The 5100/124 series High Pressure Bearing Gear Pumps are cross-series multi-pumps that connect large displacement pumps and small displacement pumps in series.

High Pressure Roller Bearing Pumps

5100/124 SERIES High Pressure Roller Bearing Gear Pumps

FEATURES:

The 5100/124 series High Pressure Bearing Gear Pumps are cross-series multi-pumps that connect large displacement pumps and small displacement pumps in series.

The rear pump can be equipped with a safety valve to make the hydraulic system simpler

The maximum pressure of this series of High Pressure Roller Bearing Gear Pumps can reach 28 MPa

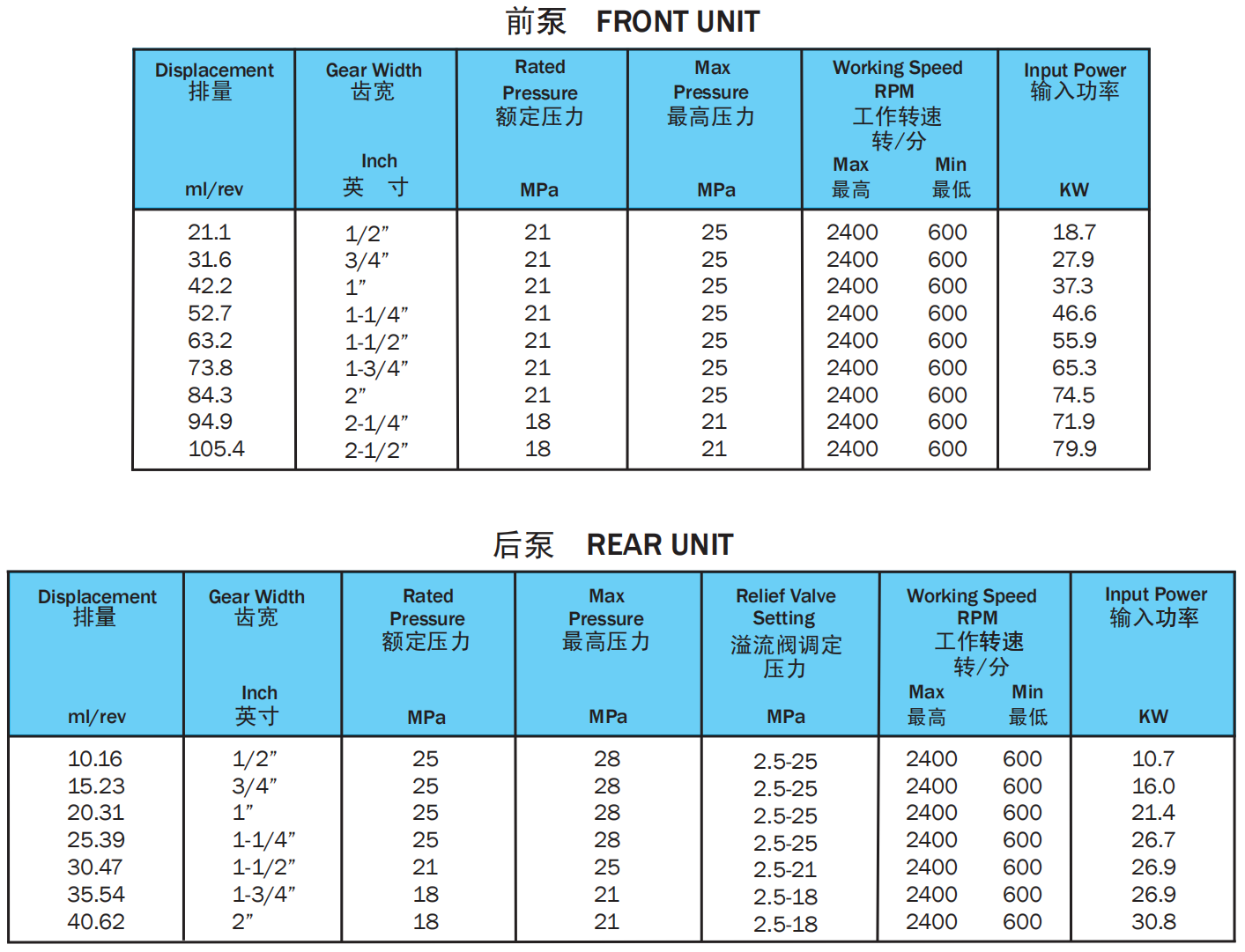

The displacement ranges from 10.16 ml/r to 105.4 ml/r

There are various connection forms, and the connection size meets the SAE standard

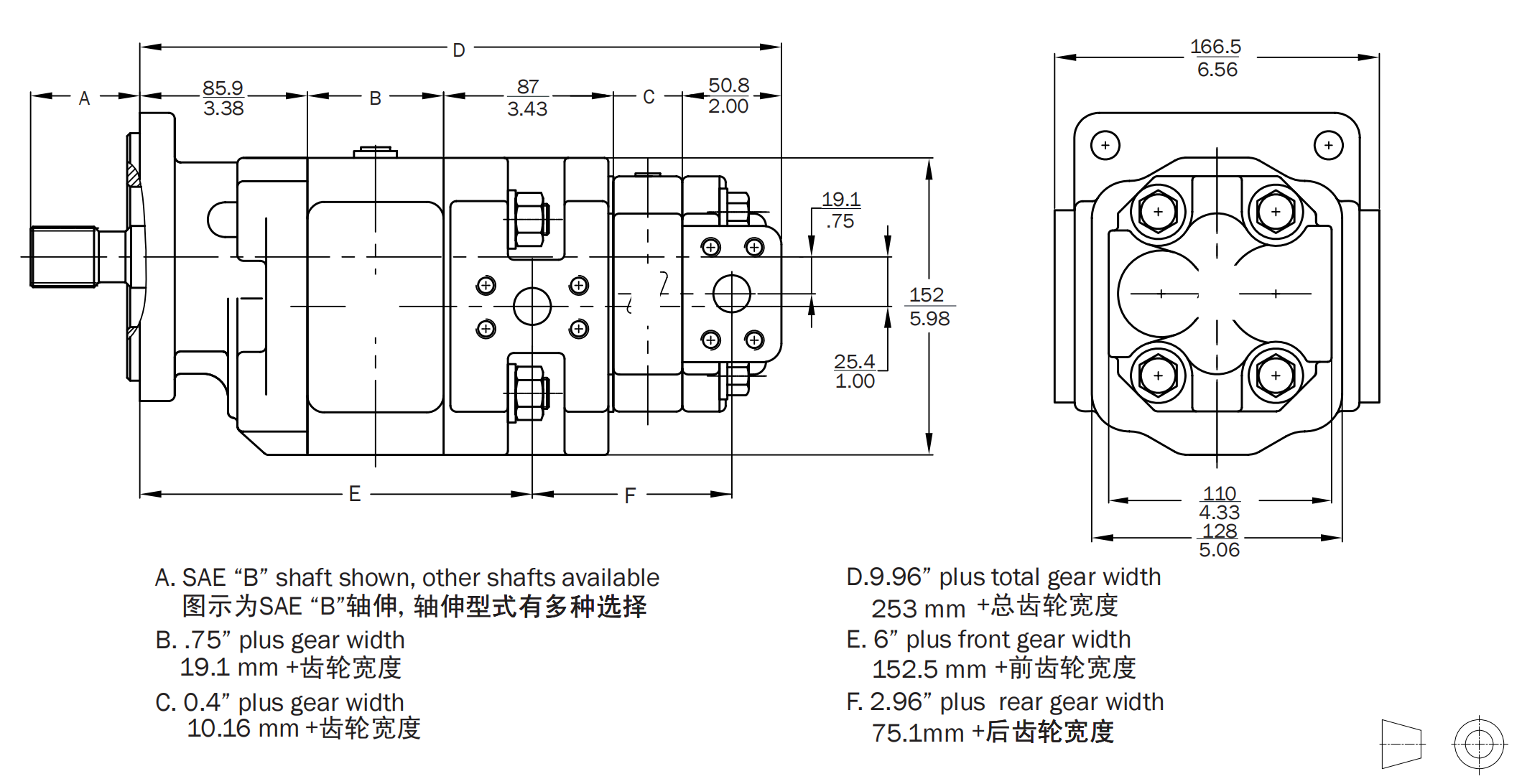

DIMENSIONAL DATA(mm/in):

PERFORMANCE:

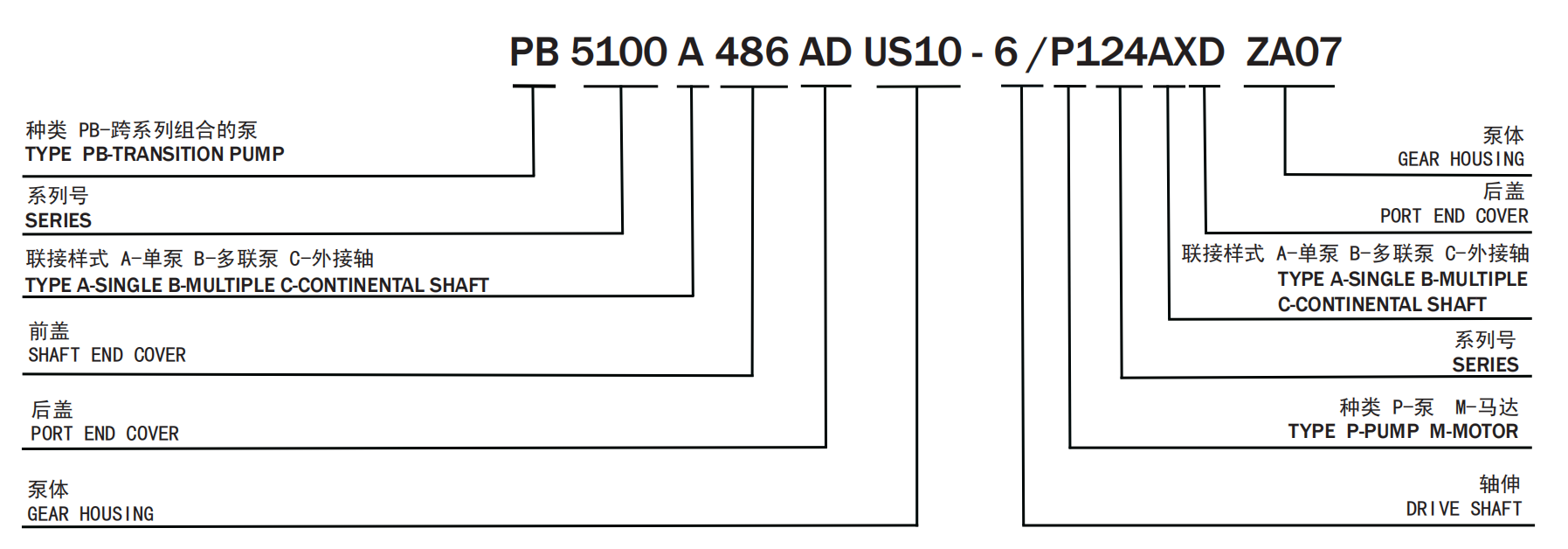

STANDARD MODEL IDENTIFICATION:

Core Advantages And Features:

High-pressure capability: Core advantage. The design pressure is up to 28MPa, which is much higher than that of ordinary sliding bearing gear pumps (usually in the range of 10-20 MPa). It is particularly suitable for high-pressure hydraulic systems.

High load-bearing capacity and long life: Rolling bearings can effectively withstand high loads, significantly reduce journal wear, and greatly extend the service life of the pump, especially under harsh working conditions.

High volumetric efficiency: Optimized clearance design, precise gear and bearing support enable the pump to maintain a high volumetric efficiency under high pressure, reduce internal leakage, and improve system energy efficiency.

High reliability: The sturdy structure, durable bearings and precision manufacturing ensure the stability and reliability of the pump under high pressure and high load, and reduce downtime.

Good anti-pollution ability: Compared with plunger pumps, gear pumps are relatively less sensitive to oil contamination, and the rolling bearing design also enhances its tolerance to certain pollutants (but good filtration is still necessary).

Compact structure and relatively low flow pulsation: (especially helical or herringbone gear design) provide relatively stable flow output.

Maintainability: Although the structure is slightly more complicated than that of ordinary gear pumps, the main components (bearings, shaft seals, gears) are usually replaceable and maintainability is good.

Application Areas:High Pressure Bearing Gear Pumps are widely used in industrial fields that require a reliable and continuous high-pressure oil source:

- Hydraulic system:

Working hydraulic system of construction machinery (excavators, loaders, cranes, bulldozers).

Main drive or auxiliary hydraulic system of machine tools (presses, injection molding machines, bending machines).

Hydraulic stations of metallurgical equipment (rolling mills, continuous casting machines).

Hydraulic systems of ships and marine engineering (steering gear, anchor winch, deck machinery).

Pressure testing equipment, hydraulic test benches.

Lubrication system: High-pressure centralized lubrication system of large equipment (such as wind turbines, mining machinery).