The 7600 Series High Pressure Large Displacement Roller Bearing Pumps And Motors features a large displacement in a large frame. It is constructed from high strength cast iron with high strength alloy steel gear shaft and shaft sets.

High Pressure Large Displacement Roller Bearing Pumps And Motors

7600 SERIES High Pressure Large Displacement Roller Bearing Pumps And Motors

FEATURES:

The 7600 Series High Pressure Large Displacement Roller Bearing Pumps And Motors features a large displacement in a large frame. It is constructed from high strength cast iron with high strength alloy steel gear shaft and shaft sets.

The maximum pressure of this series of Roller Bearing Pumps and Motors can reach 25 MPa

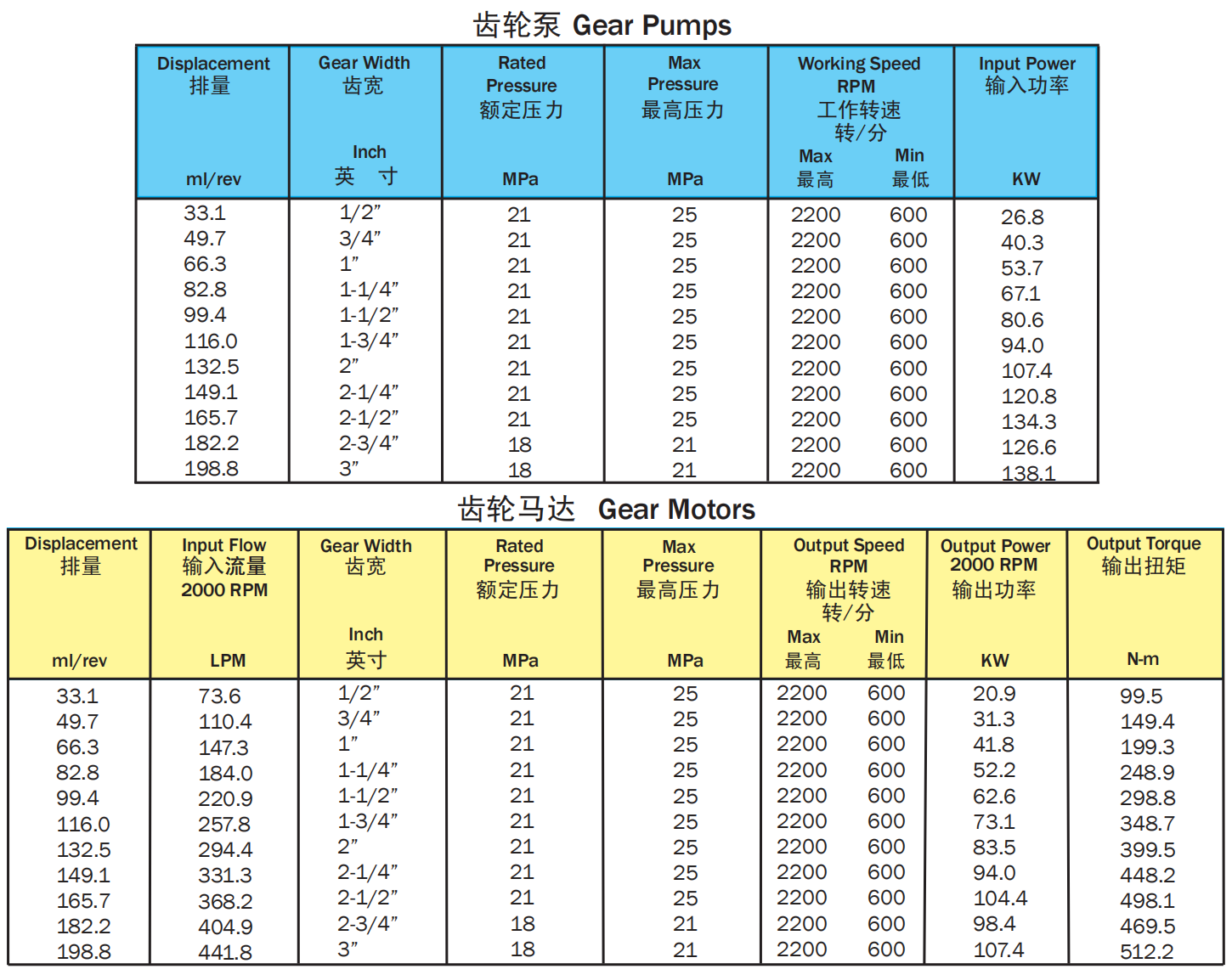

The displacement ranges from 33.1 ml/r to 198.8 ml/r

The pump and motor have various connection forms, and the connection size conforms to the SAE standard

It can be designed as a single pump or a multi-pump according to user requirements

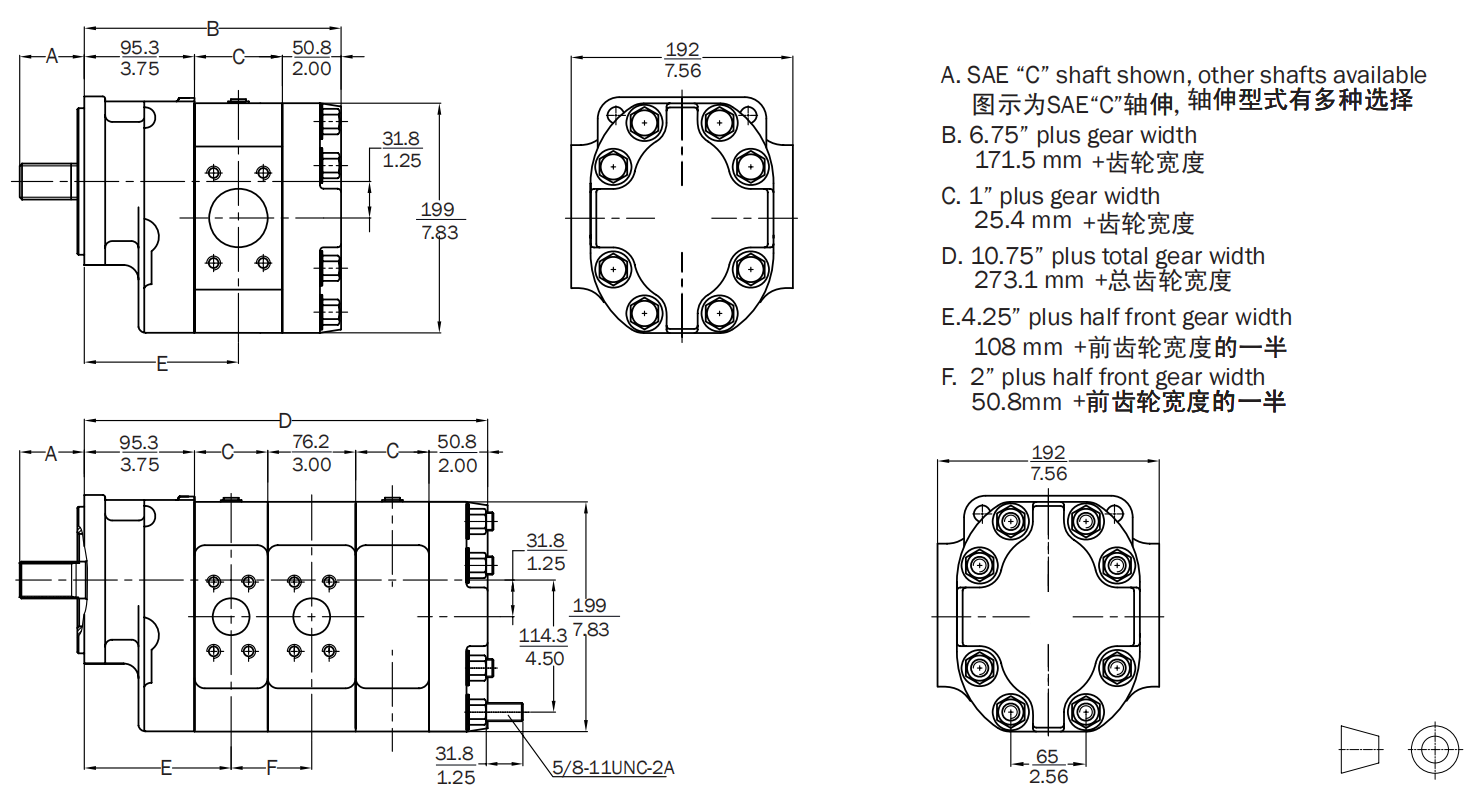

DIMENSIONAL DATA(mm/in):

PERFORMANCE:

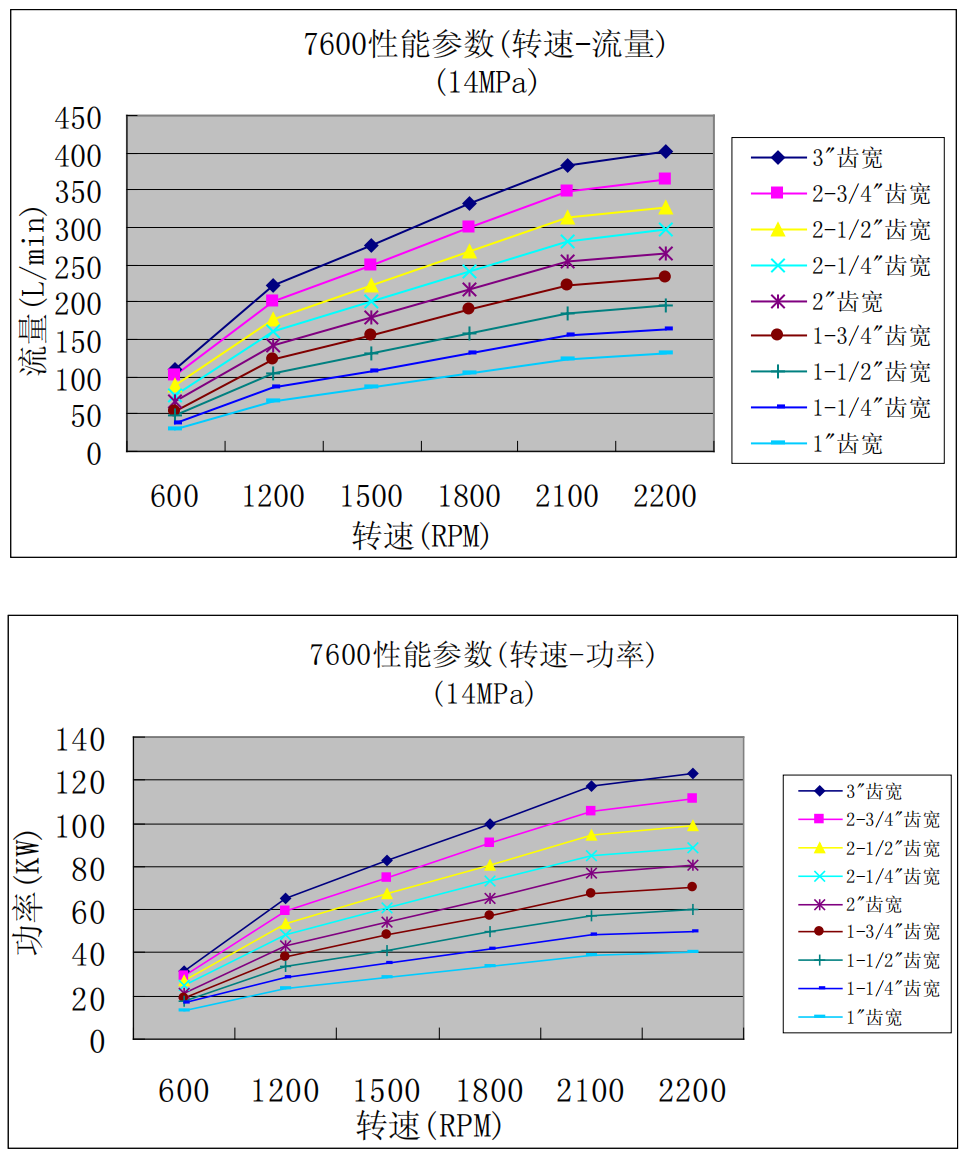

PERFORMANCE CURVE:

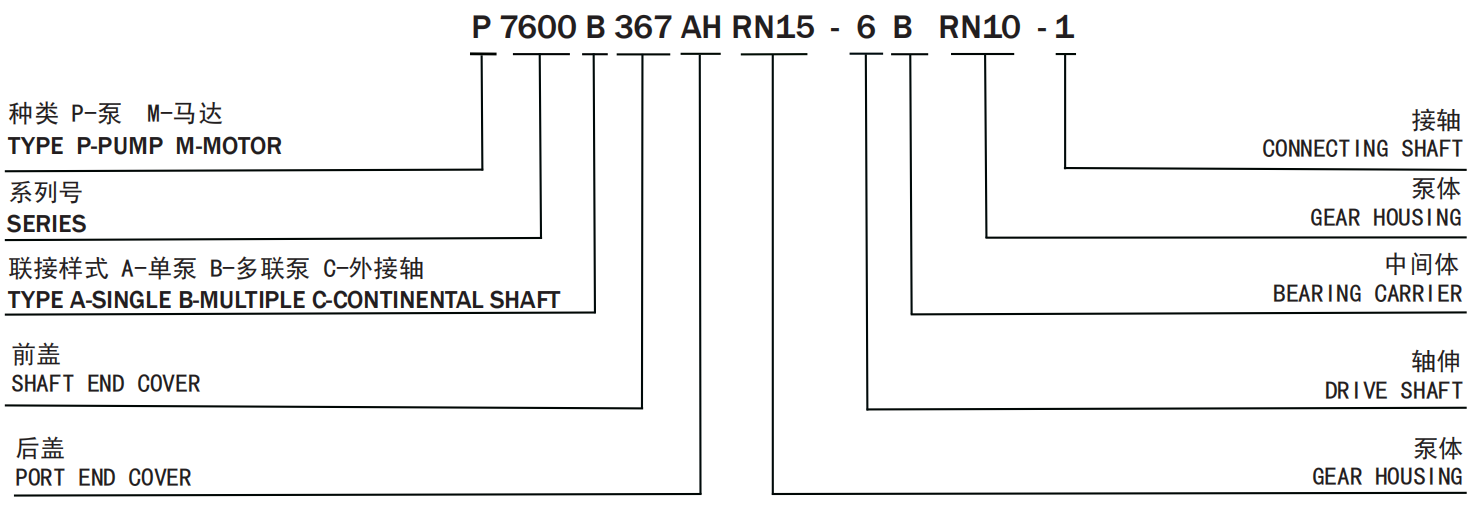

STANDARD MODEL IDENTIFICATION:

Application Areas:

Construction machinery: excavators, loaders, bulldozers, cranes, forklifts (travel drive, working device hydraulic system).

Agricultural machinery: large tractors, combine harvesters, forestry machinery.

Mining machinery: rock drilling rigs, underground scrapers, crushers.

Material handling: port machinery (such as reach stackers), heavy forklifts.

Industrial hydraulics: large presses, injection molding machines, metallurgical equipment, ship deck machinery.

Travel machinery drive: as pumps and motors in hydrostatic transmission (HST) systems.

Selection and use considerations:

System matching: Ensure that the pressure, displacement, and speed range of the selected pump/motor match the system requirements.

Oil cleanliness: The high-pressure system has extremely high requirements for oil cleanliness. High-precision oil filters must be used and maintenance procedures must be strictly followed to protect precision rolling bearings and friction pairs.

Installation and maintenance: Strictly follow the manufacturer's instructions for installation, alignment, oiling, and maintenance, especially to ensure that the bearings are fully lubricated.

Advantages:

High performance: Designed for high pressure and high flow/torque requirements.

High reliability: Rolling bearing design significantly improves load capacity, efficiency and life under harsh conditions.

Rugged and durable: Suitable for heavy-duty industrial applications and mobile machinery.

Efficient: Rolling bearings reduce friction losses and optimize volumetric and mechanical efficiency.

Dual functionality: Provides pump and motor options to meet the dual needs of system power source and actuator.

Low noise: Special design and manufacturing process make the product low noise during operation, reducing noise pollution to the working environment.