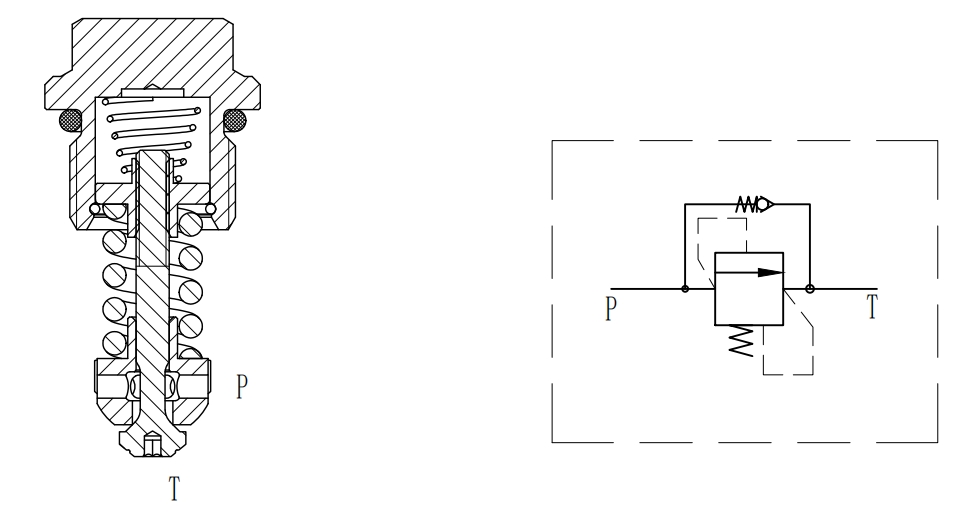

The Direct Acting With Anti Cavitation Relief Valve combines in one compact insert cartridge the typical function of shock relief valve and anticavitation through the check valve.

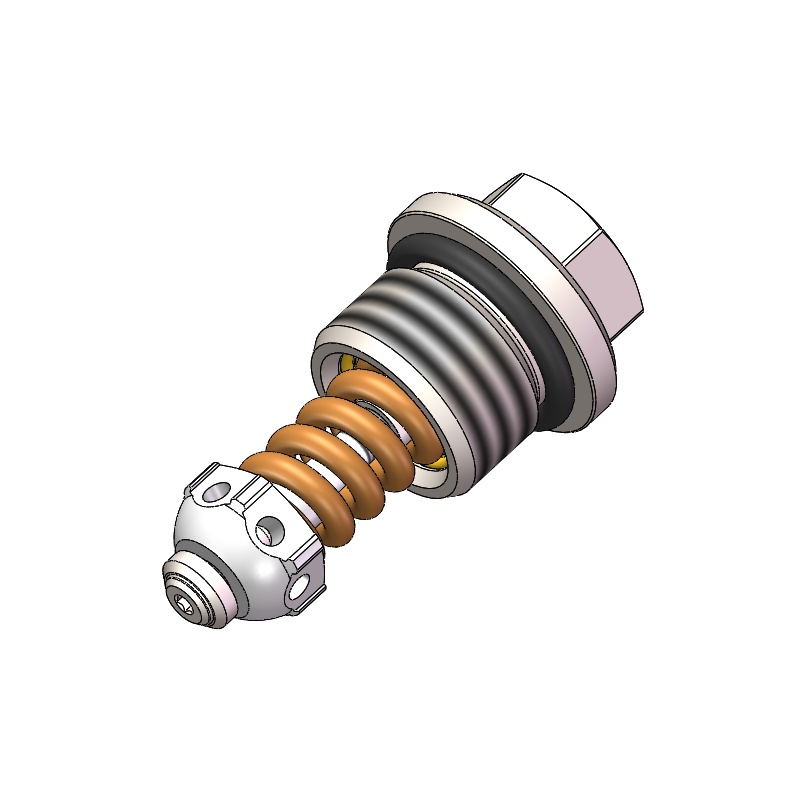

DN6 Direct Acting With Anti Cavitation Poppet Type Relief Valve

JRD06-14

OPERATION OF Direct Acting With Anti Cavitation Relief Valve:

Positive overflow: When the system pressure exceeds the spring setting value, the valve core is pushed open by the oil, and the excess oil returns to the oil tank through the overflow port to maintain the system pressure stable (the same as the traditional direct-acting overflow valve).

Reverse oil replenishment: When the system needs oil replenishment (such as load locking or insufficient oil pressure), the reverse oil pressure acts on the other side of the valve core, pushing the valve core to open the oil replenishment channel, and the external oil is replenished to the system through the valve body to prevent cavitation or pressure drop.

FEATURES OF Direct Acting With Anti Cavitation Relief Valve:

The regulator ensures that the spring will not be compacted.

Optional optional pressure range up to 299bar(4336psi).

The valve core and valve sleeve are hard to handle and durable.

Fast response to pressure change.

Industrial conventional valve hole.

Bidirectional function integration

The traditional direct-acting relief valve only supports one-way overflow, while the oil replenishment type realizes forward and reverse oil circuit switching through structural optimization (such as dual valve cores or composite oil circuits) to meet the needs of complex working conditions.

High response and stability

The direct-acting design allows the valve core action to be directly controlled by oil pressure and spring force, with fast response speed, which is suitable for dynamic pressure regulation scenarios.

Anti-pollution ability

The use of carbide valve cores or special sealing designs can reduce the problem of sticking caused by oil contamination and improve reliability.

Oil replenishment flow control

The oil replenishment channel is usually equipped with a throttle hole or adjustable damping to avoid system pressure fluctuations caused by excessive oil replenishment.

SPECIFICATIONS:

Max.Working Pressure:400bar(5800psi)

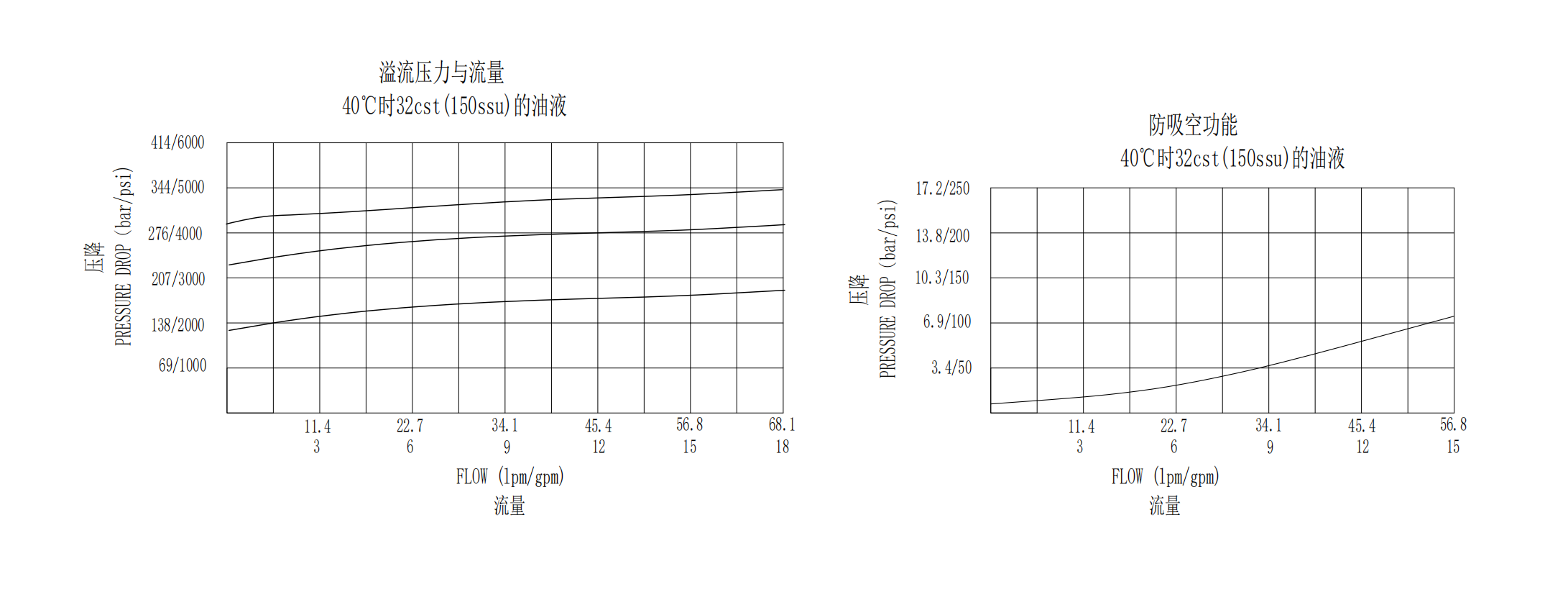

Flow:See performance curve.

Internal leakage:Under the opening pressure of 75%, the leakage is ≤10mL/min.

Opening Pressure Definition:Pressure measurement when the flow reaches 2.5% of the nominal flow.

Clossing Pressure:90% of opening pressure

Filtering Accuracy: 25 μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

Standard Pressure Range: 101 ~ 175 bar (1465 ~ 2538 psi)

250 ~ 320 bar (3625 ~ 4640 psi)

320 ~ 400 bar (4640 ~ 5800 psi)

CHARACTERISTIC:

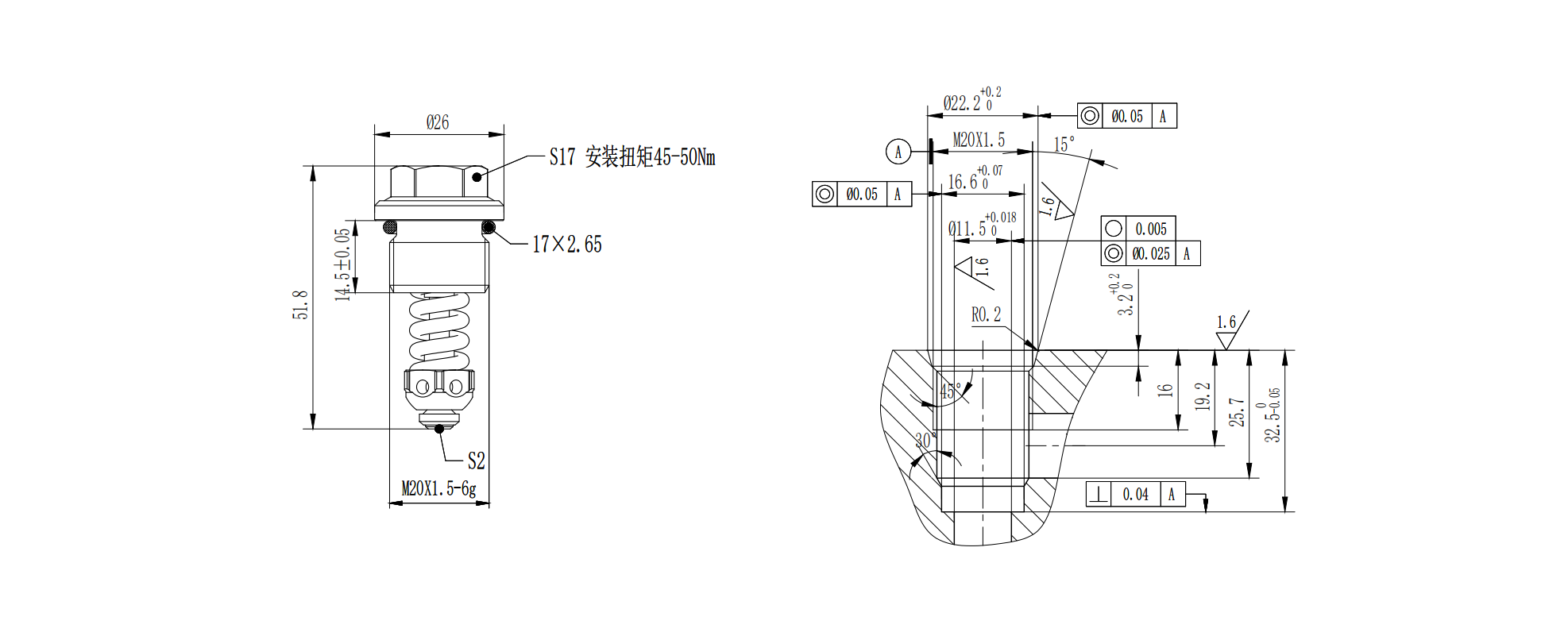

DIMENSIONS: