Cartridge Check Valve. Main use is as a blocking or load-holding device. The Dual Pilot to Open Check Valve allows flow passage from port B to A: the cartridge has a fully guided check which is spring-biased closed until sufficient pressure is applied at port B to open to A. The flow is blocked in the opposite direction (B to A).

DN10 Direct Acting Poppet Type Cartridge Check Valve

JCX10-03

PRODUCT INTRODUCTION:

Direct Acting Poppet Type Cartridge Check Valve. Main use is as a blocking or load-holding device.

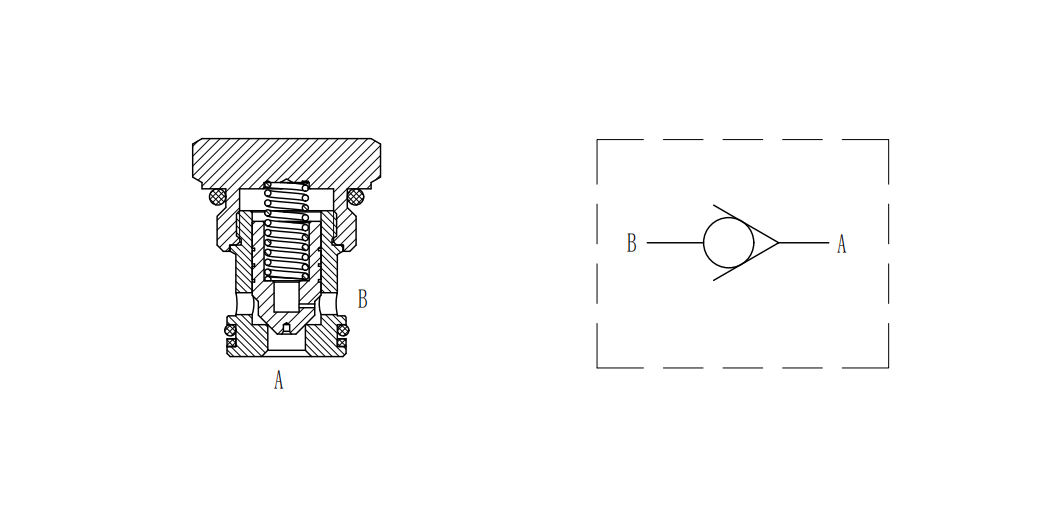

OPERATION:

When the fluid enters the Cartridge Check Valve from the oil inlet, the fluid pressure overcomes the spring force, pushing the valve core away from the valve seat, allowing the fluid to flow out from the oil outlet; when the oil inlet pressure decreases or the oil outlet pressure is higher than the oil inlet pressure, the spring force pushes the valve core back to the valve seat, closing the valve port and preventing the fluid from flowing back.

FEATURES:

Single and dual pilot pistons available to create pilot to open check

Fast response speed: Due to the direct-acting structure, there is no complex structure such as the pilot control oil circuit. The valve core moves directly under the action of the fluid pressure, so the response speed is fast and can be opened and closed quickly, which is suitable for systems with high response time requirements.

Compact structure: The threaded plug-in design makes it small in size. When installing, you only need to screw the Cartridge Check Valve into the installation hole of the system, which does not require a large space, which is conducive to the miniaturization and integrated design of the system.

Good sealing performance: Precision machining and reasonable sealing structure design are usually used between the valve core and the valve seat, which can achieve good sealing in the closed state and effectively prevent reverse leakage of the fluid.

High reliability: The structure is simple, there are no excessive moving parts and complex control links, so the reliability is high, the service life is long, and it can work stably in harsh working environments.

SPECIFICATIONS:

Max.Working Pressure:315bar(4568psi)

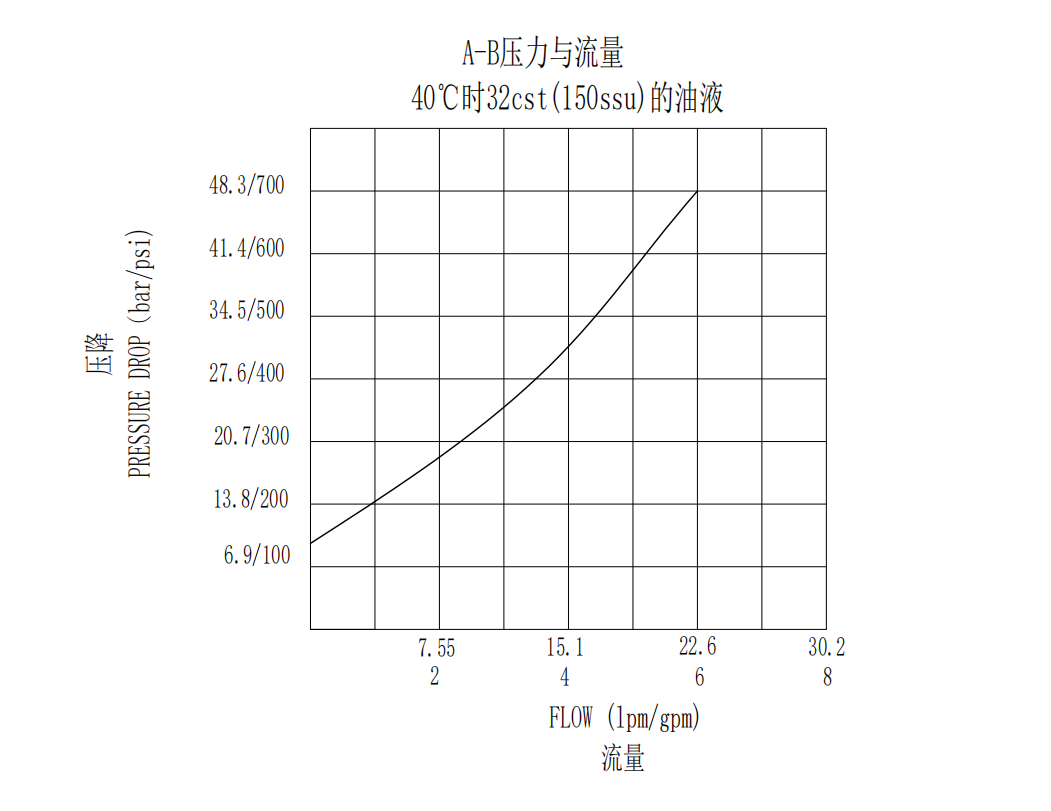

Flow:See performance curve.

Internal leakage:At 210bar(3045psi), the leakage is ≤2 drops/min.

Standard opening pressure:9±1bar(131psi)

Filtering Accuracy: 25 μ m.

Service Temperature:-40℃~ 120℃(NBR),-26℃~ 204℃(FKM)

Medium: Mineral oil with viscosity of 7.4 ~ 420 CST (50-2000) ssu or synthetic oil with lubricating function.

CHARACTERISTIC:

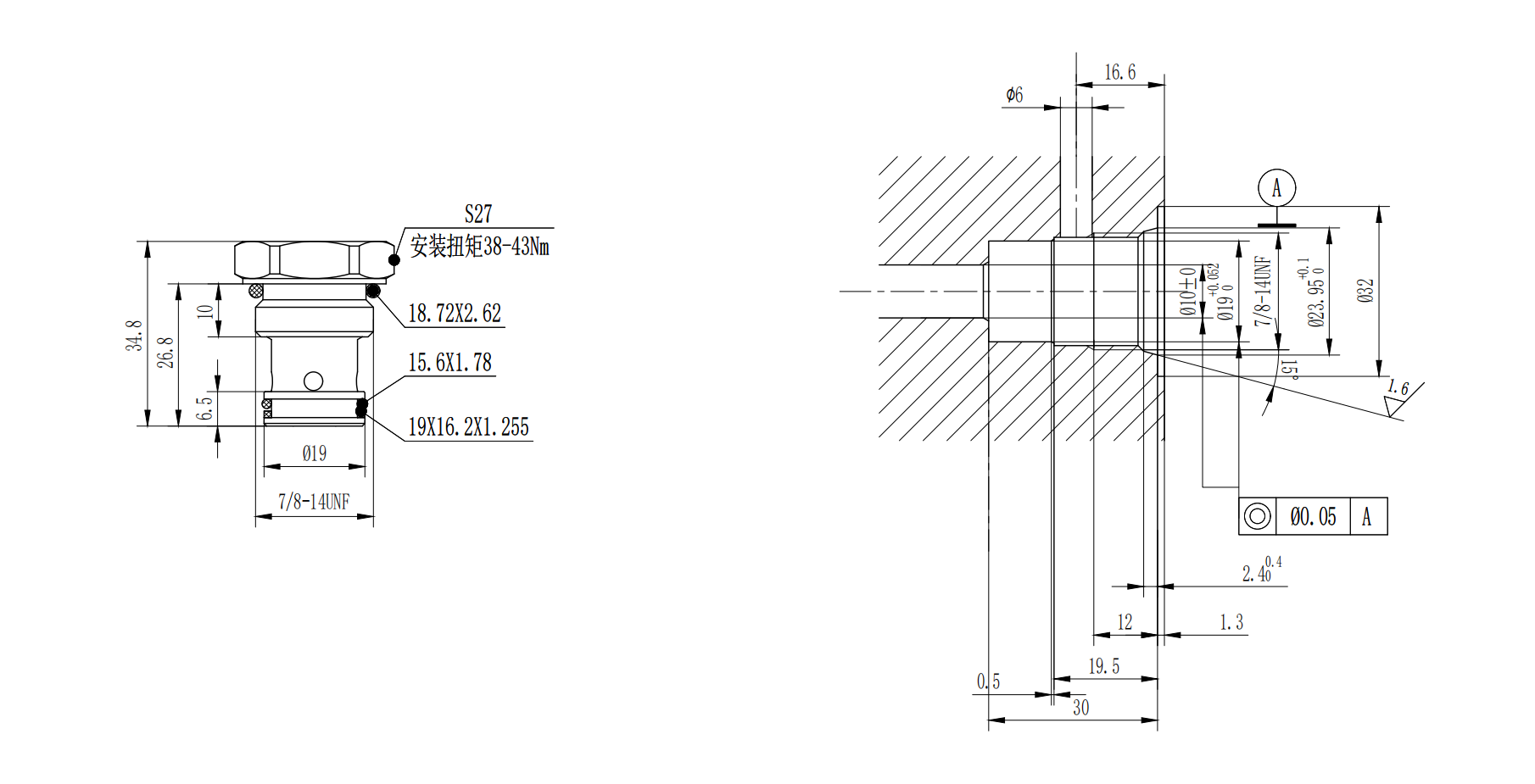

DIMENSIONS:

Application Areas:

Cartridge check valves are widely used in industrial hydraulic systems (such as oil cylinder pressure maintenance and backflow prevention for construction machinery and machine tools), agriculture and special vehicles (lifting of agricultural implements, stabilization of vehicle-mounted outriggers), petrochemical equipment (drilling platform blowout prevention, lubrication system pressure maintenance), aerospace and shipbuilding industries (one-way flow control for aircraft landing gear and ship steering gear), and hydraulic test benches. Its advantages are compact structure, easy installation and maintenance, and meeting the needs of one-way fluid control under complex working conditions such as high pressure and vibration.