JSF08-01 family of 2-position, 3-way ball type Shuttle Valve feature a space and cost saving design that fits in an industry common cavity and can operate with hydraulic system flows as high as 50 lpm and pressures up to 420 bar. The simple and effective ball type construction features very fast operation with very low leak performance and is ideal for sequencing, load sensing, or communicating the highest pressure within a specific section of the hydraulic circuit.

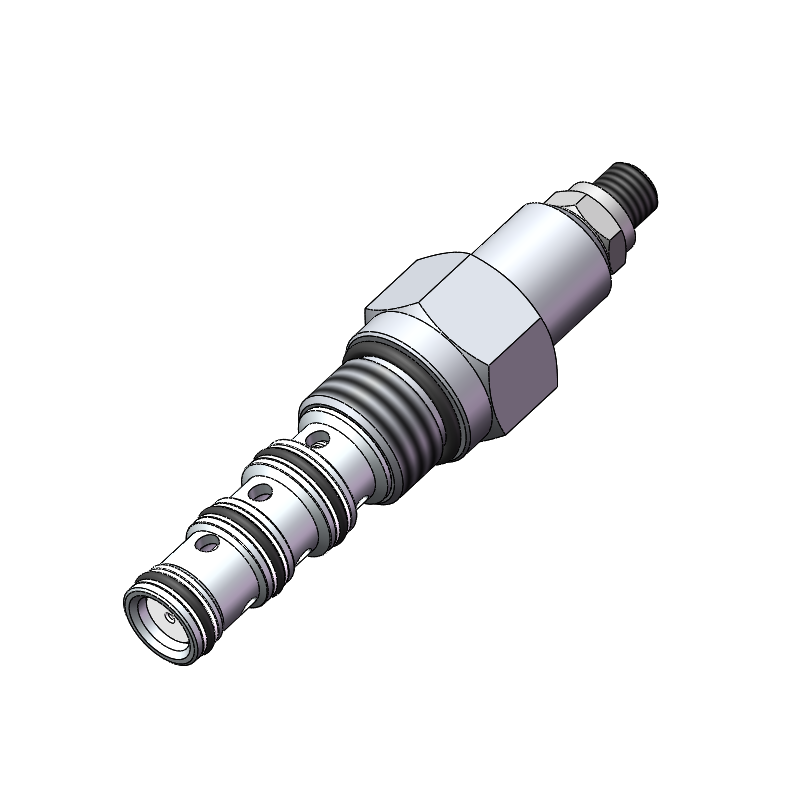

DN8 Ball Type Cartridge Shuttle Valve

JSF08-01

PRODUCT INTRODUCTION:

JSF08-01 family of 2-position, 3-way ball type Shuttle Valve feature a space and cost saving design that fits in an industry common cavity and can operate with hydraulic system flows as high as 50 lpm and pressures up to 420 bar. The simple and effective ball type construction features very fast operation with very low leak performance and is ideal for sequencing, load sensing, or communicating the highest pressure within a specific section of the hydraulic circuit.

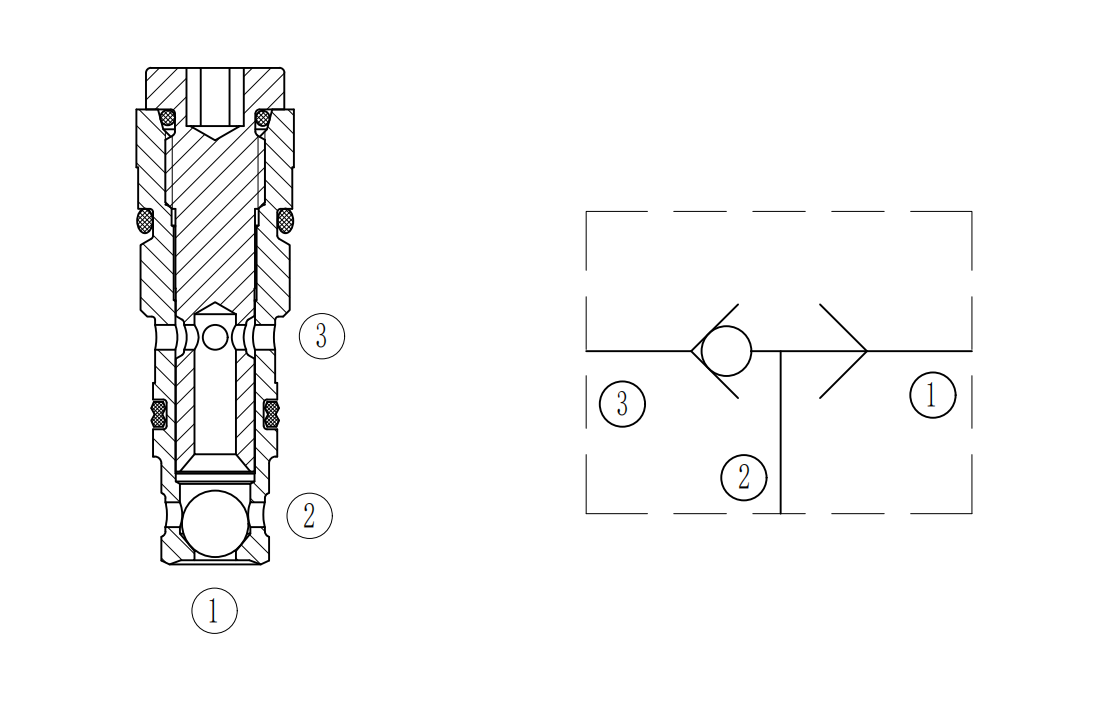

SHUTTLE VALVE OPERATION:

When this valve is used, it is allowed to connect the oil port with higher pressure in the port ① and the port ③ and seal the pressure at the same time.

SHUTTLE VALVE FEATURES:

Sensitive to the change of load direction.

The valve seat is hard-treated, durable and low leakage.

Compact, cost effective design

Industrial conventional valve hole.

Contamination tolerant

SPECIFICATIONS:

Max.Working Pressure:420bar(6090psi)

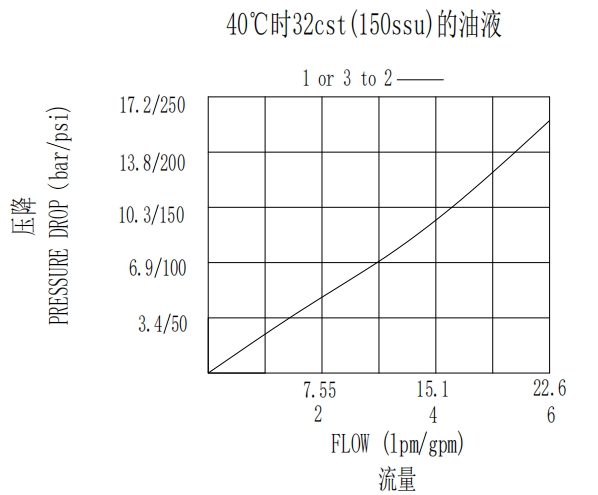

Flow:See performance curve.

Internal leakage:Under the pressure of 400bar(5800psi), the leakage from port ① to port ② and from port ② to port ① is ≤5mL/min.

Filtering Accuracy: 25 μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

CHARACTERISTIC:

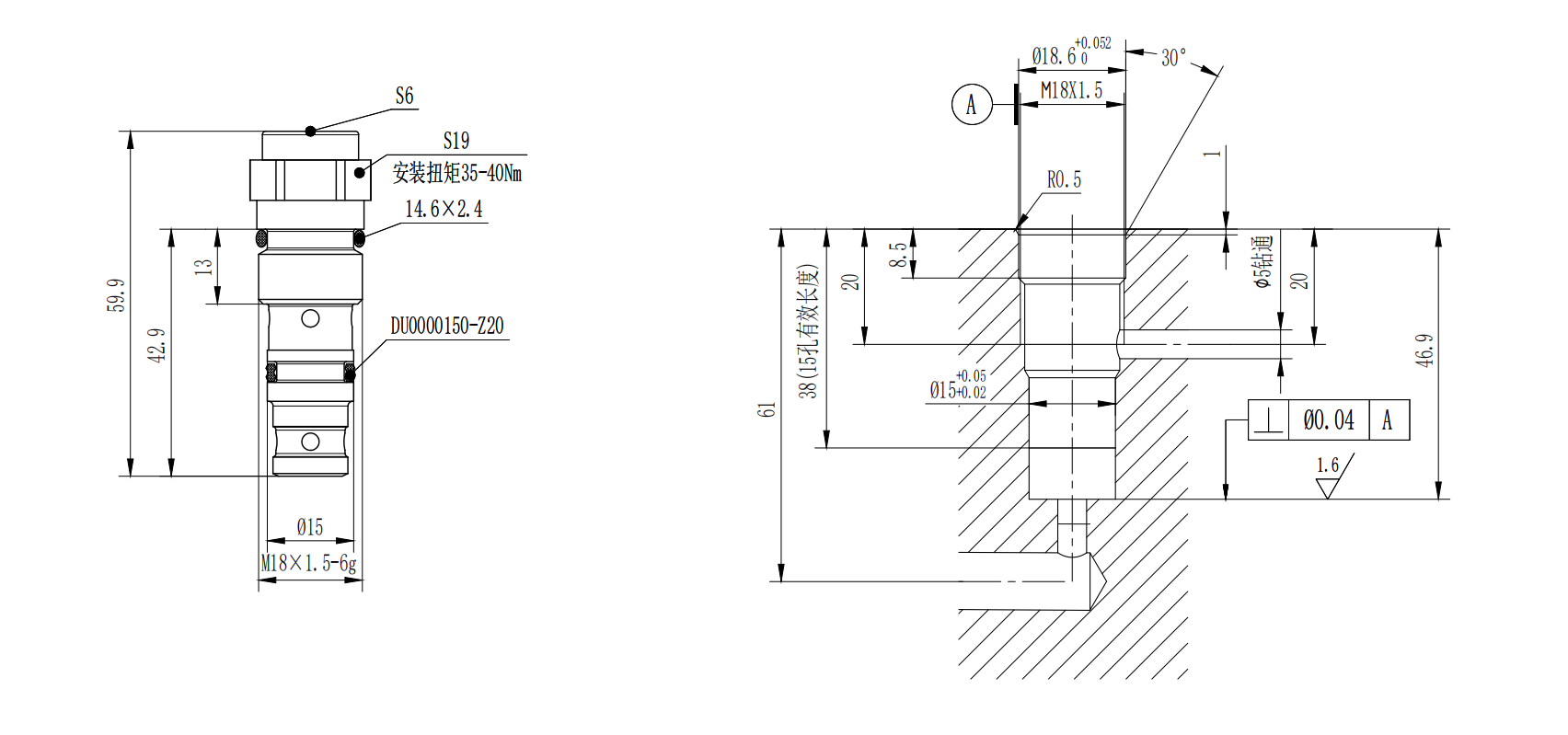

DIMENSIONS:

FAQ:

1.What are the characteristics of the Ball Type Cartridge Shuttle Valve?

Good sealing: Due to the large sealing contact area between the ball shuttle and the valve body, and the seal can provide a good sealing effect, the ball shuttle valve has good sealing performance and can effectively prevent fluid leakage.

Quick reversing: The ball shuttle has a short moving stroke in the valve body, simple operation, and can quickly change the flow direction of the fluid, meeting the needs of some systems with high reversing speed requirements.

Simple structure: Compared with other types of reversing valves, the ball shuttle valve has a relatively simple structure, small size, light weight, and easy installation and maintenance.

Strong wear resistance: The ball shuttle is usually made of wear-resistant materials, which can maintain good performance under the flushing of high-pressure and high-speed fluids and has a long service life.

2.Typical application scenarios

Hydraulic system:

When the system requires dual pumps (main pump + backup pump), the shuttle valve automatically selects the high-pressure oil circuit to ensure stable system pressure.

Prioritize the high-pressure side in the safety circuit to prevent system overload.