The 124 Series High Pressure Small Displacement Sleeve Bushing Pumps And Motors are a heavy-duty sleeve bushing design in a small frame size.leeve Bushing Pumps and Motors housings are doweled to withstand higher pressures and are built using high strength cast iron construction.

High Pressure Small Displacement Sleeve Bushing Pumps And Motors

124 SERIES High Pressure Small Displacement Sleeve Bushing Pumps And Motors

FEATURES:

The 124 Series High Pressure Small Displacement Sleeve Bushing Pumps And Motors are a heavy-duty sleeve bushing design in a small frame size.leeve Bushing Pumps and Motors housings are doweled to withstand higher pressures and are built using high strength cast iron construction.

Heavy duty sleeve bushing design in a small frame size

Working pressure up to 3500 PSI

Cubic inch displacements from 0.62 through 2.48

Speeds up to 3000 RPM

Flows up to 30 GPM

Doweled and high strength cast iron construction

High strength alloy steel gear and shaft sets

NPT, ORB, Split ports are available

Pressure balanced wear plates maintain high pump efficiency throughout all operating ranges

Both single inlet/single outlets and single inlet/dual outlet bearing carriers

100% factory tested

Available as a clutch pump

Available as a fan motor

High pressure 424 verison available in select sizes

The 124 series High Pressure Small Displacement Sleeve Bushing Pumps And Motors are widely used in Car Haulers、Crane Equipment Vehicles、Roll Off Trucks、Refuse Collection、Snow Plows &Spreaders

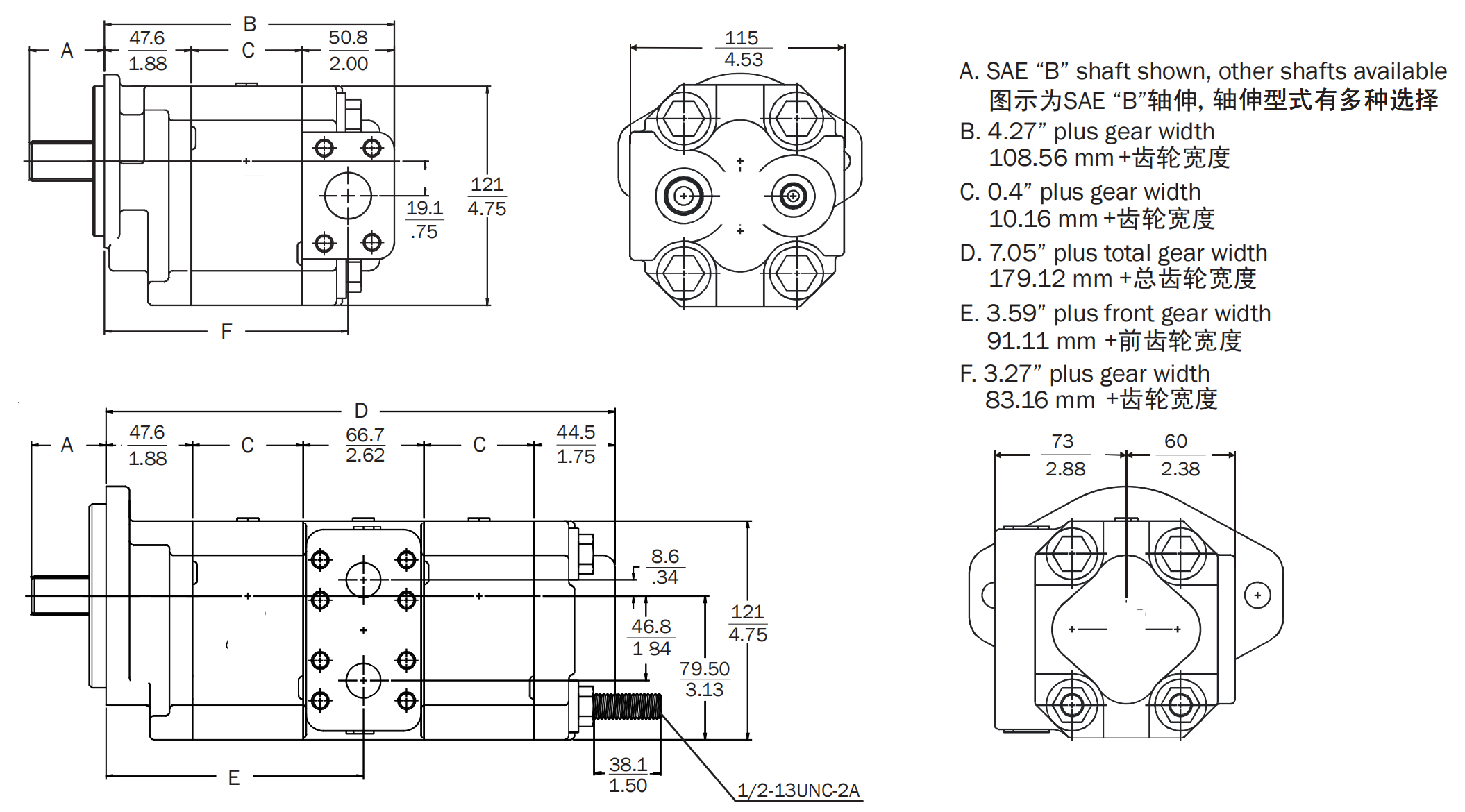

DIMENSIONAL DATA(mm/in):

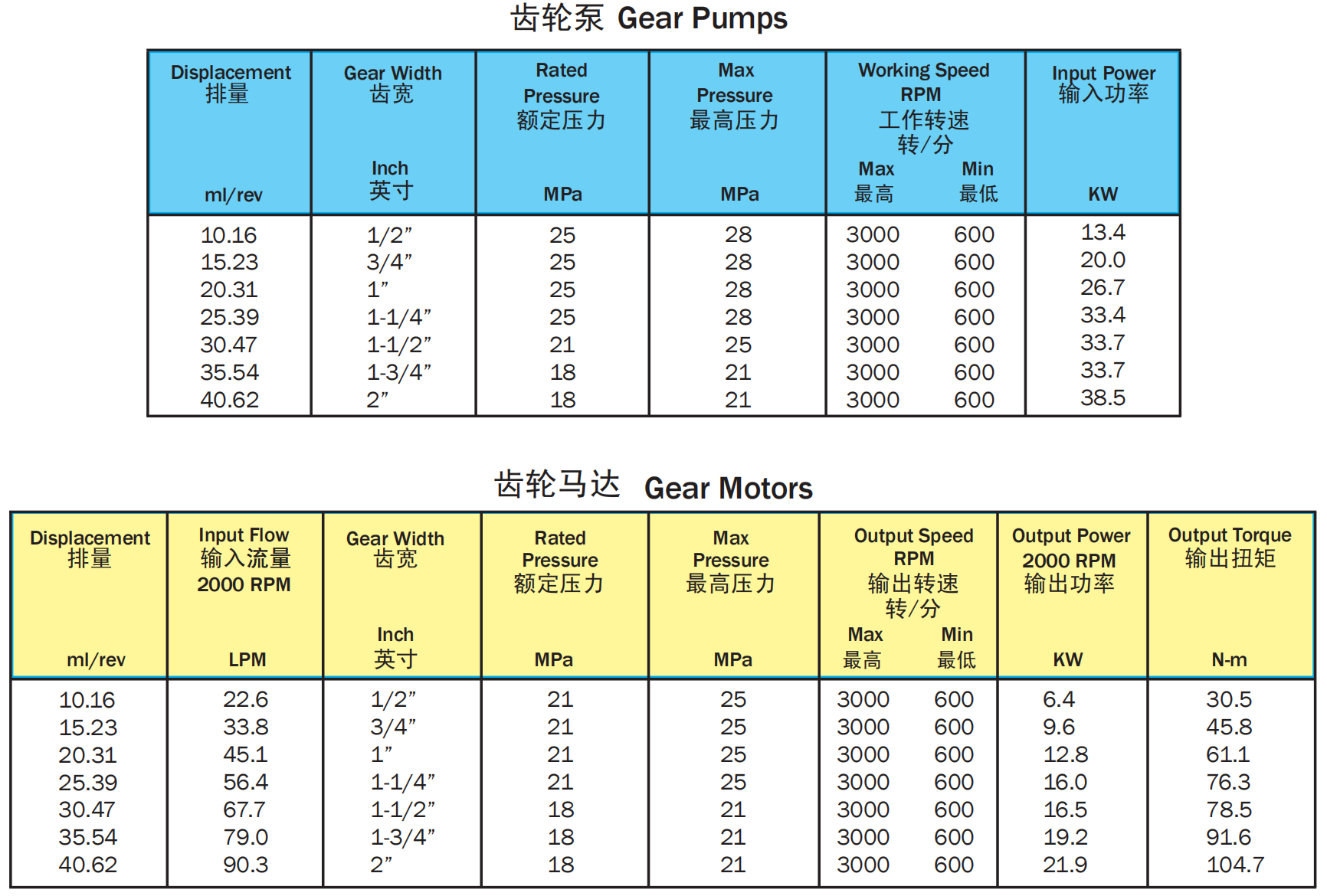

PERFORMANCE:

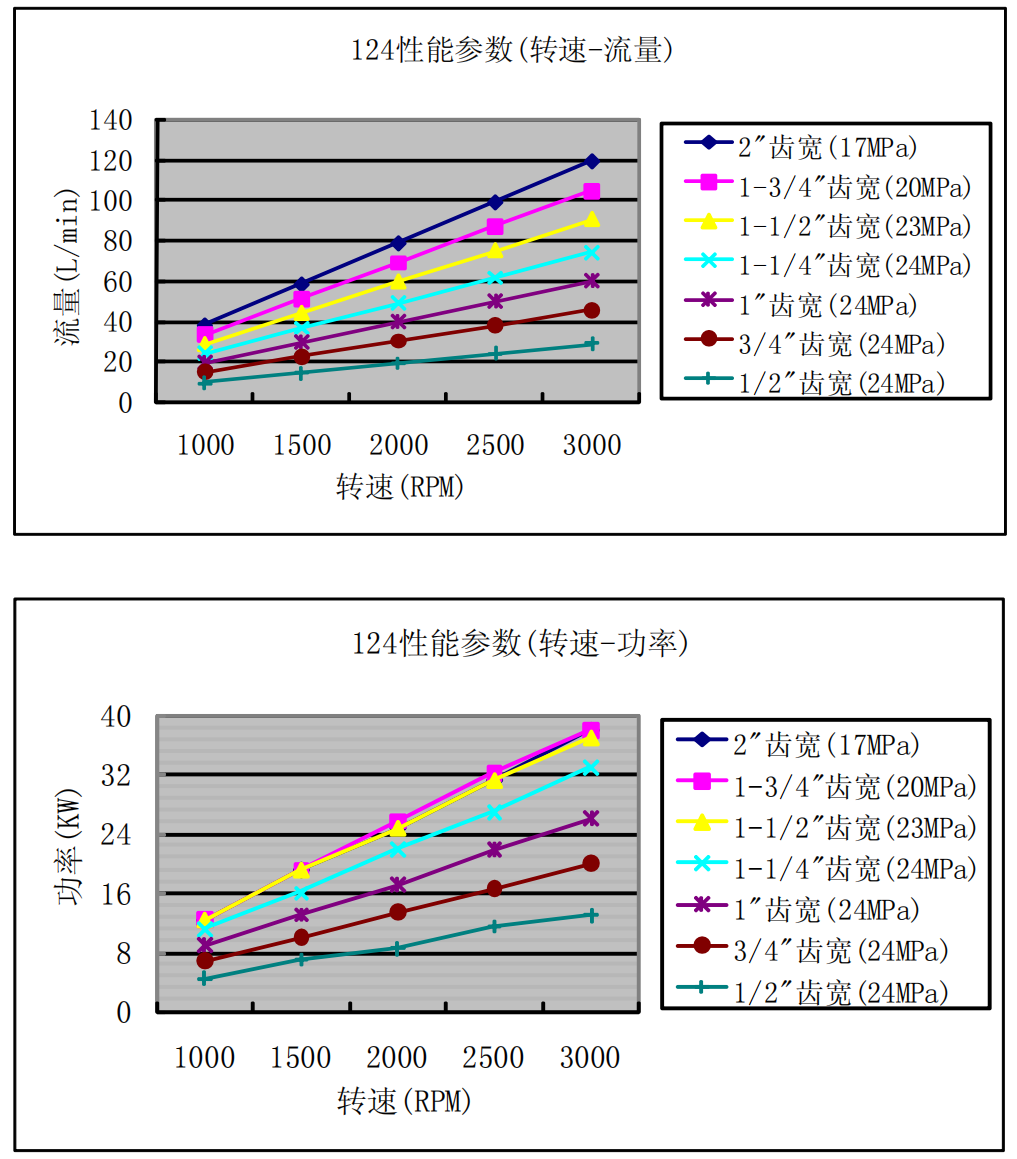

PERFORMANCE CURVE:

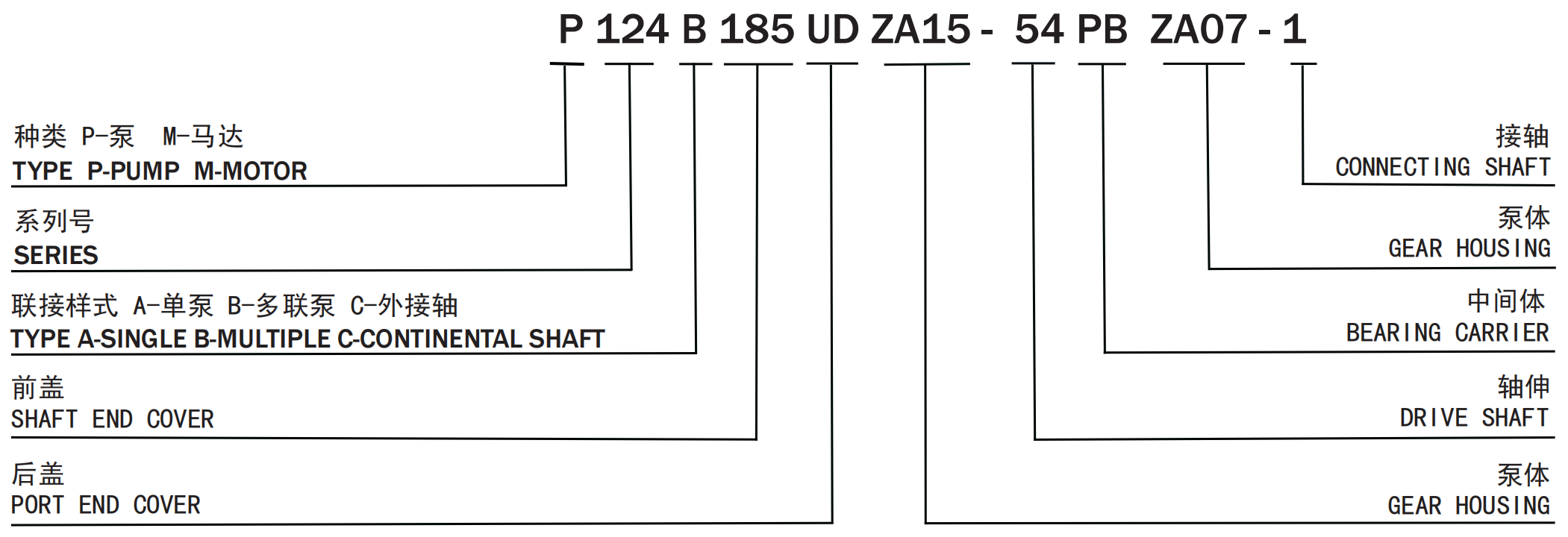

STANDARD MODEL IDENTIFICATION:

Features:

Sliding bearing: The gear shaft is supported by a sliding bearing, which has good load-bearing capacity and wear resistance, can withstand radial and axial forces under high pressure, and ensure the smooth operation of the gear. At the same time, the friction coefficient of the sliding bearing is small, which can reduce energy loss and improve efficiency.

High-strength gears: Gears and gear shafts are made of high-strength alloy steel to withstand meshing stress under high pressure, ensuring the reliability and service life of gear pumps and motors under high-pressure conditions.

Pressure balance side plate: The pressure balance wear-resistant side plate is set to balance the axial and radial forces during the operation of the gear pump and motor, reduce the wear of gears and bearings, improve the efficiency and stability of the pump and motor, and enable it to always maintain high-efficiency output.

Compact structure: The overall structure is relatively compact, small in size, light in weight, easy to install and use, and suitable for work occasions with limited space.

High-pressure bearing capacity

High-pressure small-displacement gear pumps and motors achieve high-pressure working capacity by optimizing gear parameters and using high-strength materials. Sliding bearings (through bidirectional sealing structure and special lubrication design, can withstand radial loads under high pressure while reducing friction loss.