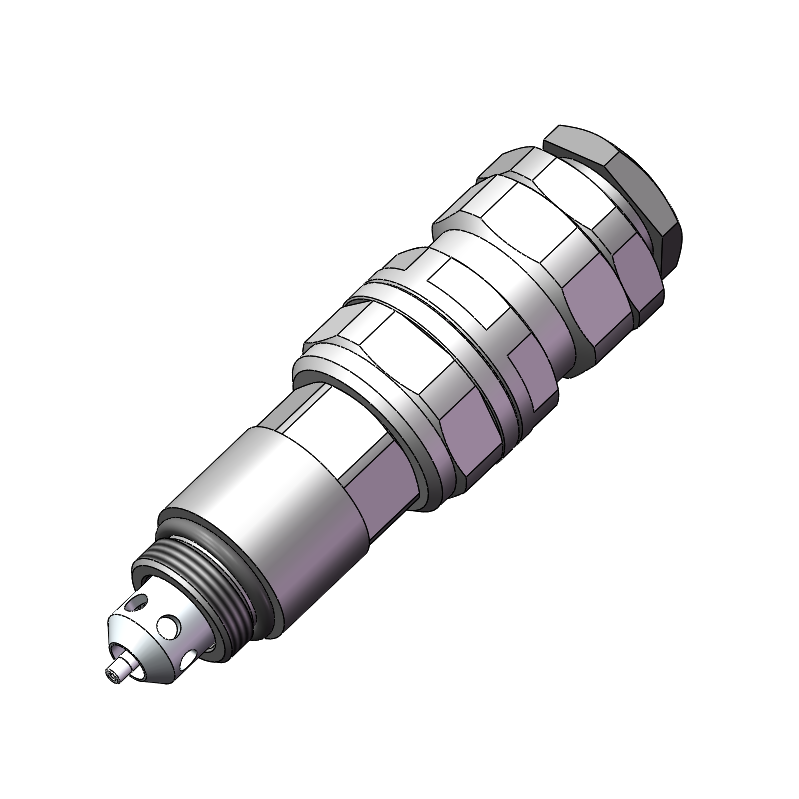

DN6 Direct Acting With Anti-Cavitation Poppet Type Cartridge Relief Valve,Used as a pressure limiting device to protect hydraulic circuits.

DN6 Direct Acting With Anti-Cavitation Poppet Type Cartridge Relief Valve

JRD06-01

Product Introduction:

The Direct Acting With Anti-Cavitation Cartridge Relief Valve is a common overload protection and anti-cavitation component in hydraulic systems. Its core feature is that the valve core is directly driven by hydraulic pressure (without pilot control). It has a simple structure and fast response. Direct Acting With Anti-Cavitation Cartridge Relief Valve is often used in closed hydraulic systems with medium and low pressures or those with high requirements for dynamic performance.

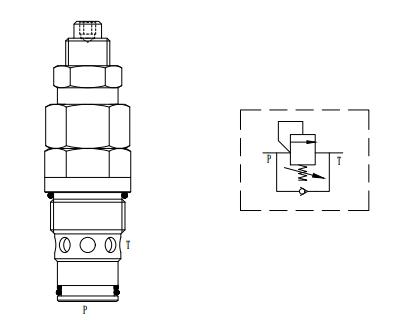

OPERATION:

Overload pressure relief:

When the system pressure exceeds the spring setting value, the hydraulic pressure pushes the valve core to compress the spring, and the high-pressure oil flows back to the oil tank (or low-pressure side) through the pressure relief channel to achieve rapid pressure relief.

Oil replenishment process:

When the pressure on the low-pressure side of the system drops due to leakage or cavitation, the pressure difference between the oil replenishment chamber and the low-pressure side drives the valve core to move in the opposite direction, and the oil from the oil tank or the oil replenishment pump enters the low-pressure side to Anti-Cavitation.

FEATURES:

Fast response speed: The direct-acting structure has no pilot control link. The valve core acts directly when the pressure fluctuates, and the dynamic characteristics are good.

The valve core and valve sleeve are hard to handle and durable.

Fast response to pressure change.

Industrial conventional valve hole.

SPECIFICATIONS:

Max.Working Pressure:260bar(3770psi)

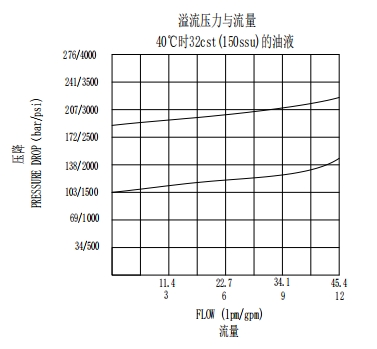

Flow:See performance curve.

Internal leakage:Under the opening pressure of 75%, the leakage is ≤10mL/min.

Opening Pressure Definition:Pressure measurement when the flow reaches 2.5% of the nominal flow.

Clossing Pressure:90% of opening pressure

Reverse Opening Pressure: ≤1.5bar(22psi)

Filtering Accuracy: 25 μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

Standard Pressure Range: 30 ~ 140 bar (435 ~ 2030 psi)

160 ~ 260 bar (2320 ~ 3770 psi)

CHARACTERISTIC:

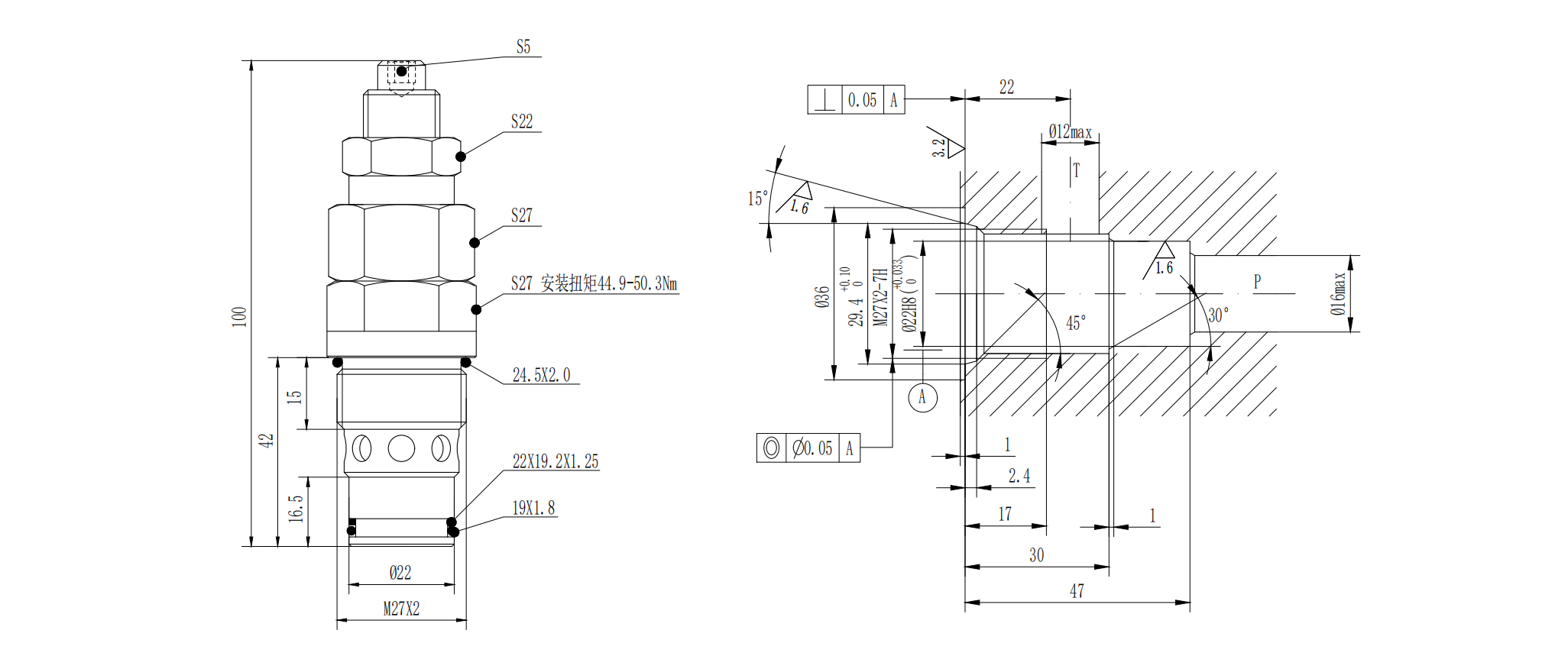

DIMENSIONS:

Typical application scenarios:

Closed hydraulic circuit (such as hydraulic motor drive system):

In equipment such as winches and travel motors, quick oil replenishment prevents air suction and Anti-Cavitation, while also relieving pressure to protect the motor.

Small construction machinery (such as small excavators, forklifts):

Used for overload protection of boom hydraulic cylinders, adapting to frequent start and stop and sudden load changes.

Servo system auxiliary circuit:

Provide fast pressure buffering for precision hydraulic systems to reduce the impact of pressure shock on servo valves.