A screw-in, Poppet Type, Directly operated Cartridge Relief Valve. It’s typically used to protect hydraulic components from pressure transients.

DN6 Direct Acting Poppet Type Cartridge Relief Valve

JRD06-09

PRODUCT INTRODUCTION:

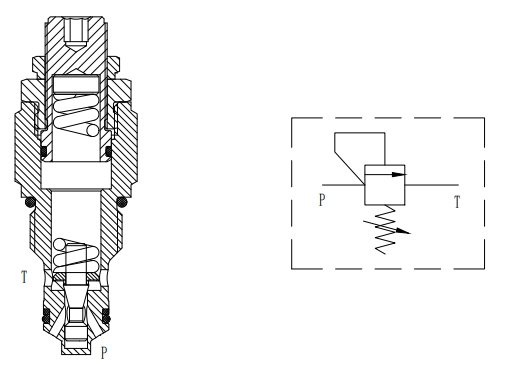

A screw-in, Poppet Type, Directly operated Cartridge Relief Valve. Poppet Type Directly operated Cartridge Relief Valve is typically used to protect hydraulic components from pressure transients. When the pressure at the Inlet (P) reaches the valve setting, the valve starts to open to tank (T) throttling flow to minimize the pressure rise. The innovative geometry of the deflector provides in fact a very low rise rate, and the poppet design guarantees great stability. The cartridge offers quick response to load changes in hydraulic circuits requiring low internal leakage as well as limited hysteresis.

FEATURES:

All external surfaces are zinc plated and corrosion-proof.

All valve parts are made of high strength steel.

Poppet is hardened and ground to guarantee minimal wear and to extend service life.

Adjustment screw cannot be backed out of the valve.

Positive stop prevents springs from going solid.

METRIC cavity.

SPECIFICATIONS:

Max.Working Pressure:285bar(4133psi)

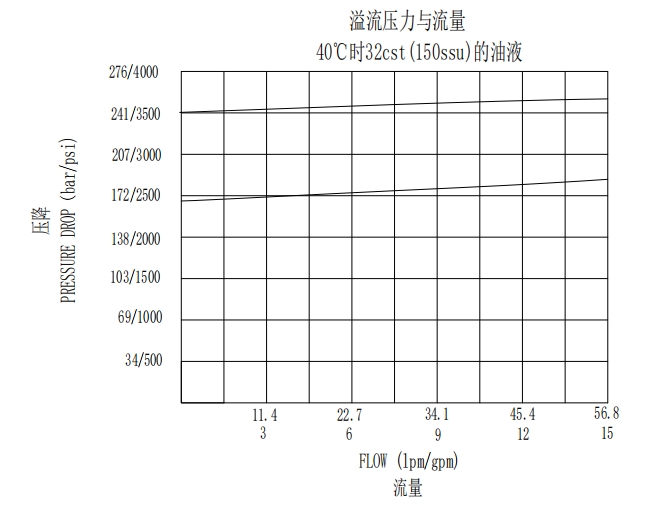

Flow:See performance curve.

Internal leakage:Under the opening pressure of 75%, the leakage is ≤10mL/min.

Opening Pressure Definition:Pressure measurement when the flow reaches 2.5% of the nominal flow.

Clossing Pressure:90% of opening pressure

Filtering Accuracy: 25 μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

Standard Pressure Range: 15 ~ 190 bar (218 ~ 2755 psi)

120 ~ 285 bar (1740 ~ 4133 psi)

CHARACTERISTIC:

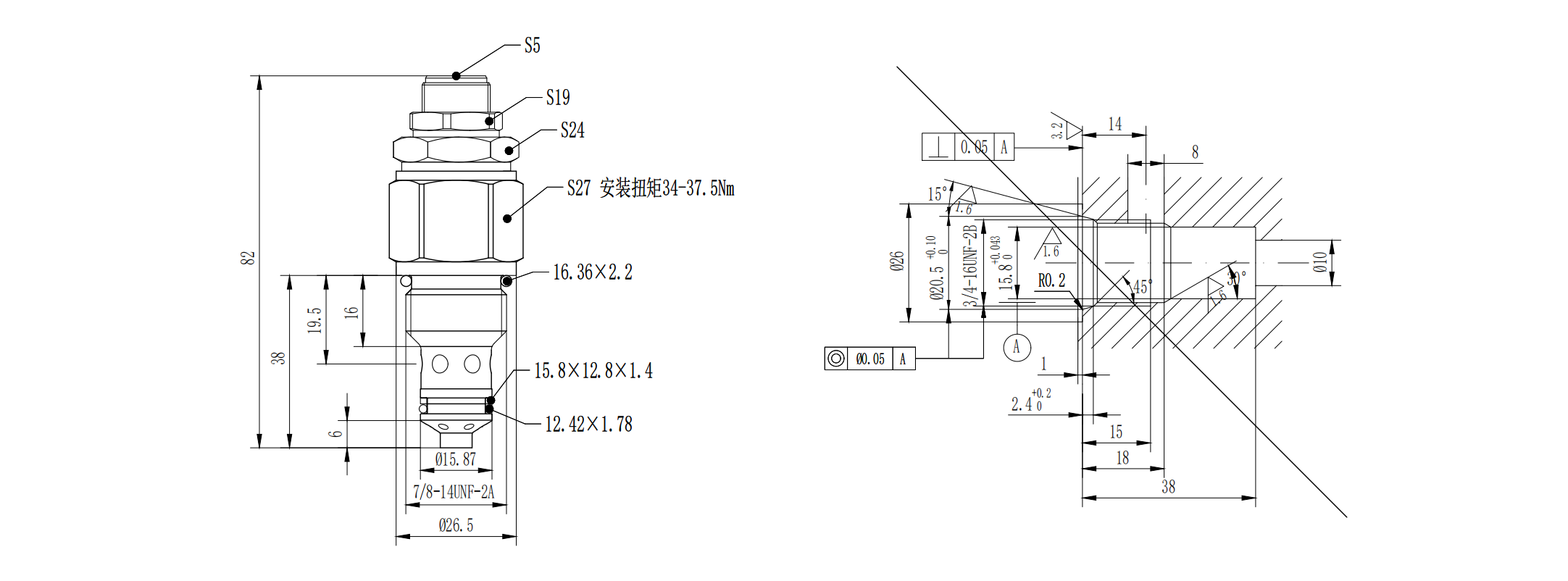

DIMENSIONS:

Application Scenario:

Direct Acting Poppet Type Cartridge Relief Valve are widely used. In engineering machinery, Direct Acting Poppet Type Cartridge Relief Valves are used in excavators, loaders, etc. to control the pressure of the hydraulic circuit of the working device and prevent system overload. In the metallurgical industry, they stabilize the system pressure on rolling mills and continuous casting equipment to ensure production quality and equipment safety. In light industrial machinery, they are used in injection molding machines and papermaking machines to accurately control pressure and improve product quality and production efficiency. In the field of construction machinery, they serve concrete pump trucks and tower cranes to maintain stable system pressure and avoid safety accidents.

FAQ:

Core features of Direct Acting Poppet Type Cartridge Relief Valve:

Direct drive: No pilot control is required, and the structure is simple and compact.

Fast response: It is sensitive when the pressure fluctuates, and is suitable for dynamic pressure control.

Applicable to medium and low pressure: It is commonly used in medium and low pressure systems with pressure ≤40MPa. High pressure scenarios may be limited due to high spring stiffness requirements.

Flow limitation: It is usually used in small flow conditions, and pressure oscillation or noise is easy to occur under large flow conditions.

Poppet Type Poppet Type Poppet Type