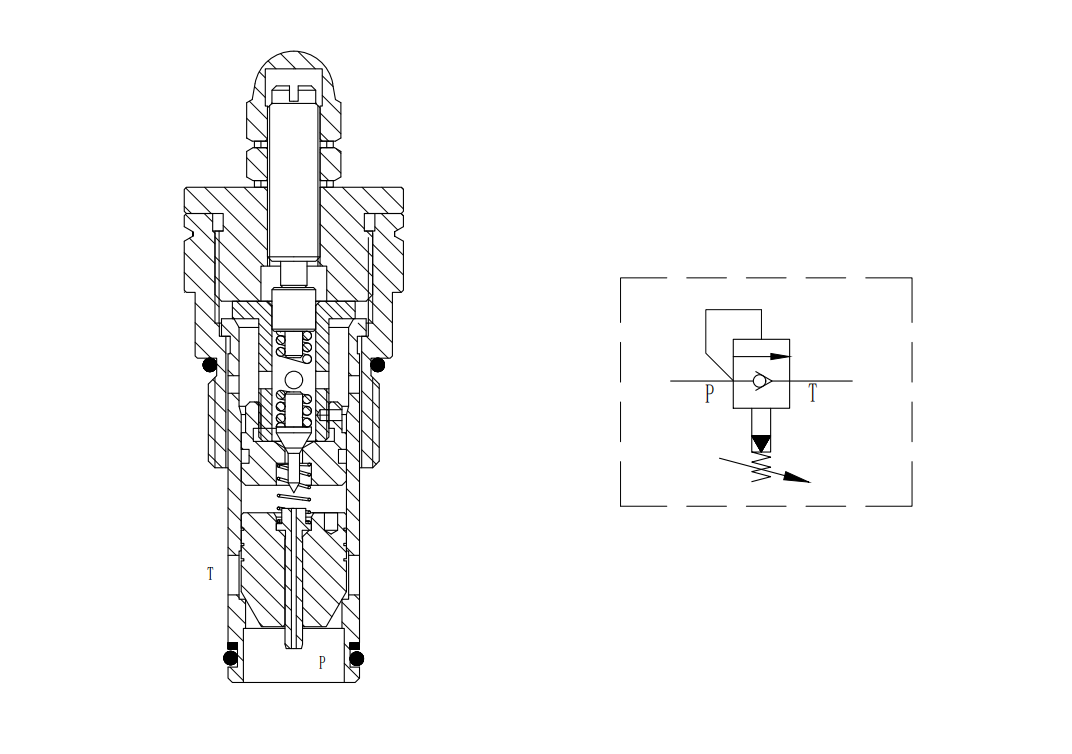

OPERATION:

Normal working state: When the system pressure is lower than the set pressure of the relief valve, the pilot valve is closed, and the main valve core is also in a closed state under the action of the main valve spring. The oil cannot overflow through the relief valve, and the system pressure is established and maintained normally.

Pressure regulation state: When the system pressure rises to the set pressure of the pilot valve, the pilot valve opens, and part of the oil flows back to the oil tank through the pilot valve. Due to the opening of the pilot valve, the pressure in the upper chamber of the main valve core decreases. Under the action of the inlet oil pressure and the main valve spring, the main valve core opens, and the excess oil flows back to the oil tank through the main valve port, so that the system pressure remains near the set value.

Oil replenishment state: When the system pressure drops to the set value of the oil replenishment function due to leakage or other reasons, the oil replenishment channel is opened, and the oil from the external oil source enters the system through the oil replenishment channel, so that the system pressure returns to the normal working range.

FEATURES:

The regulator ensures that the spring will not be compacted.

The valve core and valve sleeve are hard to handle and durable.

Industrial conventional valve hole.

Respond to pressure changes quickly and smoothly.

SPECIFICATIONS:

Max.Working Pressure:315bar(4568psi)

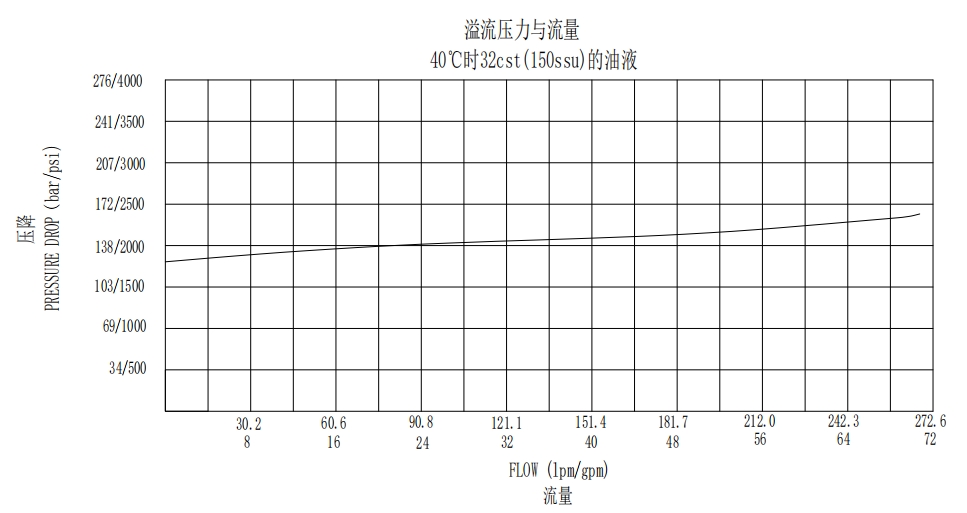

Flow:See performance curve.

Internal leakage:Under the opening pressure of 75%, the leakage is ≤3mL/min.

Opening Pressure Definition:Pressure measurement when the flow reaches 2.5% of the nominal flow.

Clossing Pressure:90% of opening pressure

Reverse Opening Pressure: ≤2bar(29psi)

Filtering Accuracy: 25 μ m.

Service Temperature:-40 ~ 120 (NBR),-26 ~ 204 (FKM)

Medium: mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

Standard Pressure Range: 110 ~ 210 bar (1595 ~3045 psi)

CHARACTERISTIC:

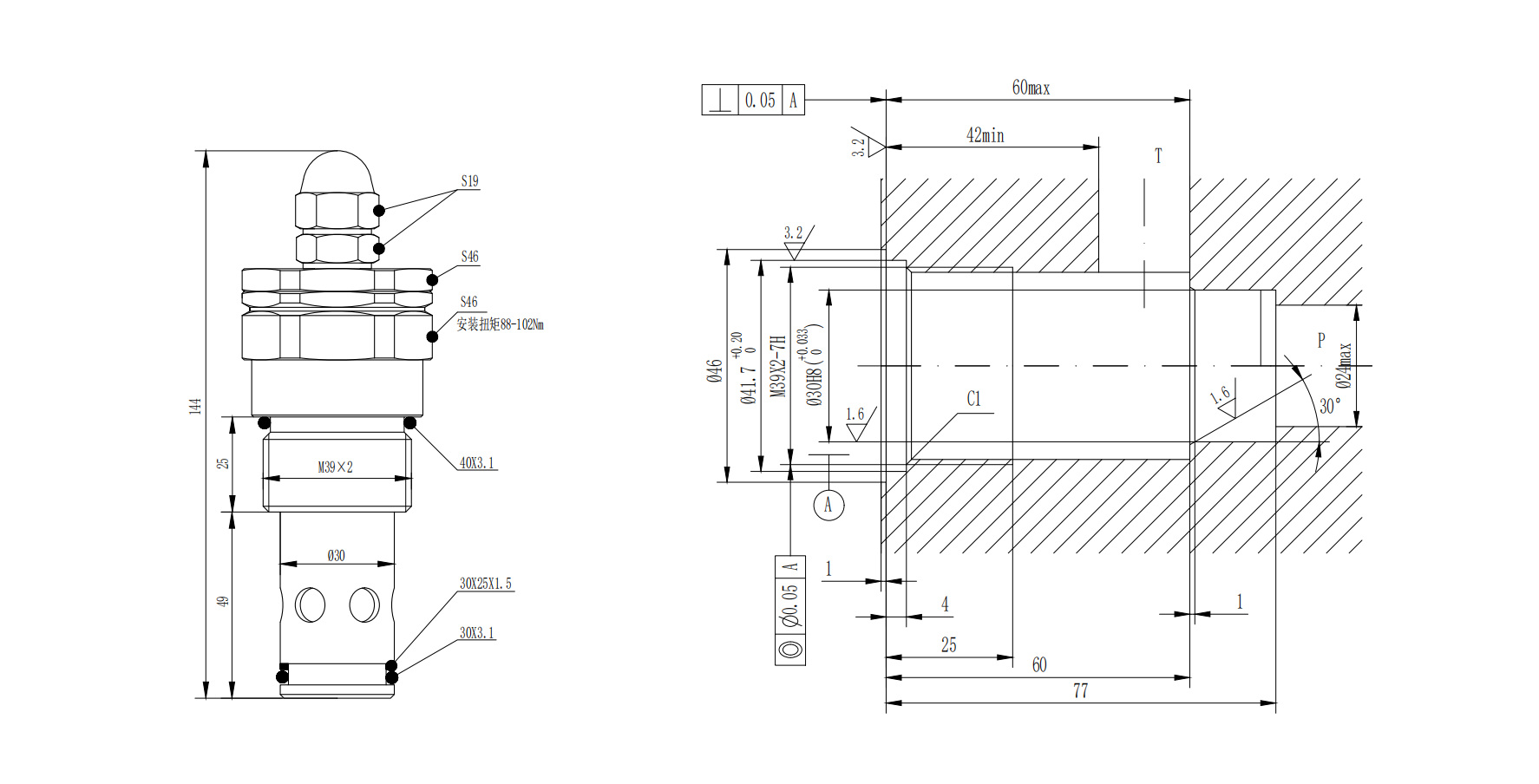

DIMENSIONS OF Pilot Operated Check Relief Valve:

Application Scenario Of Pilot Operated Check Relief Valve:

Engineering machinery: In the hydraulic systems of equipment such as excavators, loaders, cranes, etc., it is necessary to accurately control the pressure and flow of the working device. At the same time, due to the frequent operation of the equipment in harsh working environments, the reliability and oil replenishment function of the relief valve are required to be high. The threaded plug-in structure can meet the equipment's requirements for space and installation convenience.

FAQ:

What are the advantages of Poppet Type core?

Zero leakage: The wire seal structure can achieve complete sealing under high pressure and is suitable for pressure-maintaining circuits.

High-pressure adaptability: The cone surface is evenly stressed and can withstand extremely high pressures.

Strong anti-pollution ability: Compared with the slide valve, particles are not easily stuck between the sealing surfaces (but still need to be filtered).

Simple structure: Few parts, high reliability, and easy maintenance.