The 3100 Series High Pressure Gear Pumps and Motors features a large displacement in a large frame. It is constructed from high strength cast iron with high strength alloy steel gear shaft and shaft sets.

High Pressure Roller Bearing Pumps And Motors

3100 SERIES High Pressure Gear Pumps and Motors

FEATURES:

The 3100 Series High Pressure Gear Pumps and Motors features a large displacement in a large frame. It is constructed from high strength cast iron with high strength alloy steel gear shaft and shaft sets.

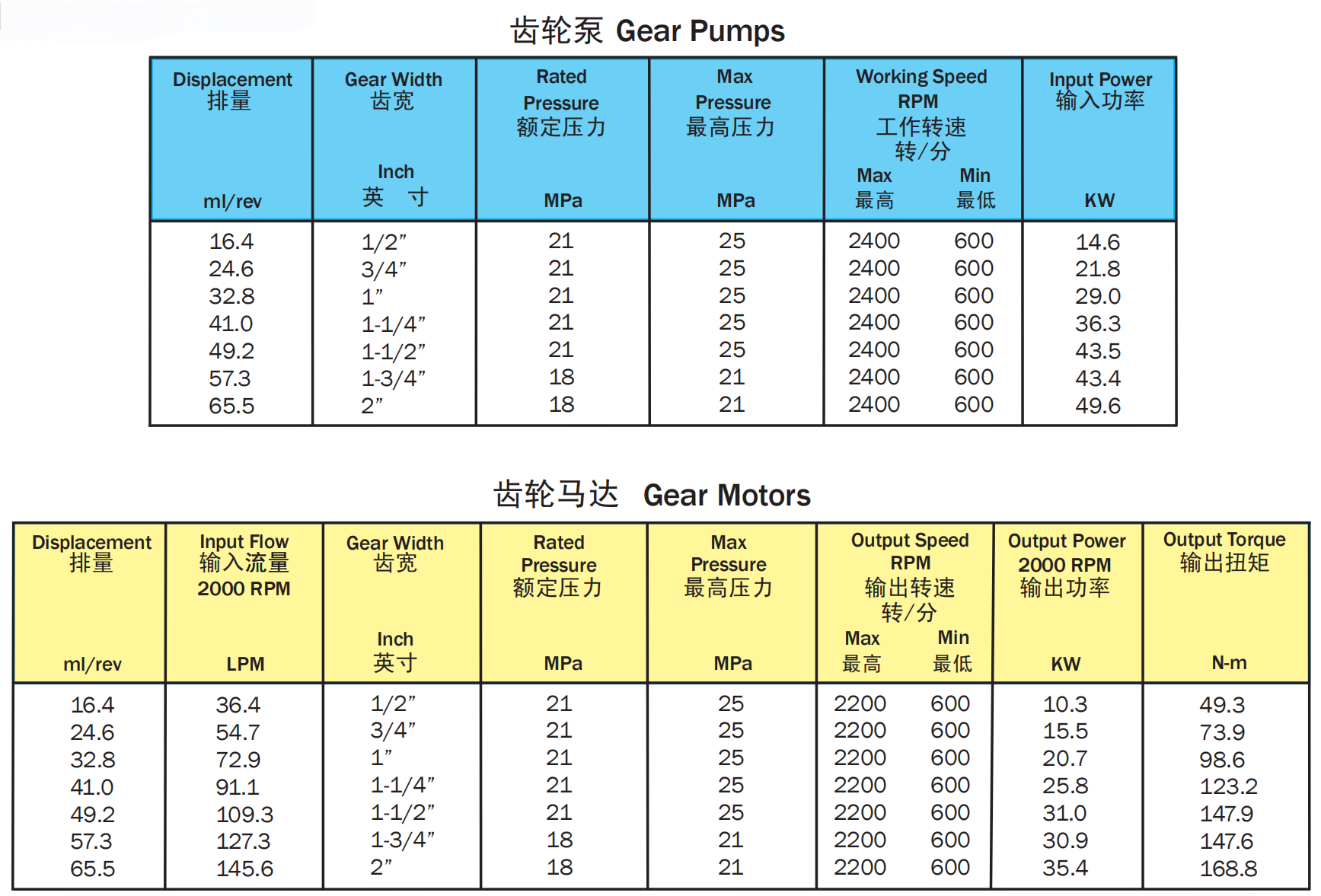

The maximum pressure of this series of High Pressure Gear Pumps and Motors can reach 25 MPa

The displacement ranges from 16.4 ml/r to 65.5 ml/r

The pump and motor have various connection forms, and the connection size conforms to the SAE standard

It can be designed as a single pump or a multi-pump according to user requirements

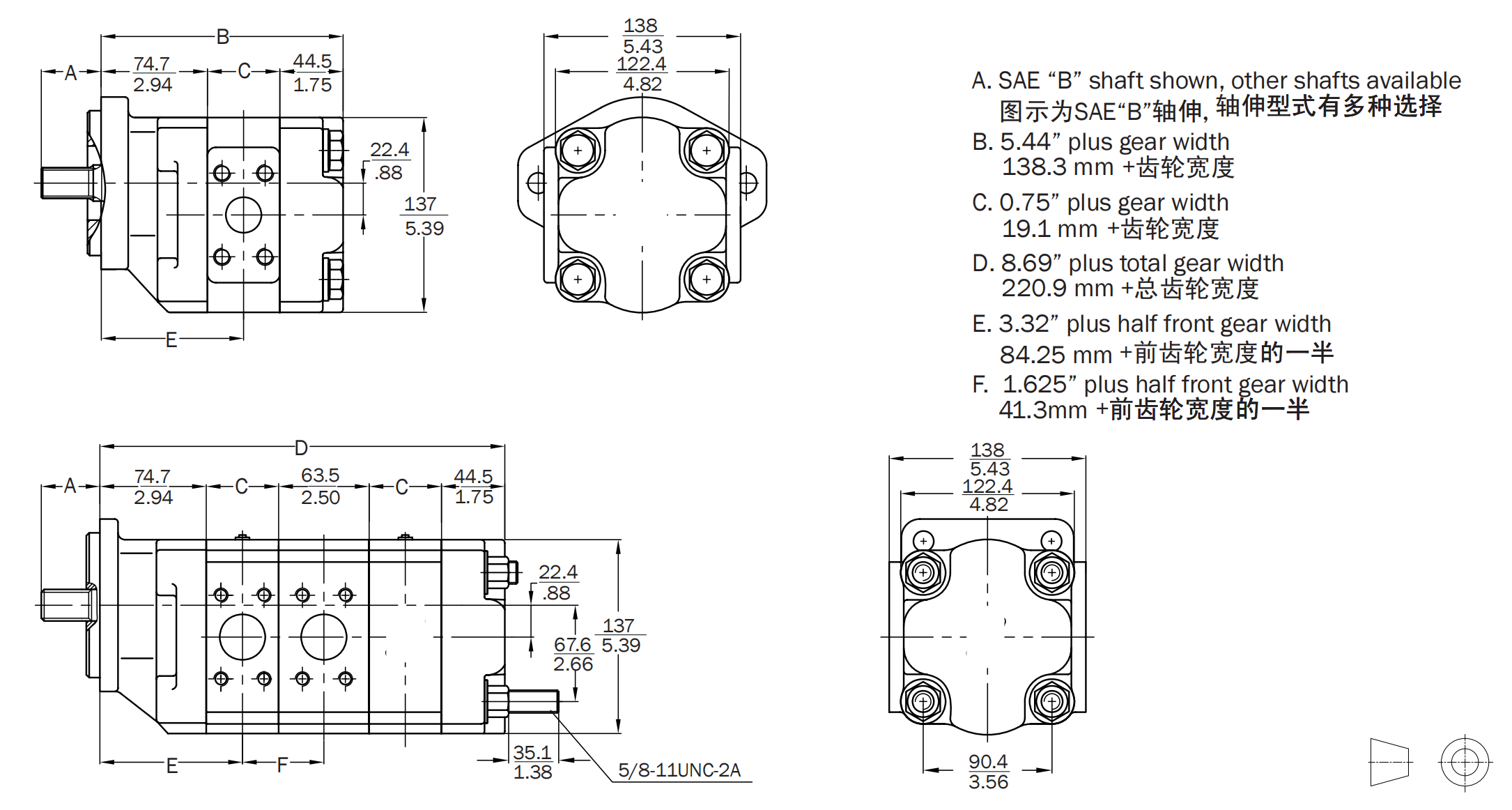

DIMENSIONAL DATA(mm/in):

PERFORMANCE:

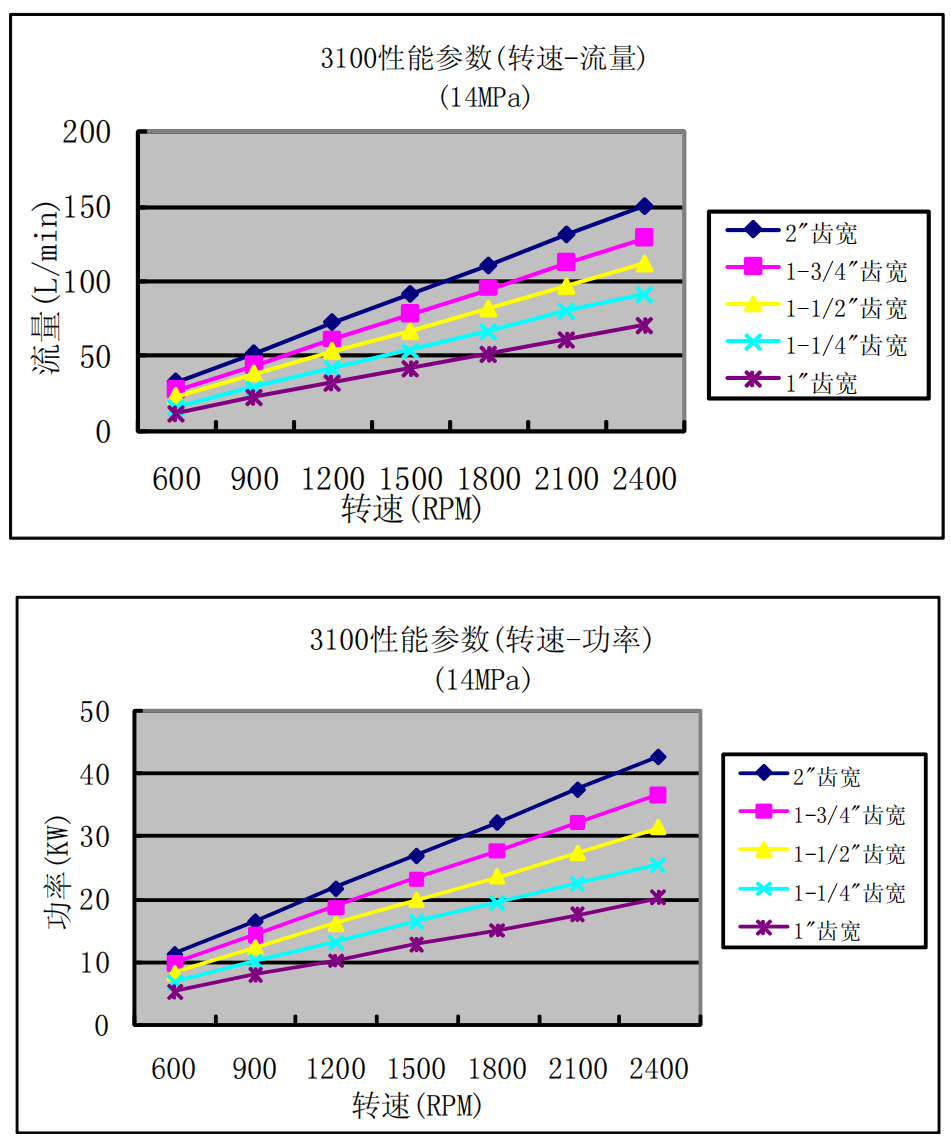

PERFORMANCE CURVE:

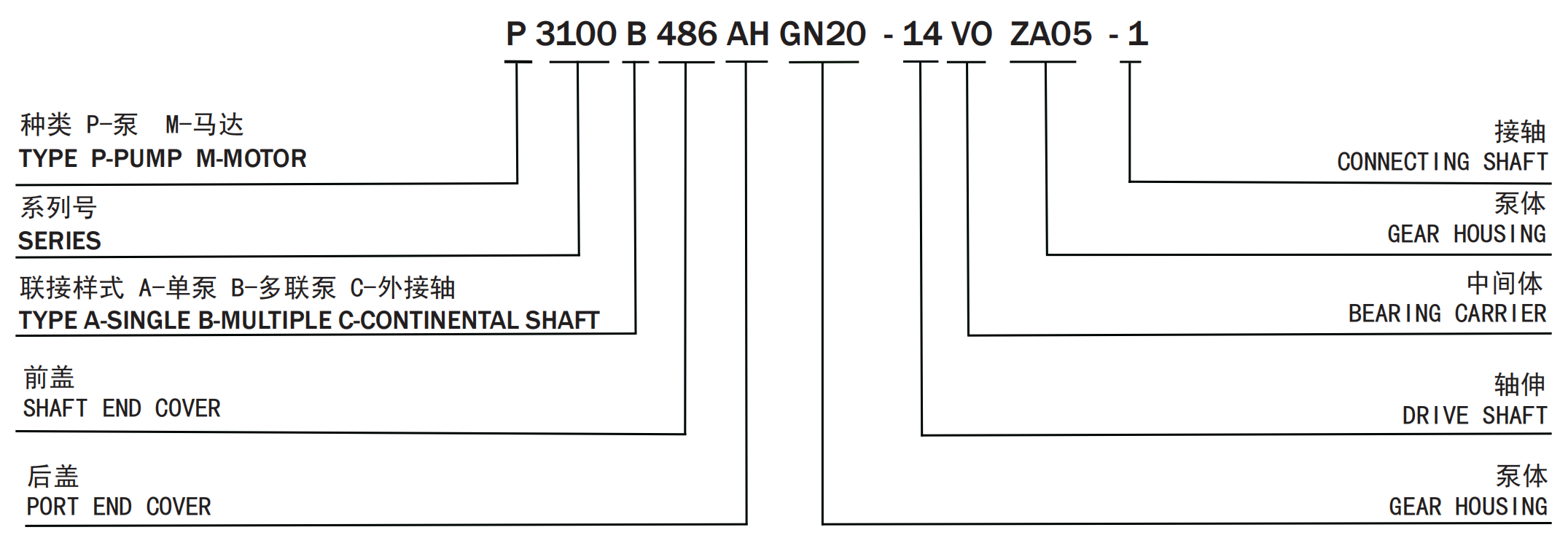

STANDARD MODEL IDENTIFICATION:

Structural features:

Rolling bearing design: Rolling bearings are used to replace traditional sliding bearings. Rolling bearings have the advantages of low friction coefficient, high efficiency, long life, etc. They can adapt to higher speeds and loads, reduce energy loss, and improve the overall performance of the equipment.

Sleeve structure: A pair of mutually meshing gears with shafts at both ends and sleeves with bearings are all installed in the housing. This structure can better maintain the concentricity between the front bearing and the rear bearing, making the gear transmission more stable and reducing vibration and noise.

"8" shaped inner cavity design: The inner cavity of the housing is designed in the shape of "8", and the two sleeves with a complete "8" shape that fit each other are embedded in the inner cavity of the housing without gaps, effectively preventing the deformation of the sleeve and the generation of abnormal noise.

Special side plate structure: The side plate is provided with a high-pressure oil axial sealing mechanism composed of the side plate itself and the sealing rubber ring and sealing retaining ring installed thereon, so that the high-pressure oil is limited between the two side plates, avoiding the sleeve from bearing the radial liquid pressure of the high-pressure oil, and ensuring the normal operation of the bearing.

Product advantages:

High-pressure performance: The maximum continuous use pressure can reach 25MPa or even higher, which can meet the working requirements of various high-pressure hydraulic systems.

Large displacement output: A wide range of displacement can meet the needs of large mechanical equipment for large flow.

High efficiency: Advanced structural design and the application of rolling bearings reduce energy loss, improve the volumetric efficiency and mechanical efficiency of pumps and motors, make the system's energy utilization rate higher, and operate more economically and energy-saving.

High reliability: Key components such as bearings and sealing elements are made of high-quality materials and advanced manufacturing processes, which improves the reliability and service life of the product, reduces the probability of failure, and reduces maintenance costs.

Strong adaptability: It can be composed of multi-stage pumps to meet different hydraulic system configuration requirements. At the same time, the product has low noise, compact appearance, and beautiful appearance. It is suitable for hydraulic machinery operating in various harsh working conditions, such as construction machinery, mining machinery, agricultural machinery, etc.