The 5100 Series High Pressure Roller Bearing Gear Pumps And Motors features a large displacement in a large frame. It is constructed from high strength cast iron with high strength alloy steel gear shaft and shaft sets.

High Pressure Roller Bearing Gear Pumps And Motors

5100 SERIES High Pressure Roller Bearing Gear Pumps And Motors

FEATURES:

The 5100 Series High Pressure Large Displacement Roller Bearing Pumps And Motors features a large displacement in a large frame. It is constructed from high strength cast iron with high strength alloy steel gear shaft and shaft sets.

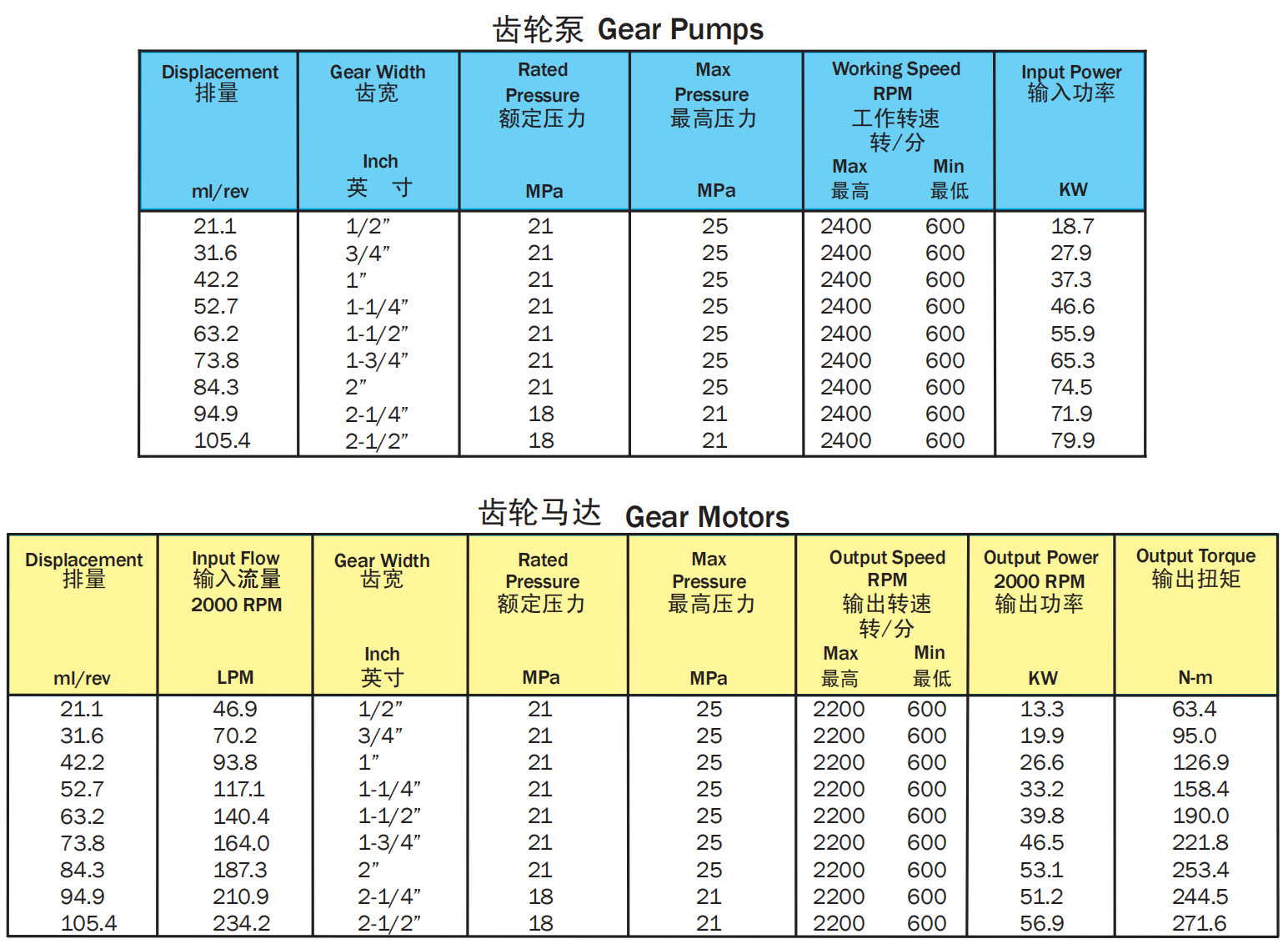

The maximum pressure of this series of High Pressure Pumps and Motors can reach 25 MPa

The displacement ranges from 21.1 ml/r to 105.4 ml/r

The pump and motor have various connection forms, and the connection size conforms to the SAE standard

It can be designed as a single pump or a multi-pump according to user requirements

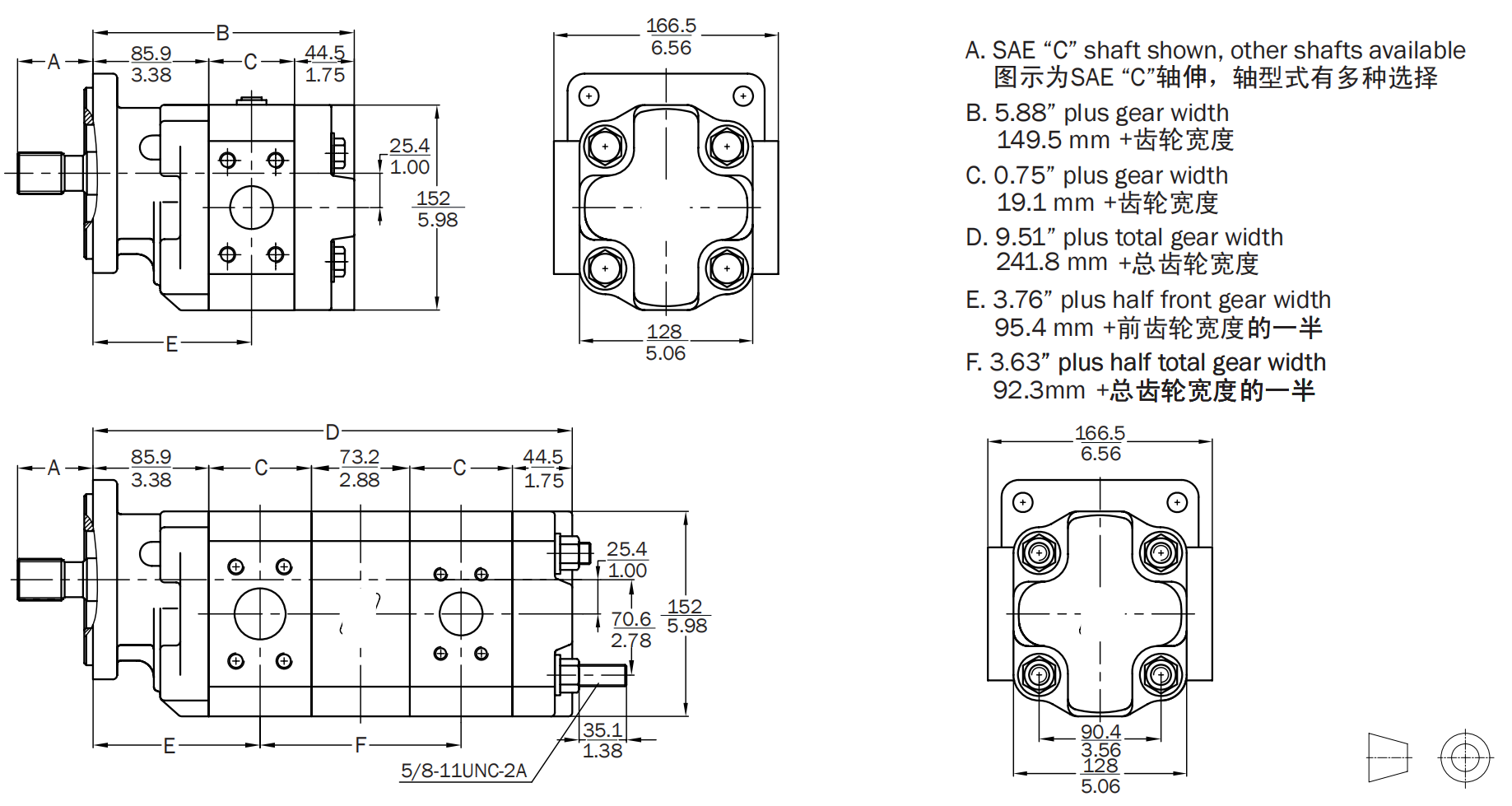

DIMENSIONAL DATA(mm/in):

PERFORMANCE:

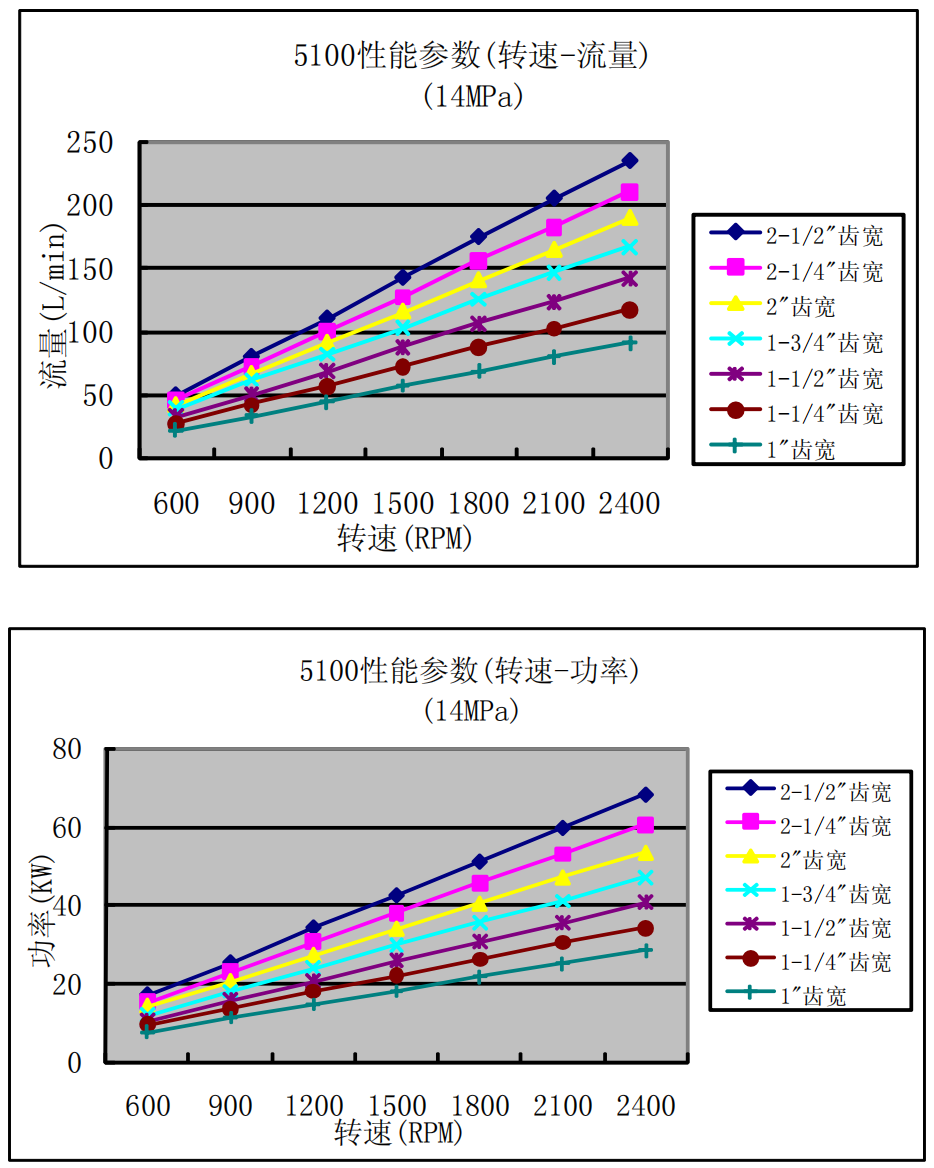

PERFORMANCE CURVE:

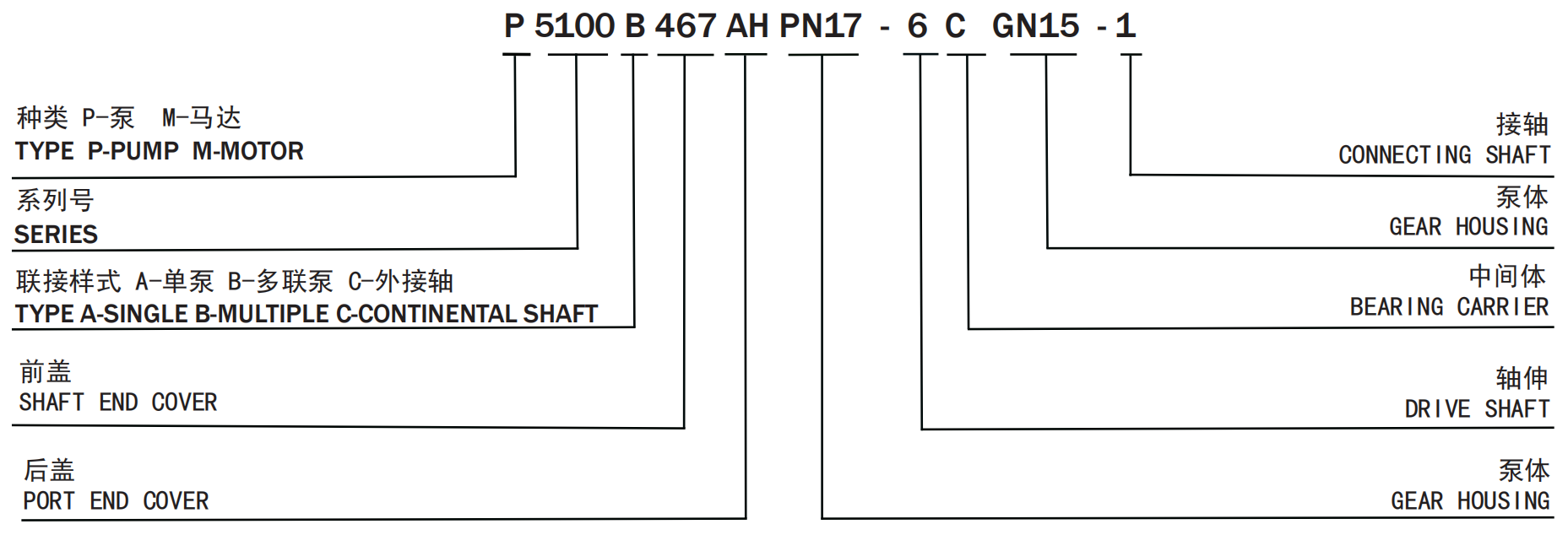

STANDARD MODEL IDENTIFICATION:

Working Principle Of Gear Pumps and Motors:

The working principle of the gear pump: it relies on the change and movement of the working volume formed between the pump cylinder and the meshing gear to transport liquid or increase its pressure. When the gear rotates, in the suction chamber, the gear teeth gradually disengage, so that the sealed volume gradually increases, forming a local vacuum, and the oil in the oil tank enters the suction chamber under the action of atmospheric pressure. As the gear rotates, the oil is brought to the discharge chamber; in the discharge chamber, the gear teeth gradually enter the meshing, so that the sealed volume gradually decreases, and the oil is squeezed out to form high-pressure oil discharge.

The working principle of the gear motor: in contrast to the gear pump, when the high-pressure oil enters the oil inlet chamber of the gear motor, because the meshing point radius is smaller than the tooth circle radius, an unbalanced liquid pressure is generated on the tooth surface, thereby forming a torque, driving the gear to rotate, dragging the external load to do work, and converting hydraulic energy into mechanical energy.

Application Areas Of Gear Pumps and Motors:

Engineering machinery: Gear Pumps and Motors are widely used in excavators, loaders, bulldozers, vibratory rollers and other equipment to provide power for their working devices to achieve tasks such as excavation, loading, bulldozing, and compaction.

Mining machinery: Equipment such as mine hoists, underground loaders, crushers, etc. require High Pressure Pumps and Motors to drive to meet the needs of mining and ore transportation.

Agricultural machinery: High Pressure Pumps and Motors can be used in the hydraulic systems of agricultural machinery such as tractors, combine harvesters, and rice transplanters to control the lifting, rotation, and harvesting of agricultural implements.