Pilot Operated Check Safety Valve are used as pressure limiting devices in hydraulic circuits requiring fast response and low hysteresis.

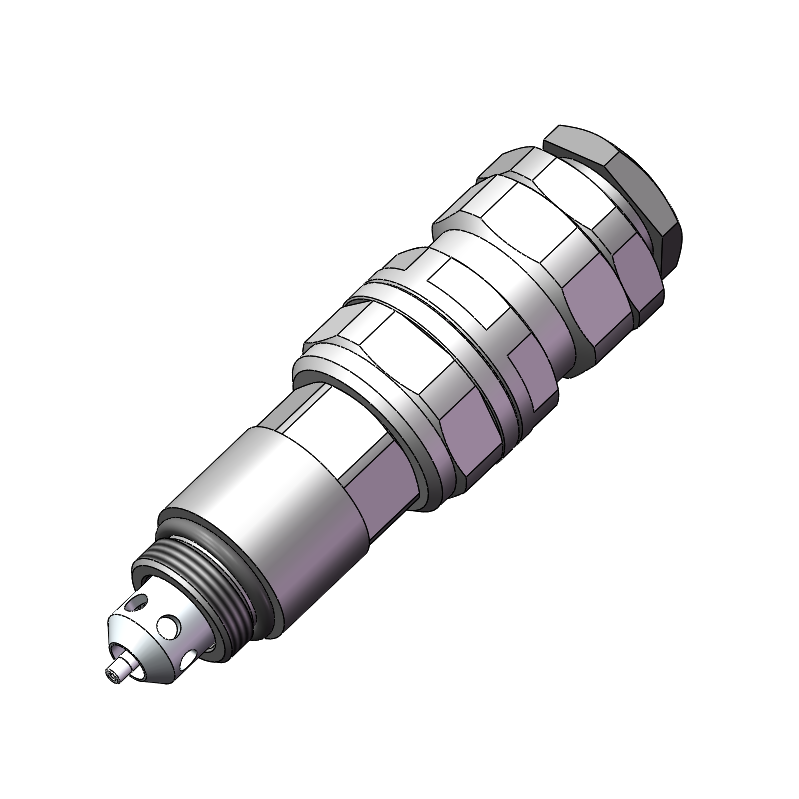

DN8 Pilot Operated Poppet Type Check Cartridge Relief Valve

JRPC08-02

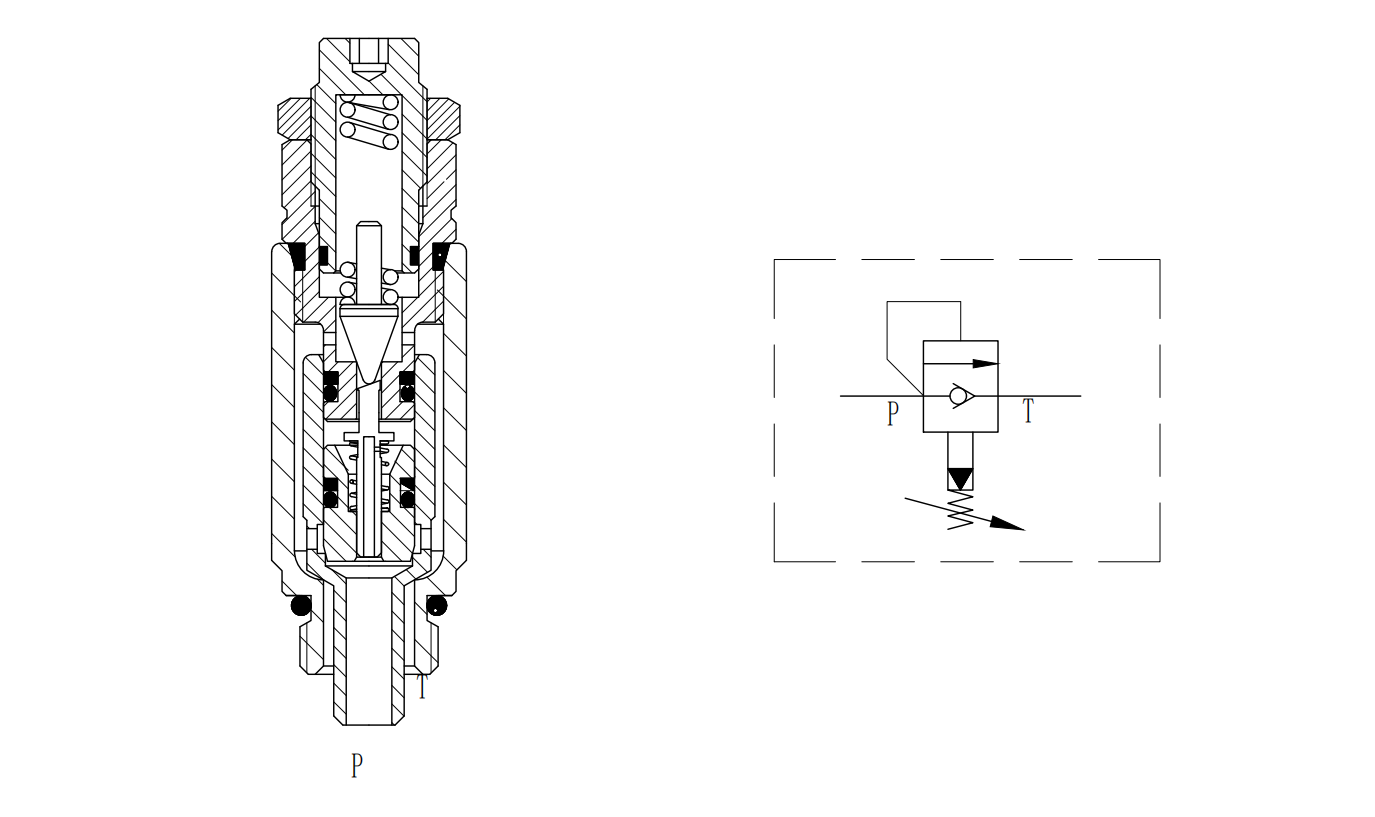

OPERATION:

1. Two-stage pressure control mechanism

Pilot stage: The Pilot Operated Check Safety Valve adopts a small-size cone valve structure, and sets the system main pressure value through an independent pressure regulating spring. When the system pressure reaches the pilot valve opening pressure of the Pilot Operated Check Safety Valve, a small amount of oil overflows through the pilot valve port, forming a pressure difference between the upper and lower chambers of the main valve core (using the main valve damping hole to generate pressure drop).

Main stage: The main valve core of the Cartridge Valve overcomes the main spring force under the action of the pressure difference to open and achieve large flow overflow. Compared with the direct-acting relief valve, the Pilot Operated Check Safety Valve replaces the main stage large spring with a small pilot stage spring, which significantly reduces the manual pressure adjustment operation force and has higher pressure control accuracy.

2. Response characteristic optimization

Dynamic overshoot suppression: The Cartridge Valve can control the pressure overshoot within 10% of the set pressure by optimizing the size of the main valve core damping hole, the pilot valve spring stiffness and the main valve cavity volume. It is suitable for precision hydraulic systems that are sensitive to pressure shocks.

Difference in opening and closing characteristics: The difference between the opening pressure and the closing pressure of the Cartridge Valve (pressure hysteresis) is usually ≤5% of the set pressure, which is better than the direct-acting relief valve (hysteresis can reach 10%~15%), which is reflected in a smoother pressure switching process.

FEATURES:

Precise pressure control: The pilot structure can finely adjust and stably control the system pressure, with small pressure regulation deviation, which can meet the requirements of systems with high pressure accuracy.

Fast response speed: The pilot valve is sensitive to pressure changes, which can enable the main valve to respond quickly and adjust the system pressure in time to ensure stable operation of the system.

Space saving: The threaded plug-in design is compact and only takes up the space of one threaded hole on the manifold during installation, which is suitable for hydraulic systems with limited space.

Reliable oil replenishment: The oil replenishment function can effectively prevent the pressure drop caused by leakage, impact, etc. in the system, ensure the stability of system pressure, and improve system reliability.

SPECIFICATIONS OF Cartridge Valve:

Max.Working Pressure:315bar(4568psi)

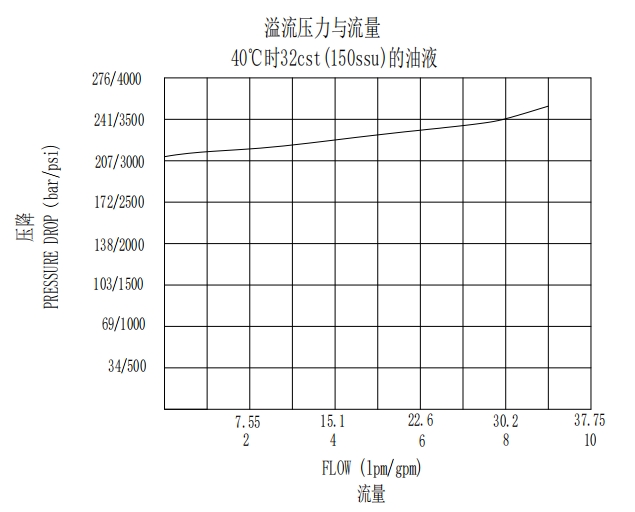

Flow:See performance curve.

Internal leakage:Under the opening pressure of 75%, the leakage is ≤3mL/min.

Opening Pressure Definition:Pressure measurement when the flow reaches 2.5% of the nominal flow.

Clossing Pressure:90% of opening pressure

Reverse Opening Pressure: ≤2bar(29psi)

Filtering Accuracy: 25 μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

Standard Pressure Range: 160 ~ 315 bar (2320 ~ 4568 psi)

CHARACTERISTIC OF Cartridge Valve:

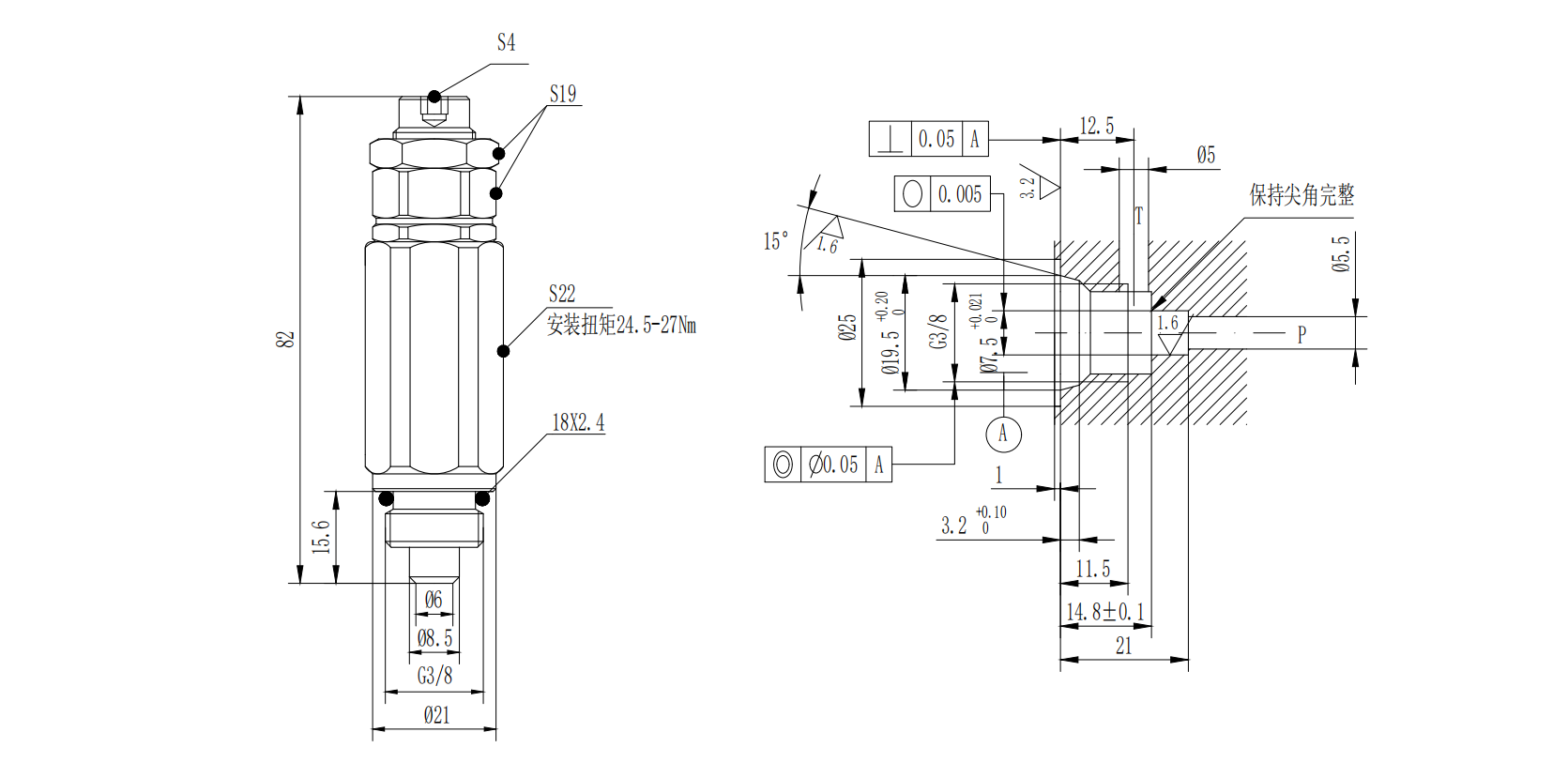

DIMENSIONS OF Cartridge Valve:

Cartridge Valve Cartridge Valve