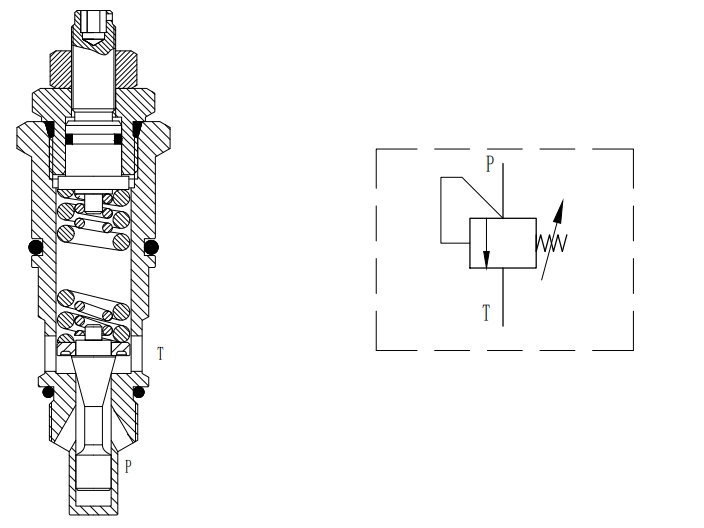

Directly Relief Valve is relieving thepressure by a poppet on its sealing seat. The poppet is pushed toopen and reliving the flow through T port when the pressure on Pport is higher than the spring pressing force. The spring force isavailable to adjust by regulating the head hexagon of the Directly Relief Valve with easy and flexible operation

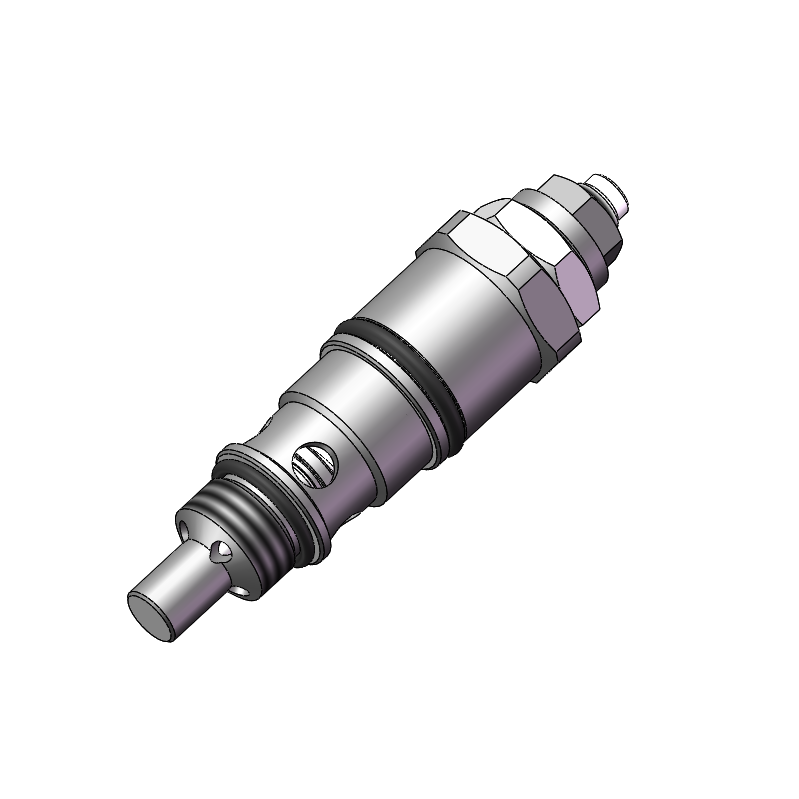

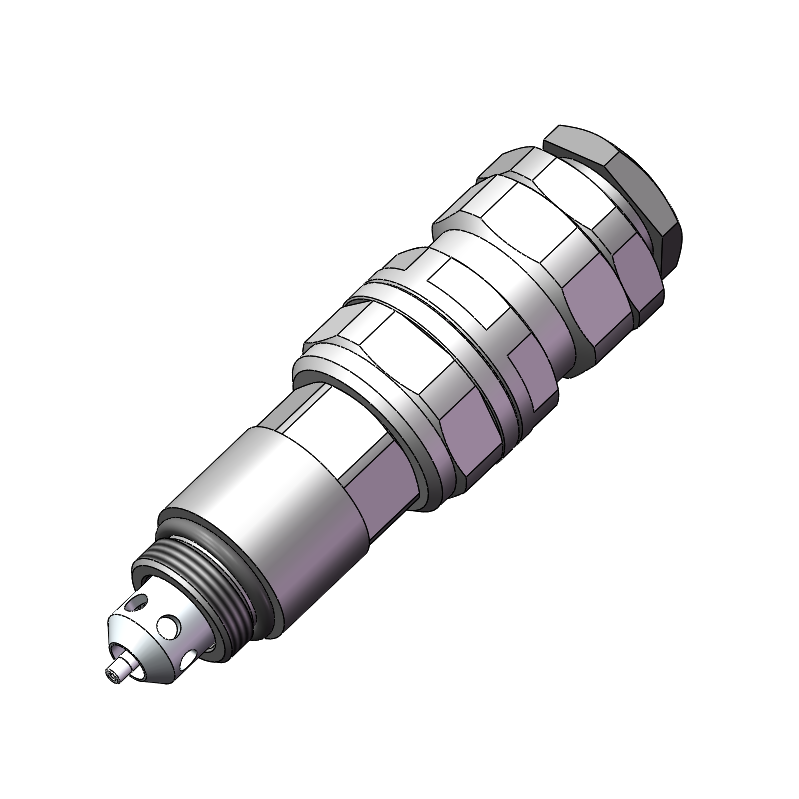

DN8 Direct Acting Poppet Type Cartridge Relief Valve

JRD08-11

PRODUCT INTRODUCTION:

Directly Relief Valve is relieving thepressure by a poppet on its sealing seat. The poppet is pushed toopen and reliving the flow through T port when the pressure on Pport is higher than the spring pressing force. The spring force isavailable to adjust by regulating the head hexagon of the Directly Relief Valve with easy and flexible operation

OPERATION:

A screw-in, cartridge style, directly operated, poppet type, normally closed hydraulic relief valve. It’s typically used to protect hydraulic components from pressure transients. When the pressure at the Inlet (P) reaches the valve setting, the valve starts to open to tank (T) throttling flow to minimize the pressure rise. The innovative geometry of the deflector provides in fact a very low rise rate, and the poppet design guarantees great stability. The cartridge offers quick response to load changes in hydraulic circuits requiring low internal leakage as well as limited hysteresis.

FEATURES:

Easily pressure adjustment and threadsinstallation

Factory pre-setting pressure available for quickreplacement

The valve core and valve sleeve are hard to handle and durable.

Fast response to pressure change.

JRD08-11DIRECTLY OPERATED RELIEF VALVE SPECIFICATIONS:

Max.Working Pressure:240bar(3480psi)

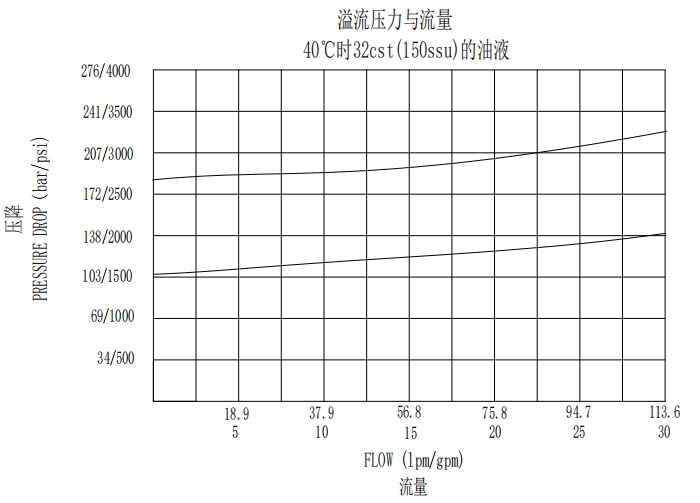

Flow:See performance curve.

Internal leakage:Under the opening pressure of 75%, the leakage is ≤10mL/min.

Opening Pressure Definition:Pressure measurement when the flow reaches 2.5% of the nominal flow.

Clossing Pressure:90% of opening pressure

Filtering Accuracy: 25 μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

Standard Pressure Range: 55 ~ 140 bar (798 ~ 2030 psi)

160 ~ 240 bar (2320 ~ 3480 psi)

DIRECTLY RELIEF VALVE CHARACTERISTIC:

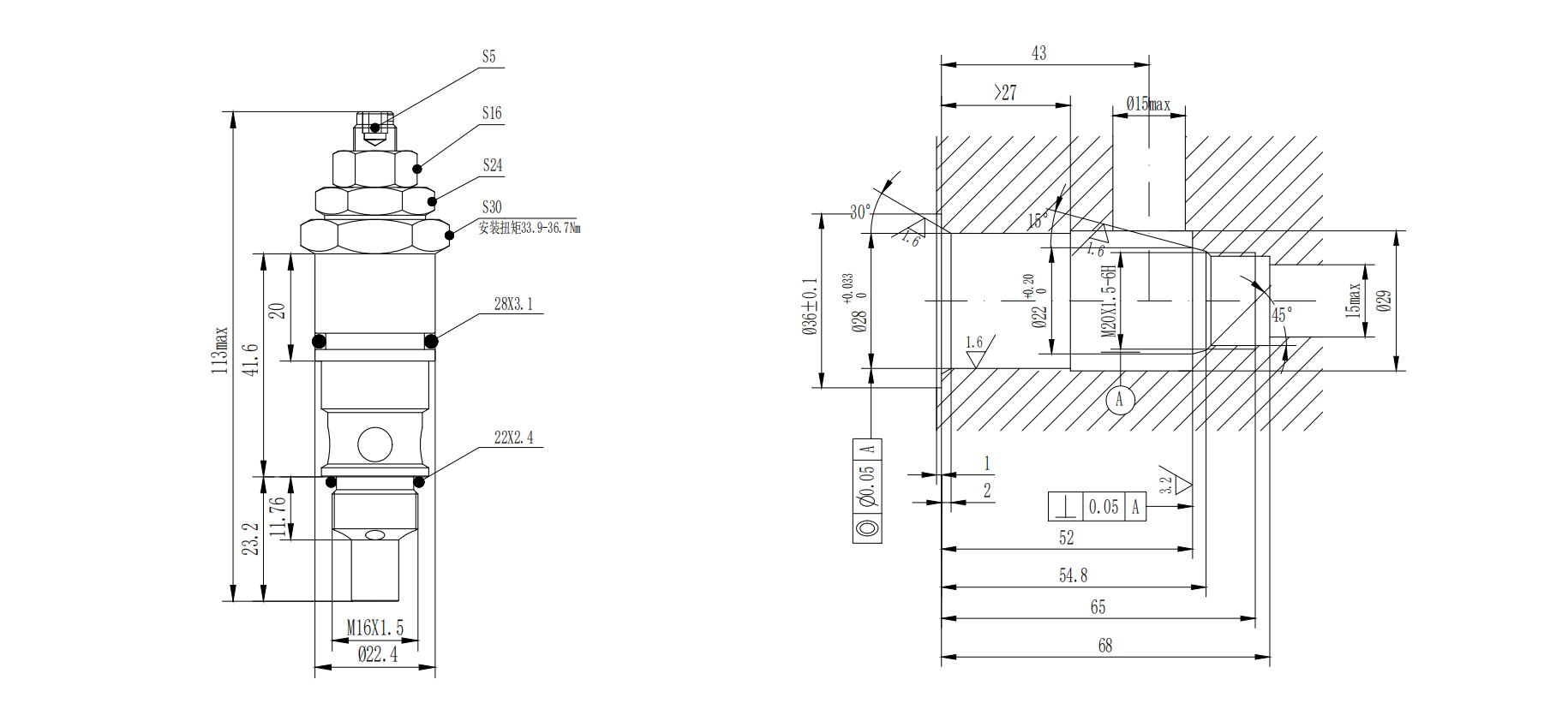

DIRECTLY RELIEF VALVE DIMENSIONS:

Application Scenario Of Directly Operated Relief Valve:

Engineering machinery: In the hydraulic systems of engineering machinery such as loaders and excavators, directly operated Relief Valve can be used as safety valves to protect the hydraulic system from damage caused by excessive pressure and ensure the safe operation of engineering machinery.

Injection molding machine: In the hydraulic system of the injection molding machine, directly operated Relief Valve can be used to adjust and stabilize the injection pressure, holding pressure, etc. to ensure the quality of injection molded products.

Marine hydraulic system: Directly operated Relief Valve can be used in hydraulic equipment such as ship steering gear and cargo cranes to control the pressure of the hydraulic system and ensure the normal operation and safety of ship equipment.

FAQ:

What is a directly operated Relief Valve?

The Directly Relief Valve is like a "pressure relief switch" controlled by hydraulic pressure and spring. When the force of the oil pressure pushing the valve core is greater than the force of the spring pressing the valve core, the valve opens to release oil and reduce pressure; when the oil pressure drops, the spring pushes the valve back to reduce or close it. Through this automatic on-off adjustment, the maximum pressure of the system is limited to the value set by the spring. The core is the direct competition and dynamic balance between the hydraulic pressure and the spring force.

directly operated