The Direct Acting Spool Type Cartridge Relief Valve is a pressure control valve that combines the characteristics of a direct-acting relief valve with an LS (Load Sensing) port. The direct-acting relief valve uses the principle of balancing the liquid pressure on the valve core with the spring force to control the opening and closing of the valve, thereby adjusting the system pressure; the LS port is used to introduce a load pressure signal, so that the relief valve can more accurately control the system pressure according to the load changes.

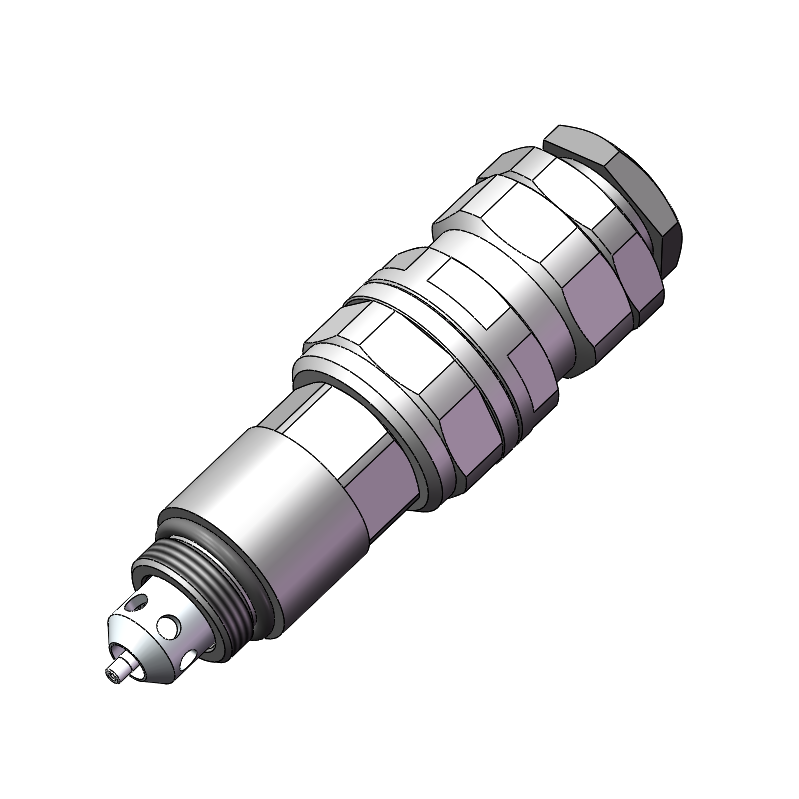

DN8 Direct Acting Spool Type Cartridge Relief Valve

JRD08-18

PRODUCT INTRODUCTION:

The Direct Acting Spool Type Cartridge Relief Valve is a pressure control valve that combines the characteristics of a direct-acting relief valve with an LS (Load Sensing) port. The direct-acting relief valve uses the principle of balancing the liquid pressure on the valve core with the spring force to control the opening and closing of the valve, thereby adjusting the system pressure; the LS port is used to introduce a load pressure signal, so that the relief valve can more accurately control the system pressure according to the load changes.

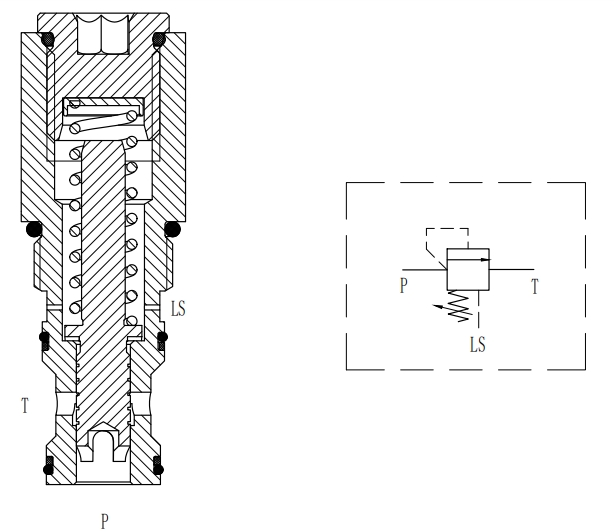

OPERATION:

When the system pressure is lower than the set pressure of the Cartridge Relief Valve, the valve core is in a closed state under the action of the spring force, the oil cannot overflow through the relief valve, and the system pressure increases with the increase of load. When the system pressure reaches the set pressure of the Direct Acting Spool Type Cartridge Relief Valve, the valve core opens, and the oil flows back to the tank through the relief valve, so that the system pressure remains near the set value. The sensor connected to the LS port will sense the change in load pressure and feed back the signal to the control part of the relief valve, thereby adjusting the preload force of the spring or the position of the valve core, so that the opening pressure of the relief valve can be dynamically adjusted according to the change in load pressure.

FEATURES:

The valve core and valve sleeve are hard to handle and durable.

Fast response speed: Able to adjust system pressure in time to adapt to rapid changes in load.

Industrial conventional valve hole.

Precise pressure control: The system pressure can be accurately adjusted according to the actual load conditions, which improves the control accuracy of the system.

Good energy-saving effect: It reduces energy loss and reduces the energy consumption of the system.

SPECIFICATIONS:

Max.Working Pressure:315bar(4568psi)

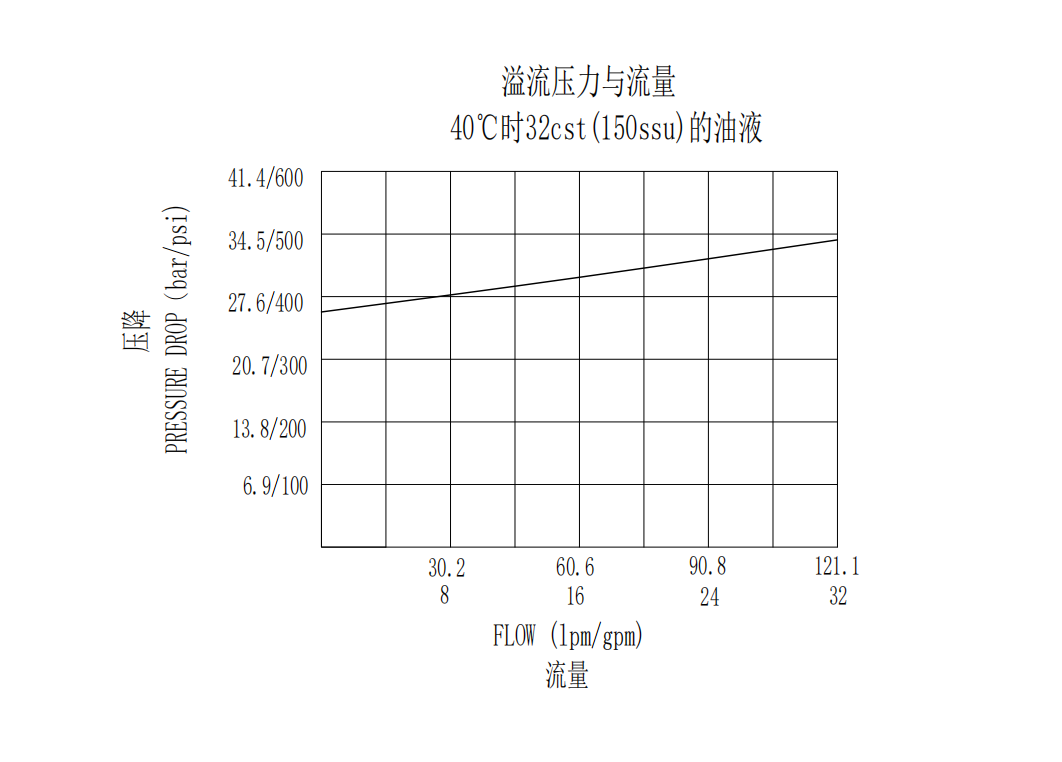

Flow:See performance curve.

Internal leakage:Under the opening pressure of 75%, the leakage is ≤100mL/min.

Opening Pressure Definition:Pressure measurement when the flow reaches 2.5% of the nominal flow.

Clossing Pressure:90% of opening pressure

Filtering Accuracy: 25 μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

Standard Pressure Range: 20 ~ 35 bar (290 ~ 508 psi)

CHARACTERISTIC:

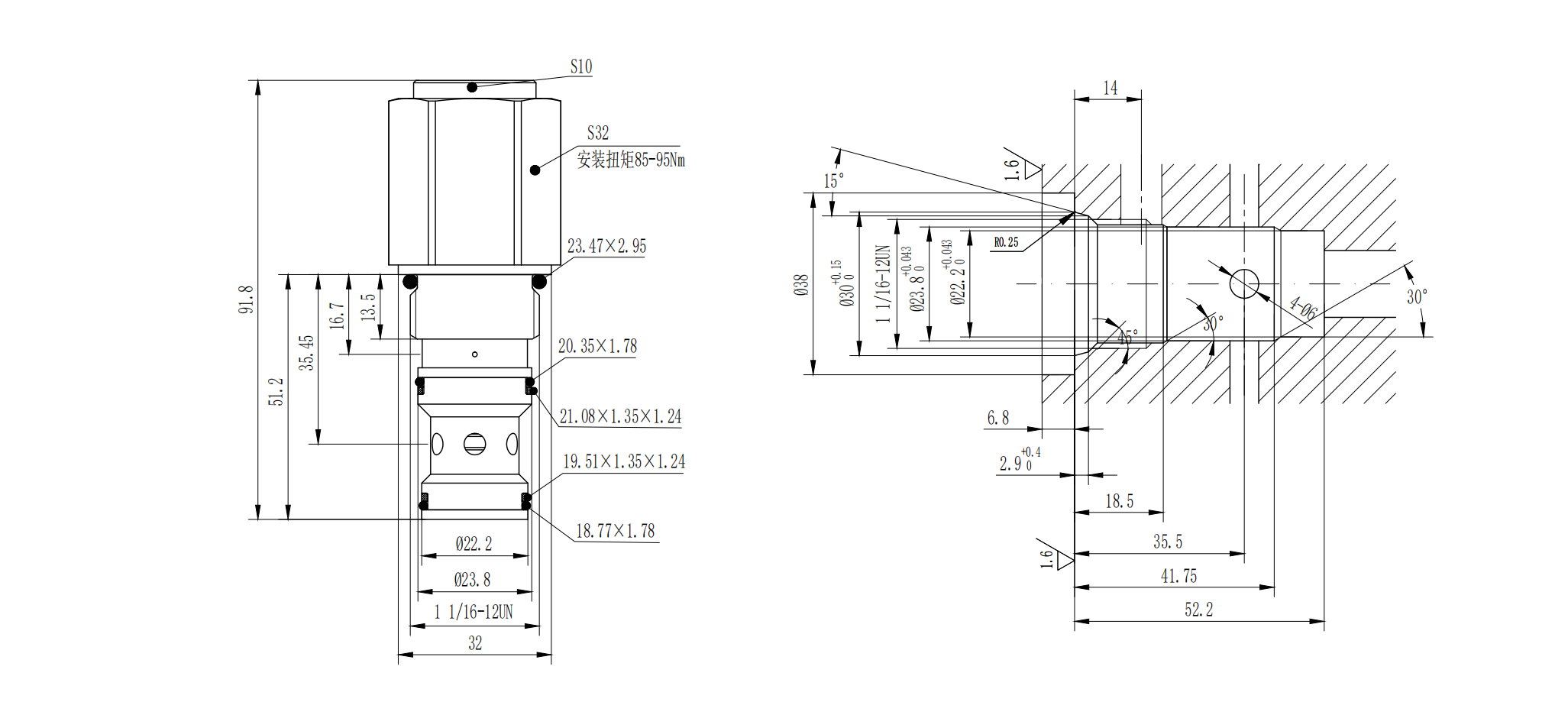

DIMENSIONS:

Application Scenario:

Engineering machinery: such as excavators, loaders, etc.

Metallurgical equipment: such as rolling mills, continuous casting machines, etc.

Ship hydraulic systems: various hydraulic equipment on ships, such as steering gears, cranes, etc.