Check Poppet Reverse Valve designed for use as a blocking or load-holding device.

DN10 Poppet Reverse Check Valve

JCX10-02

Product Introduction:

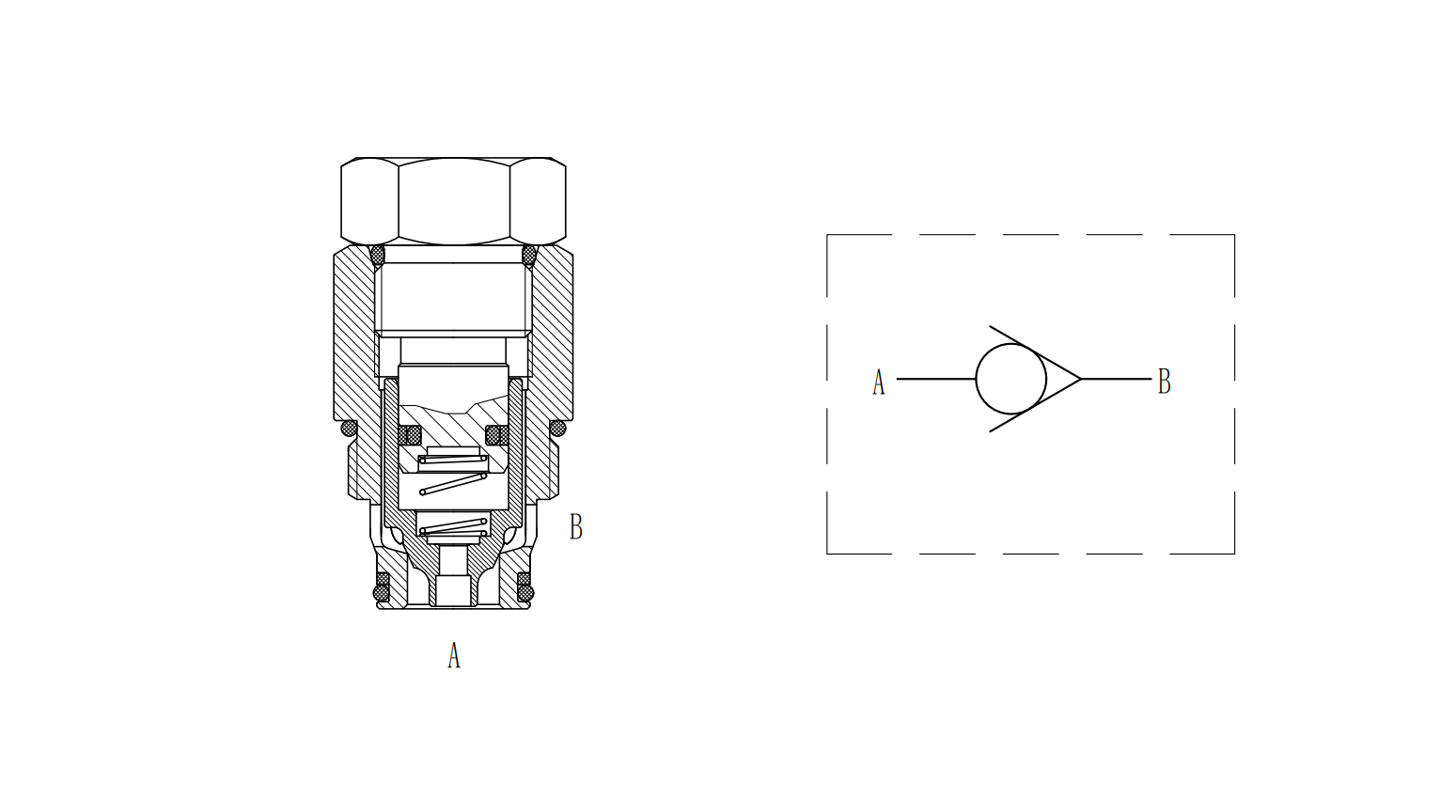

Poppet Reverse Check Valves are a special type of check valve where the free flow path is from the side of the cartridge valve to the nose. They functionally are the same as the standard check valve. Poppet Reverse Check Valves are occasionally used by manifold designers to simply the flow path design of their blocks.

OPERATION OF Poppet Reverse Check Valve:

When this valve is used, it allows the liquid flow from port B to port A with very low pressure drop, and prevents the liquid flow from port A to port B at the same time.

FEATURES:

Hardened, precision ground parts for durability

Poppet type construction for minimal leakage

Fully guided poppet for smooth operation

Good contamination tolerance

Quick response: The direct-acting structure enables the valve core to respond quickly to pressure changes. Once the reverse pressure reaches the opening value, the valve core opens quickly and the reverse fluid can pass immediately.

Compact structure: The threaded plug-in design makes it small in size and suitable for installation in hydraulic or pneumatic systems with limited space, which facilitates system integration and layout optimization.

Good sealing: Reasonable valve core and valve seat design and precision machining ensure reliable sealing during forward cutoff, prevent fluid leakage, and ensure normal operation of the system.

High reliability: The structure is simple and there is no complex pilot control mechanism, which reduces the possibility of failure and improves system reliability.

SPECIFICATIONS:

Max.Working Pressure:315bar(4568psi)

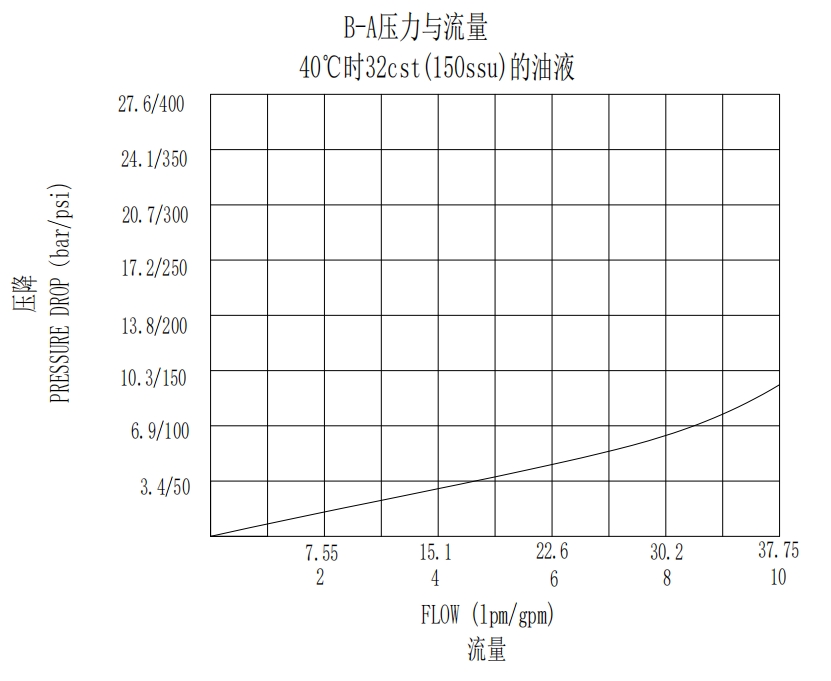

Flow:See performance curve.

Internal leakage:At 200bar(2900psi), the leakage is ≤1mL/min.

Standard opening pressure:1bar(15psi)

Filtering Accuracy: 25 μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

CHARACTERISTIC:

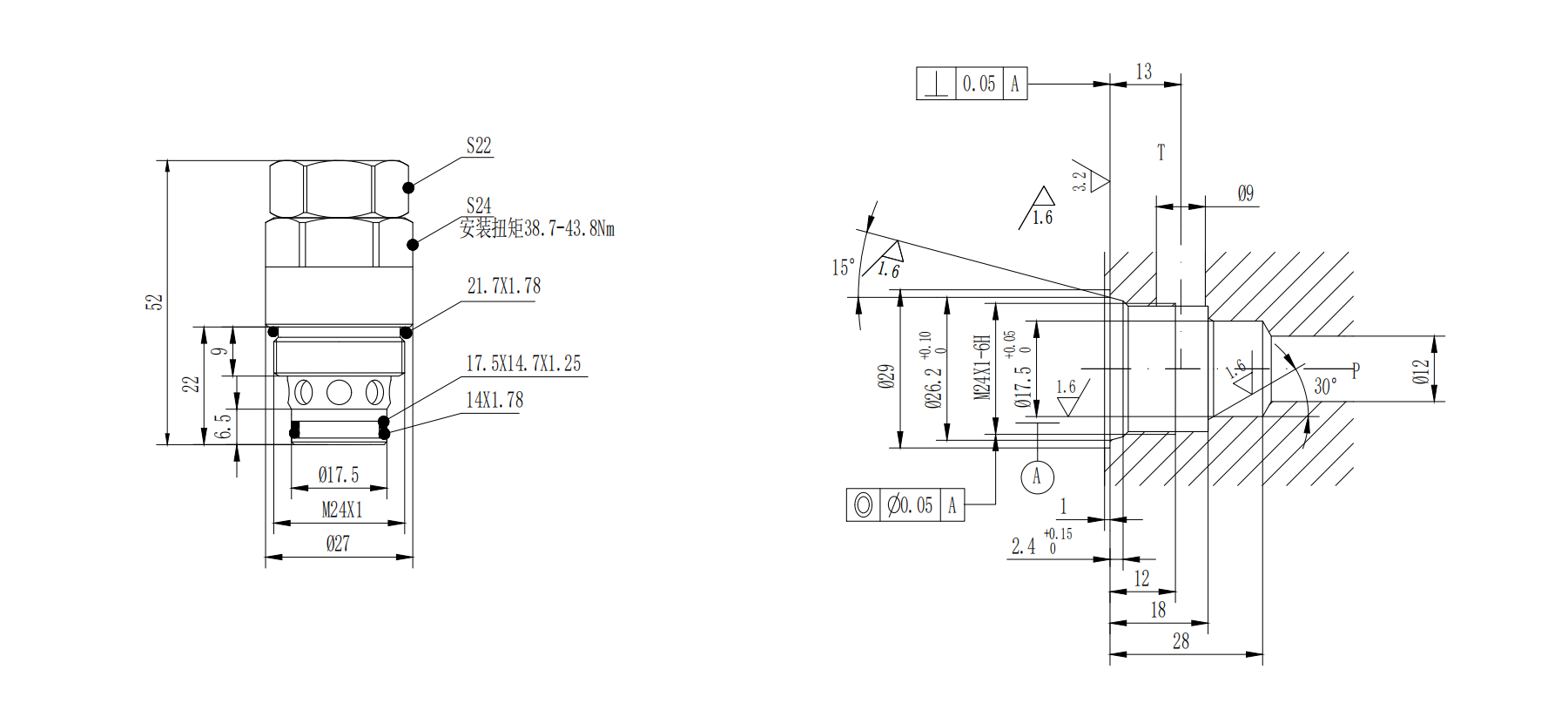

DIMENSIONS:

Application Scenario Of Poppet Reverse Check Valve:

Hydraulic system: Poppet Reverse Check Valve is widely used in the hydraulic systems of various types of engineering machinery (such as excavators, loaders), machine tools, injection molding machines, etc. to control the flow direction of the oil, prevent the oil from flowing back, and protect the safety and normal operation of the system. For example, installing a Poppet Reverse Check Valve on the oil return line of the hydraulic cylinder can prevent the impact and vibration caused by the oil flowing back when the cylinder stops moving.