P120 Series Monoblock Valve with middle-high pressure monoblock directional valve is developed based on Europe technology.

P120 Series Monoblock Directional Valve

MODEL:P120 Monoblock Directional Valve

APPLICATIONS & FEATURES:

P120 Series Monoblock Valve with middle-high pressure monoblock directional valve is developed based on Europe technology.

Inner check valve:The check valve inside the valve body is to insure the hydraulic oil will not be returned.

Inner relief valve: The relief valve inside the valve body is able to adjust the hydraulic system working pressure.

Oil circuit form: Parallel oil circuit, ensure that the oil inlet pressure of each reversing valve is equal, and the return oil goes directly to the main return oil port

Control Way: Manual control, pneumatic control, electric and pneumatic control,hydraulic and electriccontrol and etc.

Valve construction:monoblock construction, 1-7 levers.

Spool Function: A,O,Y.

Option: Hydraulic lock is available to be added A and B port.

P120 Series Monoblock Valve are widely used in the hydraulic systems of forklifts, sanitation vehicles, and small loaders.

Integrated design: integrated reversing valve, overflow valve and other functional modules, reducing external connections and improving system reliability.

High-pressure bearing: suitable for high-pressure systems (up to 315bar), strong durability, suitable for heavy-load conditions.

High efficiency and energy saving: optimized flow channel design, reduced energy consumption, fast response speed.

SPECIFICATIONS:

Nom.Pressure(MPa) | Max.pressure(MPa) | Nom.Flow rate(L/min) | Max.Flow rate(L/min) | Back pressure(MPa) | Hydraulic oil | ||

Tem.rang (℃) | Visc.rang(mm²/S) | Filtrating accuracy(μm) | |||||

| 20 | 31.5 | 120 | 160 | ≤1 | -20~+80 | 10~400 | ≤10 |

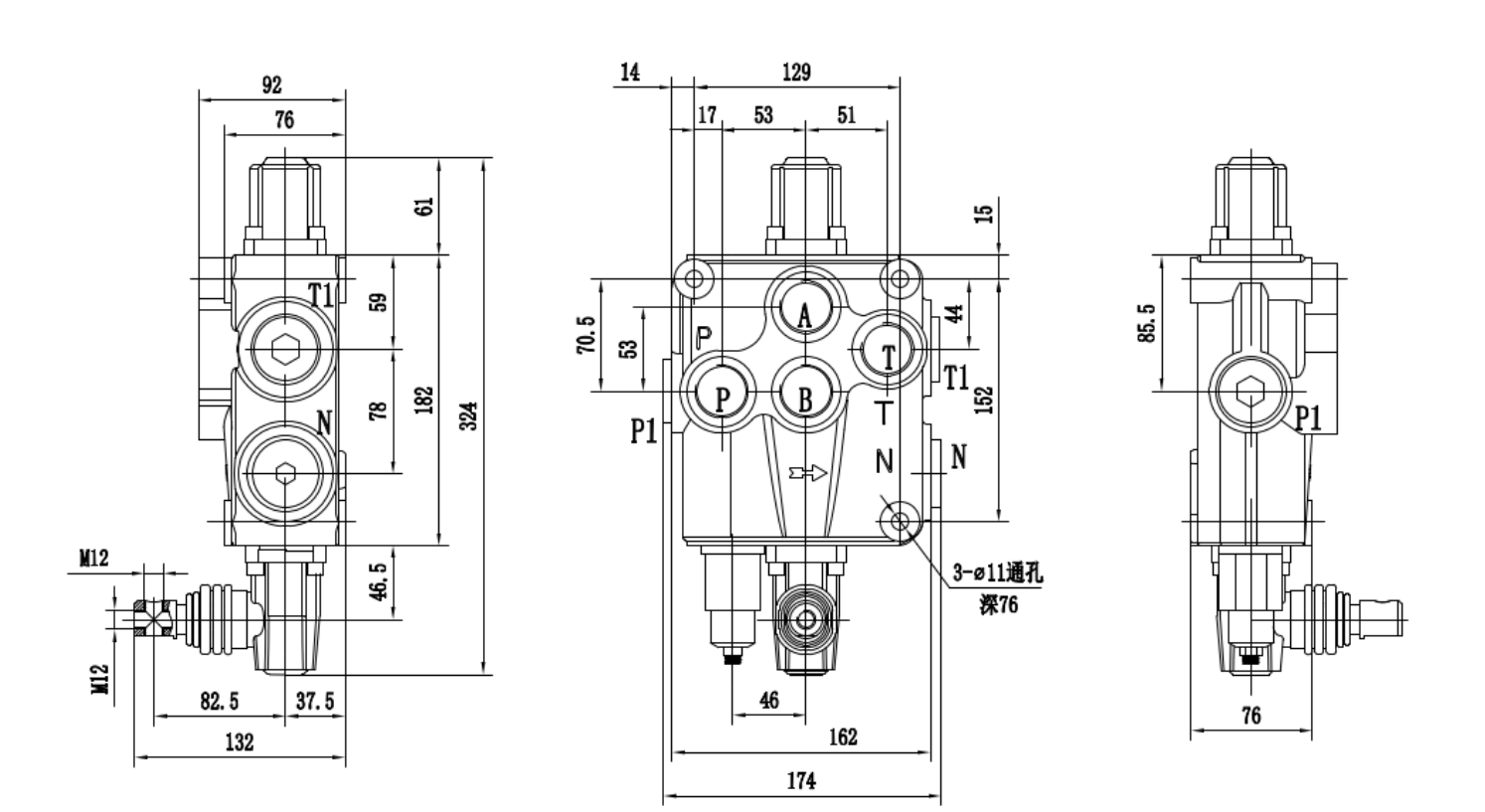

P120 SERIES MONOBLOCK VALVE DIMENSIONS DATA:

Typical Application Areas:

Engineering machinery: Control the movements of excavator buckets, booms, etc., and adjust the flow and pressure of hydraulic systems.

Agricultural machinery: Hydraulic drive systems for tractors and harvesters to achieve stable power output.

Industrial equipment: Control corrosive media or high-viscosity fluids in chemical, shipbuilding and other fields

Structure of P120 Series Monoblock Valve:

Integral structure: multiple reversing valves, safety valves and various additional valves are integrated into one valve body, which has a compact structure, reduces pipeline connections, reduces the risk of leakage, and is also easy to install and maintain.

Valve core form: It adopts a sliding valve structure with multiple sliding valve functions such as A, O, and Y, which can be combined arbitrarily according to actual needs to achieve different hydraulic control functions.

Oil circuit connection: It adopts a parallel oil circuit design. Each reversing valve is independent of each other and can work at the same time. It can control different actuators, such as hydraulic cylinders, hydraulic motors, etc., so that multiple working mechanisms can act simultaneously or separately, improving work efficiency and flexibility.

Scalability: The number of valves that can be made is generally 1-7. Users can choose the appropriate number of links according to actual needs to meet different hydraulic system control requirements.